A Complete Guide to the GE Fanuc Relay Module

A Complete Guide to the Relay Module

Relay modules play an essential role in modern automation, electrical control systems, and industrial machinery. They provide the crucial connection between low-power control signals and high-power loads, making operations safer, smoother, and more efficient. This complete guide explains how relay modules work, their components, applications, installation practices, advantages, and why they remain a key part of today’s control systems.

What Is a Relay Module?

A relay module is an electrically operated switching device used to control a high-voltage or high-current circuit through a low-voltage signal. It ensures electrical isolation between the control side and the load side, protecting delicate control equipment from voltage spikes, overloads, and electrical faults.

Relay modules are commonly seen in automation panels, industrial machines, home automation systems, power distribution, and electronics projects.

How a Relay Module Works

Relay modules operate based on electromagnetic principles. When a low-voltage signal energizes the coil, it generates a magnetic field that activates a switching mechanism connected to the load.

Coil Operation

The coil generates the magnetic force needed to move the internal switching armature. Without the coil, the relay would not respond to the control signal.

Contact Switching

Contacts determine how the connected device is controlled. These can include:

- Normally Open (NO)

- Normally Closed (NC)

- Changeover contacts

Each type serves different switching needs.

Electrical Isolation

One major advantage is the complete electrical separation between the low-voltage control side and the high-voltage load. This prevents damage to control equipment.

Components of a Relay Module

Relay modules contain several internal parts that work together to ensure proper switching and safe operation.

Coil

Receives the control voltage and produces a magnetic field.

Armature

A metal lever that moves when the coil is energized, causing the switching action.

Contacts

Metallic terminals that open or close the circuit connected to the external load.

Spring Mechanism

Returns the armature to its original position when the control signal stops.

Protective Housing

Provides insulation and protection from dust, vibration, and external damage.

Terminal Blocks

Allow safe wiring connections for both control inputs and load outputs.

Types of Relay Modules

Relay modules come in several designs based on switching mechanism, speed, and usage.

Electromechanical Relay Modules

Use physical movement for switching. They offer strong load capacity and excellent electrical isolation.

Solid-State Relay Modules

Use electronic components instead of moving parts. These provide:

- Faster switching

- Silent operation

- Longer service life

Single-Channel Relay Modules

Designed to control one load at a time.

Multi-Channel Relay Modules

Usually available in 2, 4, 8, or 16 channels. Perfect for systems that need multiple devices controlled from one unit.

How Relay Modules Improve Automation

Relay modules are vital for automation due to their ability to interface high-power equipment with low-voltage control systems.

Reliable Load Switching

They manage motors, heaters, solenoids, pumps, and large machinery without stressing the control device.

Protection for Control Systems

Isolation protects sensitive parts like PLCs, sensors, circuit boards, and microcontrollers.

Wide Compatibility

Relay modules can handle AC and DC loads of various voltage levels.

Applications of Relay Modules

Relay modules are used across many industries and control systems.

