High-Performance Industrial Controllers for Mission-Critical Automation

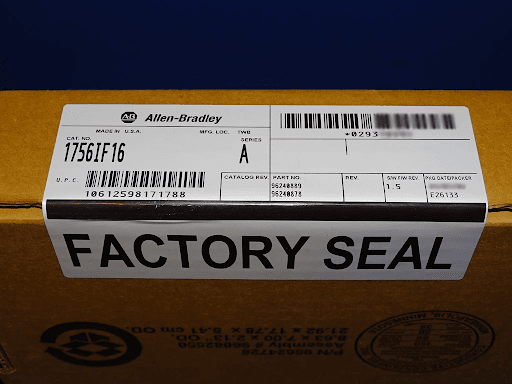

High-performance industrial controllers play a vital role in modern automation systems where reliability, speed, and accuracy are essential. In mission-critical environments such as manufacturing plants, energy systems, and process automation facilities, downtime is not an option. Solutions like 140CPU43412A Modicon Quantum and 140CPU67260 Modicon Quantum are often referenced in discussions about robust control architectures because they represent advanced processing capabilities required for complex industrial operations. These types of controllers are designed to handle demanding tasks while ensuring system stability and continuous performance.

Understanding Mission-Critical Automation Systems

Mission-critical automation refers to systems where failure can lead to serious operational, financial, or safety consequences. These systems must operate continuously under harsh conditions while managing complex processes.

Why Reliability Matters in Industrial Control

In industrial environments, controllers must function 24/7 without interruption. Even a short system failure can cause production losses or safety risks. High-performance controllers are built with fault-tolerant designs and stable processing architectures to meet these expectations.

