ATV32HU22N4 Schneider Electric

$831.00 Original price was: $831.00.$625.00Current price is: $625.00.

25 in stock

Free shipping on orders over $5000!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

| Range of Product | Altivar 32. |

|---|---|

| Product or Component Type | Variable speed drive.. |

| Product destination | Synchronous motors.. Asynchronous motors. |

| Product Specific Application | Complex machines.. |

| function available | – |

| Assembly style | With a heat sink. |

| Component name | ATV32 |

| EMC filter | Class C2 EMC filter integrated. |

| Phase | 3 phase. |

| [Us] rated supply voltage | 380…500 V = 15…10%. |

| Supply voltage limits | 323…550 V.. |

| Supply frequency | 50…60 Hz – 5…5 %. |

| Network Frequency | 47.5…63 Hz. |

| Motor power kW | 2.2 kW, 380–480 V. |

| Maximum Horse Power Rating | 3 hp, 380…480 V. |

| Line current | 6.6 A, 500 V, 3 phase, 2.2 kW, / 3 hp. 8.7 A, 380 V, 3 phase, 2.2 kW, / 3 hp. |

|---|---|

| Apparent power | 5.7 kVA, 500 V, 3 phase, 2.2 kW, / 3 hp. |

| Prospective line Isc | 5 kA, 3 phases. |

| Nominal output current | 5.5 A, 4 kHz, 500 V, 2.2 kW, / 3 hp. |

| Maximum transient current | 8.3 A 60 s 2.2 kW/3 hp. |

| Output frequency | 0.0005…0.599 kHz. |

| Nominal switching frequency | 4 kHz |

| Switching frequency | 2–16 kHz adjustable. |

| Speed range | 1…100 asynchronous motor in open-loop mode. |

| Speed accuracy | +/- 10% of nominal slip 0.2 Tn to Tn. |

| Torque accuracy | +/- 15%. |

| Transient overtorque | 170…200 % |

| Braking torque | <= 170% with the braking resistor. |

| Asynchronous motor control profile | Voltage/frequency ratio: energy savings, quadratic U/F. Flux vector control without sensor, standard. Voltage/frequency ratio: 5 points. Flux vector control without a sensor is energy-saving. NoLoad law. Voltage/frequency ratio: 2 points. |

| Synchronous motor control profile | Vector control without a sensor. |

| Regulation loop | Adjustable PID regulator. |

| Motor slip compensation | Adjustable 0…300%. Not available in voltage/frequency ratio (2 or 5 points). Automatic, whatever the load. |

| Local signalling | 1 LED red drive voltage. 1 LED green CANopen run. 1 LED red CANopen error. 1 LED red drive fault. |

| Output voltage | <power supply voltage. |

| Noise level | 43 dB, 86/188/EEC. |

| insulation | Electrical between power and control. |

| Electrical connection | Screw terminal 0.5…1.5 mm², AWG 18…AWG 14 control) Removable screw terminals 1.5–2.5 mm2, AWG. 14–AWG 12 (motor/braking resistor). Screw terminal 1.5–4 mm2, AWG 14–AWG 10 power supply. |

| Tightening torque | 4.43 lbf.in. (0.5 N.m.), 4.4 lb/ft. control). 6.20 lbf.in. (0.7 N.m.), 7.1 lb/ft. motor/braking resistor). 5.31 lbf.in. (0.6 N.m.), 5.3 lb/ft. power supply). |

| Supply | Internal supply for reference potentiometer (1 to 10 kOhm): 10.5 V DC +/- 5%, <10 mA overload, and short-circuit protection. |

| Analogue input number | 3 |

| Analogue input type | AI1 voltage: 0…10 V DC, 30000 Ohm, 10 bits. AI2 bipolar differential voltage +/- 10 V DC 30000 Ohm 10 bits. AI3 current: 0…20 mA (or 4-20 mA, x-20 mA, 20-x mA, or other patterns by configuration): 250 Ohm, 10 bits. |

| Sampling duration | 2 ms (AI1, AI2, AI3)—analog. 2 ms AO1): analog. |

| Response time | LI1…LI6: 8 ms +/- 0.7 ms logic. R1A, R1B, and R1C 2 ms relay. R2A, R2C, 2 ms relay. |

| Accuracy | +/- 0.2 % AI1, AI2, AI3) for a temperature of -10…60 °C. +/- 0.5% AI1, AI2, AI3) for a temperature of 25 °C. +/- 1% AO1) for a temperature of 25 °C. +/- 2% AO1) for a temperature of -10.60 °C. |

| Linearity error | +/- 0.2–0.5% of the maximum value (AI1, AI2, AI3). +/- 0.3% AO1). |

| Analogue output number | 1 |

| Analogue output type | AO1 software-configurable current 0…20 mA, 800 Ohm, 10 bits. AO1 software-configurable voltage: 0…10 V, 470 Ohm, 10 bits. |

| Discrete output number | 3 |

| Discrete output type | Configurable relay logic (R1A, R1B, and R1C): NO/NC: 100000 cycles. Configurable relay logic R2A, R2B) NO – 100000 cycles Logic LO). |

