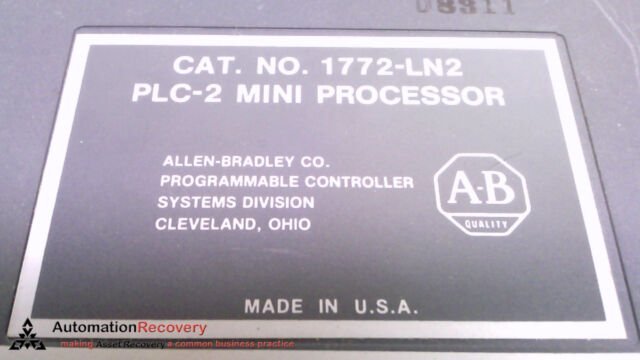

1772LN2 Allen-Bradley

Original price was: $975.00.$750.00Current price is: $750.00.

3 in stock

Free shipping on orders over $5000!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

Technical Specifications for 1772-LN2

| Manufacturer | Rockwell Automation |

| Brand | Allen-Bradley |

| Part Number/Catalog No. | 1772-LN2 |

| Module Type | Mini Processor |

| Max Number of I/O | 32 I/O |

| Number of Terminals | 40 Terminals |

| Max Fuse Size | N/A |

| Contact Plating | Tin |

| Screw Torque | 7-9 lb*in |

| Listing | These specifications were compiled by DO Supply and are only for DO Supply’s use. |

| Typical Application | 10-32 Volts DC, Digital |

| Weight | 0.3 lbs (0.1 kg) |

| Coating | Conformal Coat |

| Required External Power | None |

| Typical AC Signal Delay (Off) | 29 (+/- 8) ms |

| Typical DC Signal Delay (Off) | 30 (+/- 7) ms |

| Wiring Arm | 1771-WN |

| Dimensions | 4.5 x 12.4 x 6.3 in. (115 x 317 x 160 mm) |