The Role of Processing Power

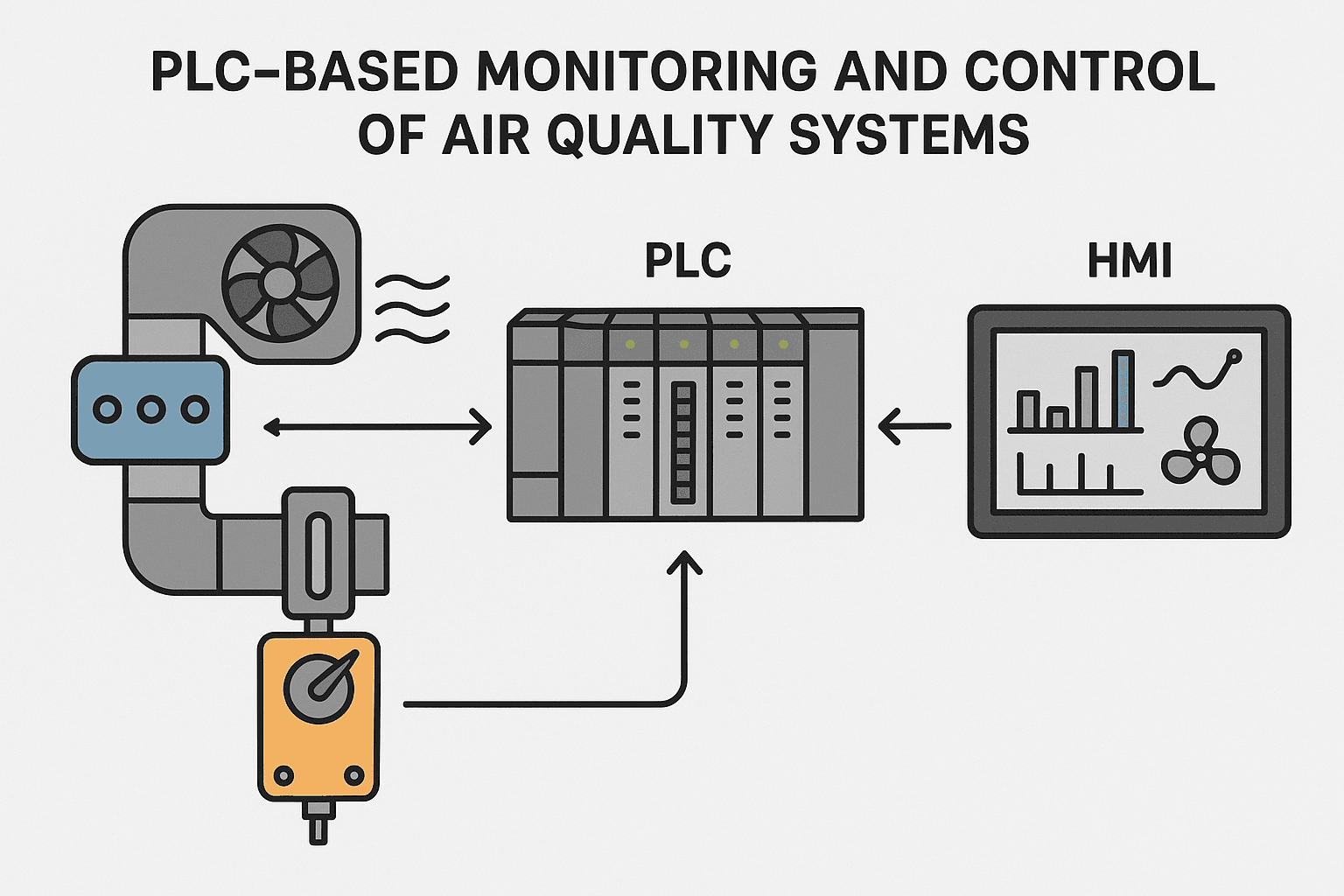

Advanced automation systems require controllers with strong processing capabilities. They must manage multiple inputs and outputs, execute control logic quickly, and communicate efficiently with other system components.

Key Features of High-Performance Industrial Controllers

Industrial controllers designed for mission-critical automation share several essential features that differentiate them from basic control systems.

High-Speed Data Processing

Fast data processing allows controllers to respond instantly to changing conditions. This is crucial in applications where timing and precision directly affect output quality and safety.

Large Memory Capacity

Controllers used in complex automation systems require sufficient memory to store control programs, system data, and communication parameters. This ensures smooth operation even as system demands increase.

Robust Communication Capabilities

Modern industrial controllers must support communication across multiple networks and devices. Reliable data exchange ensures coordination between different parts of the automation system.

Scalability for Complex Industrial Environments

As industrial operations grow, automation systems must scale accordingly. High-performance controllers are designed to support system expansion without compromising performance.

Modular System Design

A modular architecture allows new components to be added easily. This flexibility is especially important in facilities that continuously upgrade or expand production lines.

Integration With Existing Infrastructure

Scalable controllers can be integrated into existing automation setups, reducing the need for complete system replacements and minimizing downtime.

Applications of High-Performance Controllers

Industrial controllers are used across a wide range of mission-critical applications where precision and reliability are essential.

Manufacturing and Assembly Lines

In manufacturing, controllers manage robotic systems, conveyor belts, and quality control processes. High-performance control ensures consistent output and reduces errors.

Energy and Utilities

Power generation and distribution systems depend on automation to maintain stability. Controllers must handle real-time monitoring and control to prevent system failures.

Process Automation

Industries such as chemical processing and water treatment rely on precise control of variables like temperature, pressure, and flow. Reliable controllers ensure safe and efficient operations.

System Redundancy and Fault Tolerance

Mission-critical automation systems must be designed to handle unexpected failures without shutting down operations.

Redundant Processing Units

High-performance controllers often support redundant configurations. If one unit fails, another takes over instantly, ensuring uninterrupted operation.

Error Detection and Diagnostics

Advanced diagnostic features help identify potential issues before they become critical. This allows maintenance teams to address problems proactively.

Maintenance and Long-Term Performance

The longevity of an automation system depends on proper maintenance and controller durability.

Easy Troubleshooting and Monitoring

Controllers with clear diagnostic tools simplify troubleshooting. Real-time monitoring helps operators detect performance issues early.

Designed for Harsh Environments

Industrial controllers are built to withstand temperature extremes, vibration, and electrical noise, making them suitable for demanding environments.

Cost Efficiency Over Time

While high-performance controllers may require a higher initial investment, they offer long-term cost benefits.

Reduced Downtime Costs

Reliable controllers minimize system failures, which significantly reduces downtime-related expenses.

Lower Maintenance Requirements

Durable design and advanced diagnostics reduce the frequency and cost of maintenance activities.

Future-Proof Automation Systems

Industrial automation continues to evolve with increasing demands for data integration and system intelligence.

Support for Advanced Automation Strategies

High-performance controllers can support advanced control strategies and system optimization, helping facilities remain competitive.

Adaptability to Industry Changes

Scalable and powerful controllers allow businesses to adapt to new processes, regulations, and production requirements without major system overhauls.

Final Thoughts

In mission-critical automation environments, choosing the right control solution is essential for long-term success. High-performance industrial controllers provide the processing power, reliability, and scalability needed to manage complex operations. References such as 140CPU43412A Modicon Quantum and 140CPU67260 Modicon Quantum are commonly associated with discussions on advanced control capabilities because they reflect the level of performance required in demanding industrial systems. Investing in such robust control solutions ensures stable operations, improved efficiency, and long-term automation reliability.