Industrial Automation with PLCs

Introduction

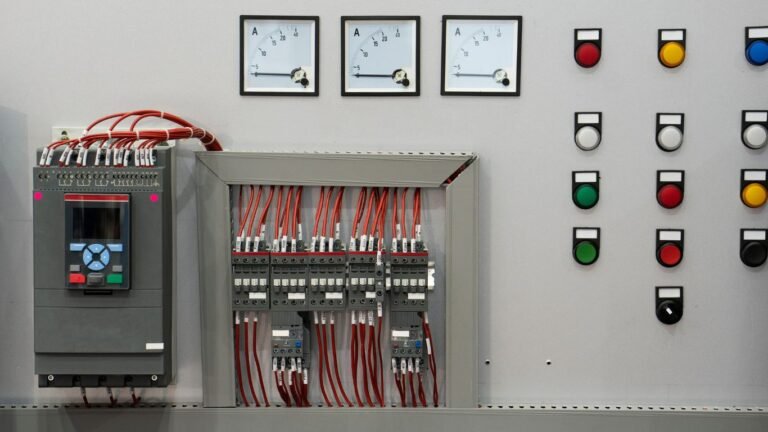

In the realm of industrial automation, Programmable Logic Controllers (PLCs) stand as the backbone of modern manufacturing processes. These versatile devices have revolutionized the way industries operate, bringing efficiency, flexibility, enhanced industrial automation and reliability to the forefront. In this article, we will explore how PLCs contribute to making significant improvements in industrial automation. This is an excellent tool for enhancing industrial automation.

- Flexibility and Adaptability

One of the key advantages of PLCs is their ability to adapt to changing manufacturing requirements. Traditional control systems often involve complex and rigid wiring, making modifications a time-consuming and costly endeavor. PLCs, on the other hand, offer a high degree of flexibility. Their programmable nature allows for swift alterations in control logic, facilitating quick adjustments to accommodate changes in production processes or product specifications.

For instance, in a manufacturing setup where product variations are common, PLCs can easily handle different parameters and sequences by simply reprogramming the controller. This adaptability reduces downtime associated with reconfiguration, enabling industries to respond promptly to market demands and changes in production requirements.

- Enhanced Control and Precision

PLCs excel in providing precise control over industrial processes. Their ability to execute complex sequences of operations with high accuracy ensures consistent product quality. PLCs can monitor and control variables such as temperature, pressure, and flow rates with remarkable precision, leading to improved production efficiency and reduced waste.

In scenarios where tight control is critical, such as in chemical manufacturing or food processing, PLCs play a pivotal role in maintaining optimal conditions. This level of precision enhances the overall quality of the end product and minimizes the likelihood of defects, thereby contributing to increased customer satisfaction.

- Integration with Other Systems

In the era of Industry 4.0, seamless integration of different components within a manufacturing system is paramount. PLCs serve as a bridge, connecting various devices and systems to create a cohesive and interconnected industrial environment. They can communicate with sensors, actuators, human-machine interfaces (HMIs), and other control systems, fostering a more integrated and intelligent automation ecosystem.

This integration capability extends beyond the confines of a single production line. PLCs can be linked to supervisory control and data acquisition (SCADA) systems, enterprise resource planning (ERP) systems, and other higher-level management systems. This connectivity enables real-time monitoring, data collection, and analysis, empowering decision-makers with valuable insights for optimizing overall operational efficiency.

- Fault Detection and Diagnostics

The robust diagnostic features of PLCs contribute significantly to reducing downtime and maintenance costs. PLCs can monitor the health of connected devices and systems in real-time, enabling the early detection of faults or anomalies. Advanced PLCs come equipped with self-diagnostic capabilities that can identify issues such as sensor malfunctions, communication errors, or equipment failures.

By promptly identifying and isolating faults, PLCs facilitate quick troubleshooting and maintenance interventions. This proactive approach minimizes unplanned downtime, increases the lifespan of industrial equipment, and ultimately contributes to a more reliable and efficient manufacturing process.

- Cost-Efficiency and Resource Optimization

PLCs offer a cost-effective solution for industrial automation. Their versatility and reprogrammable nature mean that a single PLC can replace multiple traditional control devices, reducing both hardware costs and the complexity of wiring. Moreover, the ability to make changes in software rather than hardware eliminates the need for extensive rewiring during modifications or upgrades.

Additionally, the energy efficiency features of many PLCs contribute to sustainable and cost-effective operations. PLCs can optimize energy usage by controlling equipment and processes based on demand, leading to reduced energy consumption and operational costs.

Conclusion

Programmable Logic Controllers have undoubtedly transformed industrial automation by providing a platform that combines flexibility, precision, integration, fault detection, and cost-efficiency. As industries continue to evolve and embrace advanced technologies, PLCs will play a pivotal role in shaping the future of manufacturing processes. The ability to adapt to changing requirements, seamlessly integrate with other systems, and enhance control and diagnostics make PLCs indispensable in the pursuit of efficient, reliable, and sustainable industrial automation.