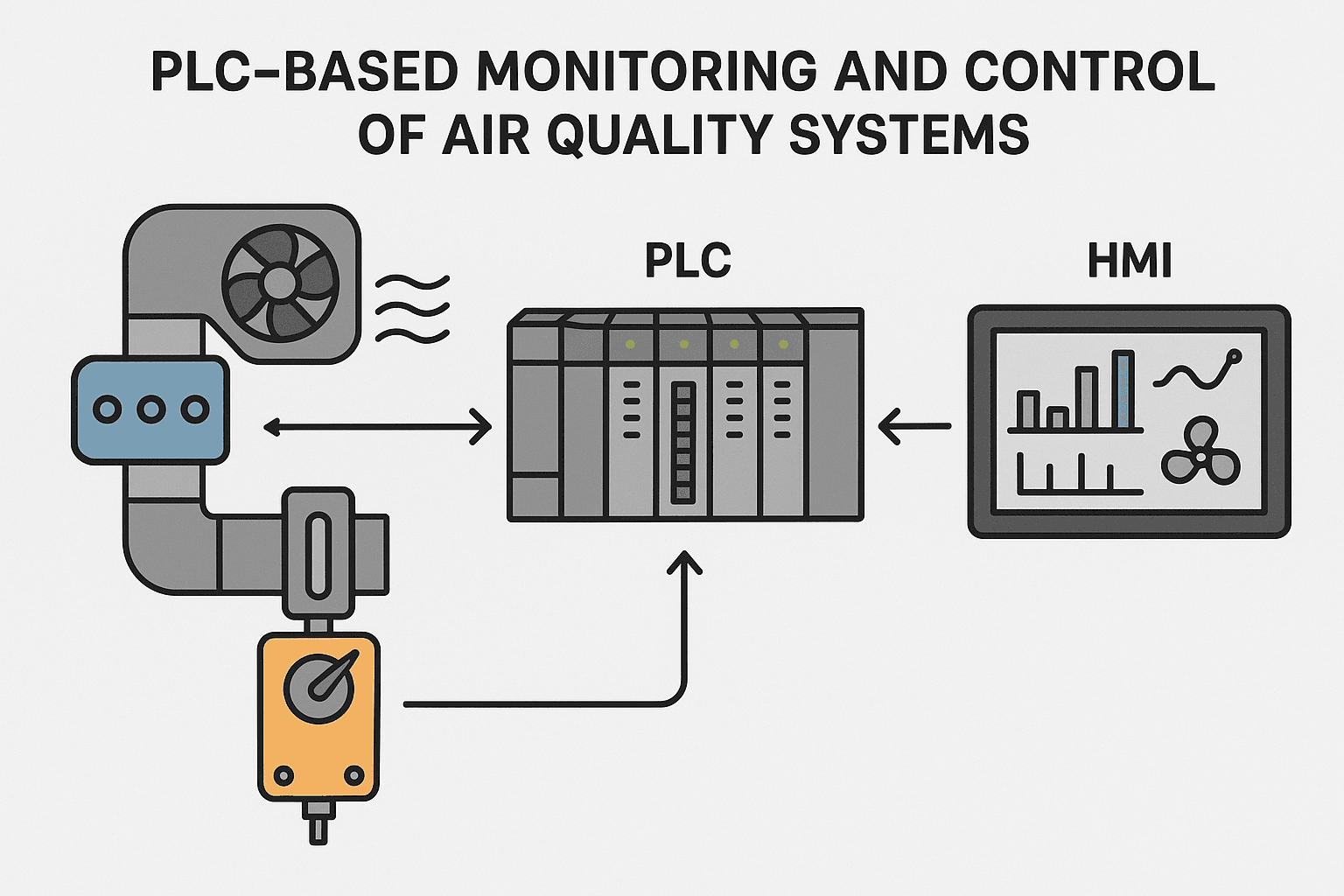

Industrial Automation

Control conveyors, robotic arms, pumps, assembly lines, and packaging machines.

Building Management

Used in HVAC systems, lighting control, access systems, and energy management.

Home Automation

Control lights, fans, appliances, and smart switches.

Automotive Systems

Used for lighting, climate control, power windows, and dashboard systems.

Power Distribution

Regulate load control in commercial and industrial power panels.

Water Pumping Systems

Control irrigation systems, pump motors, and water management units.

Advantages of Relay Modules

Relay modules provide multiple benefits that make them essential in electrical design and automation.

Electrical Isolation

Protects control circuits from high voltages and spikes.

High Current Capacity

Handles heavy loads without overheating.

Voltage Flexibility

Compatible with different AC and DC voltage levels.

Durability

Mechanical relays can operate for millions of cycles when properly maintained.

Cost-Effectiveness

Affordable compared to other switching technologies while providing strong performance.

Installation and Wiring Guidelines

Correct installation ensures long-lasting, safe, and reliable operation.

Match Power Ratings

Ensure the relay’s voltage and current specifications match the load.

Tight and Clean Wiring

Loose connections can cause sparking, heating, or system failure.

Maintain Isolation

Keep control wiring separate from high-power wiring.

Use Protective Devices

Install surge protectors, fuses, or circuit breakers for additional safety.

Test the Module

Conduct initial testing before full-scale operation.

Common Problems and Troubleshooting

Relay modules are reliable, but occasional issues can occur.

Relay Not Activating

Caused by:

- Incorrect coil voltage

- Damaged wiring

- Faulty control signal

Overheating

Happens due to overload, loose wiring, or insufficient ventilation.

Worn Contacts

Over time, mechanical contacts may wear out, especially with inductive loads.

Noise or Vibration Issues

External vibrations may interfere with relay performance.

How to Choose the Right Relay Module

Selecting the correct relay module depends on application needs.

Determine Load Type

Know whether the load is AC, DC, resistive, or inductive.

Check Voltage and Current Ratings

Choose a relay capable of safely handling the load.

Select Number of Channels

Based on how many circuits you want to control.

Switching Speed Requirement

Solid-state relays are better for fast switching tasks.

Consider the Environment

Temperature, humidity, and dust can affect performance; choose modules with protective designs.

The Role of Relay Modules in Modern Control Systems

Relay modules remain essential in electrical and automation systems. Their ability to safely switch high-power loads, provide electrical isolation, and integrate with low-voltage control logic makes them indispensable.

From industrial automation to residential systems, they ensure dependable performance, longevity, and operational efficiency.

Conclusion

Relay modules are fundamental to controlling electrical devices in automation, power distribution, home systems, and industrial applications. Their reliable switching, safety features, and compatibility with various load types make them vital for modern control environments.

This complete guide has detailed how relay modules work, their types, components, applications, troubleshooting, and installation. Understanding these aspects helps engineers, technicians, and system designers select the right module and ensure safe operation.