Future Trends in PLC Technology: What to Expect

Introduction

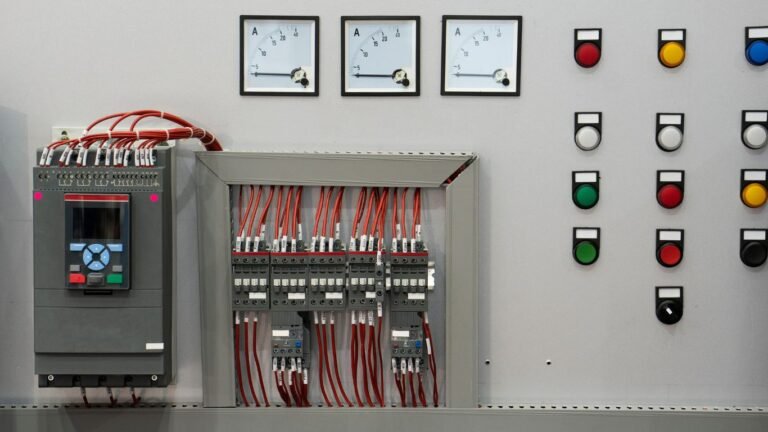

Programmable Logic Controllers (PLCs) have been pivotal in industrial automation, providing robust, reliable, and versatile control solutions for various applications. As we look toward the future, several emerging trends are poised to redefine the PLC landscape. This article explores the anticipated advancements in PLC technology and their potential impact on industries worldwide.

1. Integration with IoT and IIoT

The integration of Internet of Things (IoT) and Industrial Internet of Things (IIoT) with PLC systems is set to revolutionize industrial automation. IoT-enabled PLCs will offer enhanced data collection and real-time analytics, enabling more precise control and monitoring of industrial processes. The use of sensors and smart devices will provide PLCs with a wealth of data, facilitating predictive maintenance, optimizing performance, and improving operational efficiency.

Key Benefits:

- Real-time monitoring and data analytics for better decision-making.

- Enhanced predictive maintenance through data-driven insights.

- Increased efficiency and reduced downtime with proactive adjustments.

2. Edge Computing and Decentralization

Edge computing is gaining traction as it allows data processing to occur closer to the source, reducing latency and bandwidth requirements. In the context of PLCs, this means processing data locally rather than relying on centralized servers. Decentralized control systems are expected to become more prevalent, providing improved system responsiveness and reliability, particularly in environments with high data volumes and critical timing requirements.

Key Benefits:

- Reduced latency and improved response times.

- Lower bandwidth requirements and cost savings.

- Enhanced system reliability with localized data processing.

3. Enhanced Cybersecurity Measures

As PLC systems become increasingly interconnected, the need for robust cybersecurity measures grows. Future PLCs will likely incorporate advanced security protocols to protect against cyber threats. This includes encryption, secure authentication, and continuous monitoring for unusual activities. Cybersecurity will become a critical component of PLC design, ensuring the integrity and safety of industrial control systems.

Key Benefits:

- Increased protection against cyberattacks and data breaches.

- Enhanced system integrity with advanced security features.

- Compliance with industry regulations and standards.

4. Artificial Intelligence and Machine Learning

Artificial Intelligence (AI) and Machine Learning (ML) are set to play significant roles in the evolution of PLC technology. AI and ML algorithms can analyze vast amounts of data generated by PLCs to identify patterns, predict failures, and optimize processes. This integration will lead to more intelligent and adaptive control systems, capable of making autonomous decisions and learning from operational data.

Key Benefits:

- Enhanced decision-making through data-driven insights.

- Improved process optimization with adaptive control.

- Autonomous system adjustments and predictive maintenance.

5. Advanced Communication Protocols

The future of PLC technology will see the adoption of more advanced communication protocols. Emerging standards such as OPC UA (Open Platform Communications Unified Architecture) and the integration of 5G technology will enable faster and more reliable data exchange between PLCs and other system components. This will facilitate seamless integration with other industrial systems and support complex, data-intensive applications.

Key Benefits:

- Faster data transfer and improved communication.

- Seamless integration with other industrial systems.

- Support for complex applications with high data requirements.

6. Increased Use of Modular and Scalable Systems

Modular PLC systems, which allow for easy expansion and customization, will become more prevalent. These systems provide flexibility to adapt to changing needs and facilitate scaling as requirements evolve. Future PLC designs will emphasize modularity, enabling users to add or remove components as needed without overhauling the entire system.

Key Benefits:

- Flexibility to adapt to changing requirements.

- Ease of expansion and customization.

- Cost-effective scaling with modular components.

FAQs

Q: What is the role of IoT in PLC technology?

IoT enhances PLC systems by enabling real-time data collection and analysis, which leads to improved monitoring, predictive maintenance, and operational efficiency.

Q: How does edge computing benefit PLC systems?

Edge computing reduces latency and bandwidth requirements by processing data locally, which improves response times and system reliability.

Q: Why is cybersecurity important for PLCs?

As PLCs become more interconnected, robust cybersecurity measures are essential to protect against cyber threats and ensure the integrity of industrial control systems.

Q: What impact will AI and ML have on PLC technology?

AI and ML will enable PLC systems to analyze data, predict failures, and optimize processes, leading to more intelligent and adaptive control systems.

Q: How will advanced communication protocols affect PLC systems?

Advanced communication protocols will facilitate faster and more reliable data exchange, enabling seamless integration with other systems and supporting complex applications.

Q: What are the advantages of modular PLC systems?

Modular PLC systems offer flexibility, ease of expansion, and customization, allowing users to adapt and scale their systems according to evolving needs.

Conclusion

The future of PLC technology promises significant advancements driven by IoT integration, edge computing, enhanced cybersecurity, AI and ML, advanced communication protocols, and modular design. These trends will collectively enhance the capabilities of PLC systems, leading to more efficient, reliable, and intelligent industrial automation solutions. As industries continue to evolve, staying abreast of these trends will be crucial for leveraging the full potential of PLC technology.