| Minimum switching current | 5 mA, 24 V DC, configurable relay logic. |

| Maximum switching current | R1 3 A 250 V AC resistive, cos phi = 1. R1 4 A 30 V DC resistive, cos phi = 1. R1, R2 2 A 250 V AC inductive, cos phi = 0.4. R1, R2 2 A 30 V DC inductive, cos phi = 0.4. R2 5 A 250 V AC resistive, cos phi = 1. R2 5 A 30 V DC resistive, cos phi = 1. |

| Discrete input number | 7 |

| Discrete input type | Programmable (sink/source) LI1… LI4 24… 30 V DC level 1 PLC. Programmable as a pulse input of 20 kpps (Li5) at 24–30 V DC level 1 PLC. Switch-configurable PTC probe LI6) 24–30 V DC. Safe torque off STO: 24–30 V DC, 1500 Ohm. |

| Discrete input logic | Negative logic (sink) LI1… LI6), > 19 V, < 13 V. Positive logic (source): LI1… LI6), < 5 V, > 11 V. |

| Acceleration and deceleration ramps | S. CUS. Linear.. Deceleration ramp adaptation. Ramp switching. Deceleration ramp automatic stop DC injection. U. |

| Braking to standstill | By DC injection. |

| Protection type | The input phase breaks the drive. Overcurrent between output phases and earth drive. Overheating protection drive. Short-circuit between motor phases drives. Thermal protection drive. |

| communication port protocol | Modbus. CANopen. |

| Connector type | 1 RJ45 on front face)Modbus/CANopen. |

| Physical interface | 2-wire RS 485 Modbus. |

| Transmission frame | RTU Modbus. |

| Types of polarization | No impedance Modbus. |

| Number of addresses | 1…127 CANopen. 1…247 Modbus. |

| Method of access | Slave CANopen. |

| Electromagnetic compatibility | 1.2/50 µs–8/20 µs surge immunity test, level 3 IEC 61000-4-5. Conducted a radio-frequency immunity test, level 3 IEC 61000-4-6. Electrical fast transient/burst immunity test, level 4 IEC 61000-4-4. Electrostatic discharge immunity test, level 3, IEC 61000-4-2. Radiated radio-frequency electromagnetic field immunity test, level 3, IEC 61000-4-3. Voltage dips and interruptions immunity test (IEC 61000-4-11). |

| Width | 2.36 in. (60 mm). |

| Height | 12.80 in (325 mm). |

| Depth | 9.65 in (245 mm). |

| Net Weight | 6.61 lb (US) (3 kg). |

| Option card | Communication card: CANopen daisy chain. Communication card CANopen open style. Communication card: DeviceNet. Communication card: EtherNet/IP. Communication card Profibus DP V1. |

| Functionality | Mid. |

| Specific application | Other applications. |

| Standards | EN 55011, class A, group 1. EN/IEC 61800-3. EN 61800-3 Environments, Category C2 EN/IEC 61800-5-1. EN 61800-3 environments 2 category C2. |

|---|---|

| Product Certifications | UL. CSA. GOST. NOM 117. C-tick. |

| Marking | CE. |

| Pollution degree | 2 EN/IEC 61800-5-1. |

| IP degree of protection | IP20 EN/IEC 61800-5-1. |

| Vibration resistance | 1 gn (13…200 Hz) EN/IEC 60068-2-6. 1.5 mm peak to peak (3…13 Hz) EN/IEC 60068-2-6. |

| Shock resistance | 15 gn 11 msEN/IEC 60068-2-27. |

| Relative humidity | 5…95 % without condensation IEC 60068-2-3. 5… 95%% without dripping water IEC 60068-2-3. |

| Ambient air temperature for operation | 14…122 °F (-10…50 °C) without derating. 122…140 °F (50…60 °C) with derating factor. |

| Ambient Air Temperature for Storage | -13…158 °F (-25…70 °C). |

| Operating altitude | <= 3280.84 ft (1000 m) without derating 3280.84…9842.52 ft (1000…3000 m) with current derating 1 % per 100 m. |

| Operating position | Vertical +/- 10 degree. |

| Category | 22152-ATV320/ATV312/ATV32 (.25 THRU 7.5HP). |

|---|---|

| Discount Schedule | CP4B. |

| GTIN | 00785901687634. |

| Returnability | No |

| Country of origin | ID |

Related products

-

Sale!

3503E Digital Input Module Triconex

$1,651.00Original price was: $1,651.00.$1,170.00Current price is: $1,170.00. -

Sale!

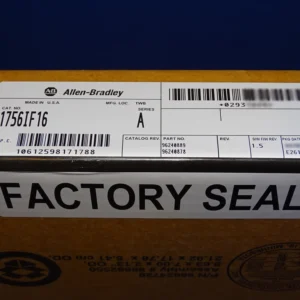

Allen-Bradley 1756-IF8H/A

$5,460.00Original price was: $5,460.00.$4,500.00Current price is: $4,500.00. -

Sale!

1756-IF16A Allen-Bradley

$2,405.00Original price was: $2,405.00.$1,850.00Current price is: $1,850.00. -

Sale!

SIEMENS 6ES7138-4CA50-0AB0

$40.00Original price was: $40.00.$30.00Current price is: $30.00.