Future Ready Interface Accessories For Demanding Industrial Control Applications

Industrial control environments are evolving rapidly as systems become more connected, data-driven, and performance-sensitive. Operators now expect faster response times, higher reliability, and seamless integration between hardware and software components. In this landscape, interface accessories play a critical role in ensuring control systems remain flexible, scalable, and ready for future demands, with solutions such as XBTZG925 Adaptor for Terminal XBT for Advanced Panel enabling stable and efficient connectivity within advanced operator interfaces. From improving communication between panels and controllers to supporting reliable data storage, modern interface accessories are no longer optional add-ons. They are essential components that help industrial operations maintain efficiency, continuity, and long-term adaptability.

The Growing Importance Of Interface Accessories In Industrial Systems

As industrial automation grows more complex, the connections between system components become just as important as the core controllers themselves.

Supporting System Integration

Interface accessories enable different parts of an industrial system to communicate effectively. They bridge gaps between displays, control units, and storage devices, ensuring smooth data exchange and coordinated operation.

Adapting To Changing Requirements

Future-ready accessories allow systems to evolve without complete redesigns. This adaptability reduces upgrade costs and minimizes operational disruption when new capabilities are introduced.

Interface Adaptors And Panel Connectivity

Operator panels are the primary point of interaction between humans and machines. The accessories that support these panels directly influence usability and performance.

Enabling Seamless Panel Integration

Solutions such as XBTZG925 Adaptor for Terminal XBT for Advanced Panel highlight the importance of reliable interface adaptors. These components ensure secure physical and electrical connections, allowing panels to function efficiently within complex control architectures.

Benefits Of High-Quality Panel Adaptors

- Stable and consistent signal transmission

- Reduced installation complexity

- Improved durability in harsh environments

- Enhanced compatibility across system components

By ensuring dependable connections, adaptors help prevent communication failures that could otherwise lead to downtime.

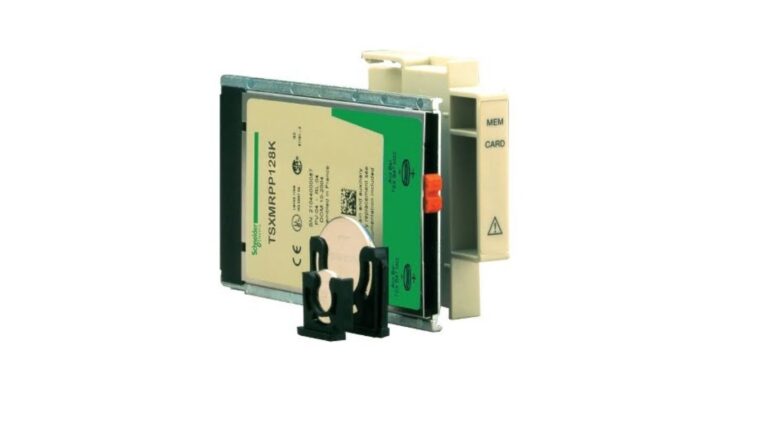

Data Storage Accessories In Modern Control Applications

Data plays a vital role in today’s industrial environments, supporting diagnostics, performance optimization, and regulatory compliance.

The Role Of Removable Memory Solutions

Accessories like BMXRMS008MPF SD flash memory card 8 Mb demonstrate how compact storage solutions support operational efficiency. These memory cards allow systems to store logs, configuration data, and application files reliably.

Advantages Of Dedicated Industrial Storage

- Secure retention of critical system data

- Faster system recovery after faults

- Simplified backup and restoration processes

- Support for long-term data analysis

Reliable storage accessories help ensure that valuable operational data is always accessible when needed.

Reliability In Demanding Industrial Conditions

Industrial environments often expose equipment to extreme temperatures, vibration, dust, and electrical noise. Interface accessories must be designed to withstand these conditions.

Designing For Harsh Environments

Future-ready accessories use robust materials and precise engineering to maintain performance under stress. This reliability reduces maintenance requirements and extends overall system lifespan.

Minimizing Failure Points

High-quality interface components reduce the likelihood of loose connections, data corruption, or signal loss. Fewer failures mean fewer interruptions and more consistent production.

Supporting Modular And Scalable Architectures

Modern control systems increasingly rely on modular designs. Interface accessories are essential to making this approach effective.

Simplifying Expansion And Upgrades

With the right accessories in place, new panels, memory devices, or communication paths can be added without major system changes. This modularity allows facilities to scale operations as demand grows.

Reducing Upgrade Downtime

Future-ready accessories support plug-and-play functionality, enabling faster installation and reducing downtime during system enhancements.

Enhancing Operational Efficiency Through Better Interfaces

Efficiency is not only about speed—it is also about accuracy, clarity, and ease of use.

Improved Operator Interaction

Reliable panel connections ensure that operators receive accurate, real-time information. This clarity supports faster decision-making and reduces the risk of human error.

Streamlined Maintenance Processes

Accessible storage accessories simplify software updates, diagnostics, and configuration management. Maintenance teams can work more efficiently with less system disruption.

Data Security And System Integrity

As industrial systems handle increasing volumes of data, protecting that data becomes a priority.

Secure Data Handling

Dedicated memory accessories help ensure that sensitive operational data is stored securely and protected from corruption.

Consistent System Behavior

Stable interfaces contribute to predictable system performance. Consistency builds trust in the control system and reduces the need for manual intervention.

Preparing For Future Technological Demands

Future-ready interface accessories are designed with long-term usability in mind.

Compatibility With Emerging Technologies

Accessories that support standardized connections and flexible configurations are better suited to integrate with future technologies, including advanced analytics and remote monitoring tools.

Long-Term Cost Savings

Investing in adaptable accessories reduces the need for frequent replacements. Over time, this lowers total cost of ownership and supports sustainable system growth.

Best Practices For Selecting Interface Accessories

Choosing the right interface components requires careful consideration of both current and future needs.

Evaluate Environmental Conditions

Accessories should be rated for the specific environmental challenges of the application, including temperature and vibration.

Prioritize Compatibility And Quality

Ensuring compatibility with existing equipment and selecting high-quality components minimizes integration risks and maintenance costs.

Conclusion

Future-ready interface accessories are foundational to the success of demanding industrial control applications. By supporting reliable connectivity, secure data storage, and modular system design, these components help industrial operations remain resilient and adaptable.

Solutions such as XBTZG925 Adaptor for Terminal XBT for Advanced Panel and BMXRMS008MPF SD flash memory card 8 Mb illustrate how thoughtfully designed accessories enhance system performance, reliability, and scalability. As industrial environments continue to evolve, investing in robust and flexible interface accessories will be key to maintaining efficiency, minimizing downtime, and preparing for the technologies of tomorrow.