Why High-Availability PLC Systems Are Essential for Industrial Plants

High-availability PLC systems have become the backbone of modern industrial plants where even a few seconds of downtime can lead to costly disruptions. As automation evolves and plants become more data-driven, the need for highly reliable and resilient control systems grows stronger. Components such as BMEH584040S and energy-monitoring tools like METSEPM5111 play a vital role in maintaining seamless performance, efficiency, and safety. This article explores why these systems are indispensable and how they support mission-critical operations.

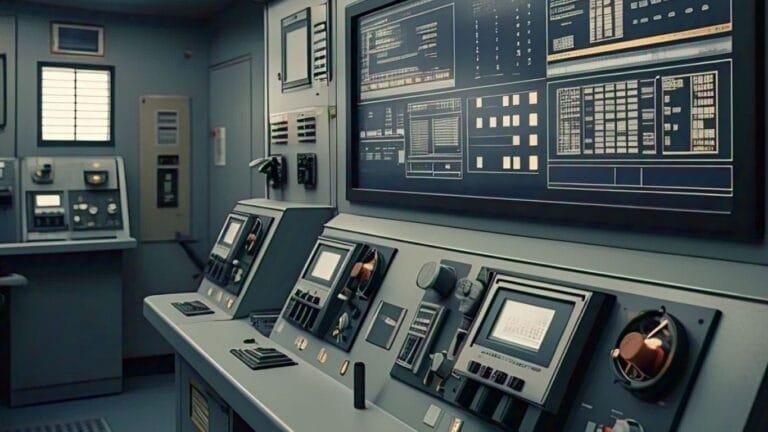

Understanding High-Availability PLC Systems

High-availability PLC systems are designed to ensure continuous operation by reducing failure risks and enabling quick recovery from unexpected faults. These systems are engineered for industries where precision, uptime, and safety are non-negotiable.

What Makes a PLC System High-Availability?

High-availability PLCs typically include redundancy, real-time diagnostics, fault-tolerant architecture, and robust data communication. Components such as the BMEH584040S, used for advanced processing and safety-critical control, elevate the reliability of these systems. With advanced modules and redundant communication paths, industrial processes continue smoothly even if one part of the system fails.

Why Modern Plants Demand Higher Reliability

Today’s industrial plants operate at higher speeds and manage more complex operations than ever before. Automation lines, robotics, smart sensors, and analytics platforms all depend on continuous data flow and processing. A single failure in the PLC architecture can interrupt production, compromise safety, and cause substantial financial losses. Therefore, next-generation components and monitoring tools like the METSEPM5111 help maintain uninterrupted operations.

The Critical Importance of High-Availability PLC Systems

High-availability PLC systems deliver far more than uptime. They contribute to efficiency, cost savings, predictive maintenance, and overall operational excellence.

Minimizing Downtime and Production Losses

In industries such as manufacturing, chemical processing, power generation, and logistics, downtime directly impacts profitability. High-availability PLCs mitigate unplanned shutdowns by diagnosing faults in real time and shifting operations to backup systems. With modules like the BMEH584040S, the system detects issues before they cause failures, ensuring smooth performance around the clock.

Enhancing Safety and Compliance

Safety is a top priority in industrial environments. High-availability PLC systems help ensure that safety protocols and interlocks function consistently. They support emergency shutdown procedures, hazard monitoring, and safe operational sequences. When paired with accurate energy-monitoring devices such as the METSEPM5111, plants can also maintain safer power conditions by analyzing loads, detecting anomalies, and preventing electrical failures.

Improved Diagnostics and Predictive Maintenance

Modern PLC systems generate detailed diagnostics that engineers use to schedule maintenance before failures occur. This reduces unexpected downtime and extends the lifespan of industrial equipment.

Real-Time Data for Smarter Decisions

High-availability PLC modules continuously monitor system health, performance, and communication. Components like BMEH584040S enable faster processing of diagnostic data, making it easier for engineers to identify inefficiencies. When combined with power quality analysis using tools like METSEPM5111, operators can optimize energy usage and reduce operational costs.

Predictive Maintenance for Reduced Costs

Predictive maintenance relies heavily on accurate, real-time data. By using high-availability PLCs and energy-monitoring devices, plants can predict equipment failure patterns, schedule repairs proactively, and avoid expensive breakdowns. This not only reduces maintenance costs but also increases plant reliability and efficiency.

Supporting Scalability and Future Growth

Industrial plants constantly evolve, requiring scalable systems that can grow with their needs.

Modular Architecture for Easy Expansion

High-availability PLC systems are built with modularity in mind. This allows plants to add new processing modules, advanced input/output units, or high-performance devices like BMEH584040S without shutting down operations. The flexibility to expand without downtime is a major advantage for industries expecting long-term growth.

Energy Monitoring for Efficient Growth

As plants expand, so does their energy demand. Monitoring devices like METSEPM5111 offer detailed insights into power usage, helping plants plan for expansion without overloading systems. The data collected can guide decisions on equipment upgrades, infrastructure scaling, and power management strategies.

Boosting Energy Efficiency and Sustainability

Energy efficiency has become a significant focus for modern industrial plants aiming to reduce operational costs and environmental impact.

Monitoring Energy Flow with Advanced Tools

High-availability PLC systems can integrate with energy analysis devices to provide a holistic view of a plant’s power consumption. Devices such as METSEPM5111 help operators track energy use, identify inefficiencies, and manage peak loads. This integration allows plants to reduce energy waste and improve sustainability.

Supporting Green Manufacturing Initiatives

By maintaining consistent operations and reducing energy wastage, high-availability PLC systems directly contribute to sustainability goals. They help industrial plants meet environmental standards and support long-term energy reduction strategies.

Ensuring Reliable Communication Across Industrial Networks

Industrial networks rely on uninterrupted data exchange to synchronize machinery, sensors, and control systems.

Redundant Communication Paths

High-availability PLC architectures include redundant communication channels that prevent data loss during network failures. Components like BMEH584040S support advanced communication protocols that enhance network reliability. This ensures seamless data flow throughout the plant, from automation lines to central monitoring systems.

Improved Network Visibility

With integrated monitoring devices such as METSEPM5111, operators can track energy-related communication data as well, helping teams understand how power fluctuations affect network performance.

Conclusion

High-availability PLC systems are essential for modern industrial plants aiming for continuous production, enhanced safety, and efficient operation. By integrating powerful processing modules like BMEH584040S and energy-monitoring devices such as METSEPM5111, plants can achieve higher reliability, smarter diagnostics, optimized energy use, and stronger resilience against failures. As industries evolve and demand grows, high-availability PLC systems will continue to play a crucial role in ensuring smooth, safe, and sustainable industrial operations.