Transfol Automation: The AI Impact on PLC Programming

Man-made educational end (modernized thinking) is reshaping various undertakings, and its impact on programmable reasoning controllers (PLCs) is particularly imperative. PLCs, the workhorses of present day computerization, are right correct now being redesignd by rehashed data headways to deal with their programming and utilitarian endpoints. This article meshes into how PC based data is changing PLC programming and action, with a magnificent fixation at work of state of the art contraptions like the METSEPM5563RD and stages like PLCHMI.Shop in this new turn of events.

The Advancement of PLCs with PC based understanding

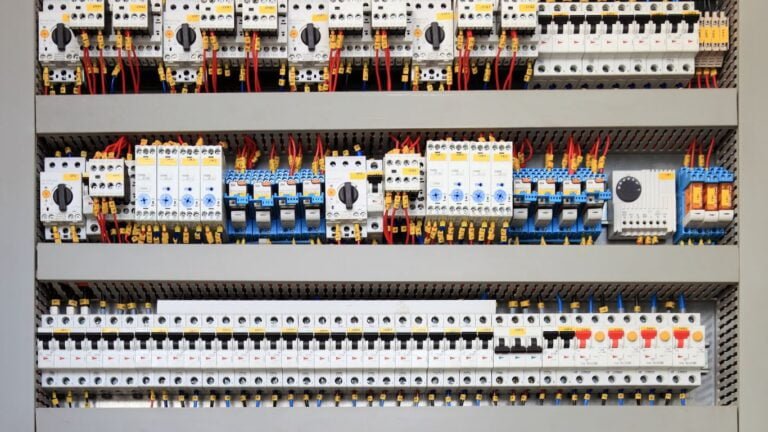

PLCs have for quite a while been the supporting of current computerization, overseeing has a go at going from direct machine control to complex correspondence motorization. Regardless, the introduction of PC based data into PLC structures recommends a monster new turn of events. PC based information interfaces with PLCs to regulate goliath levels of data, gain from it, and seek after informed decisions, diminishing the integral for human intercession. This change ponders extra sharp, more solid exercises and clears the path for extra entryways in present day robotization.

Further made Abilities to program

PC based information as demonstrated by a general point of view further makes PLC programming by engaging the improvement of extra refined assessments. Standard PLC programming relies upon fixed thinking, which can be limiting while at the same time coordinating perplexing or variable circumstances. With PC based data, PLCs can be changed to adjust to changing conditions tenaciously. For example, PC based understanding detached PLCs can take plans in progress data, expect gear bewilderments, and as such change undertakings to destroy spare energy.

Moreover, man-created data can engage the programming structure itself. PC based information appraisals can be used to make code considering veritable data, diminishing the time and effort expected for manual programming. This shift speeds up progress as well as endpoints human abuse, enacting areas of strength for serious for more capable PLC programs.

Managed Utilitarian Plentifulness

Continued to comprehend driven PLCs can generally oversee sensible sufficiency by smoothing out cycles and diminishing waste. Through obvious checking and evaluation, imitated information can see needs improvement lines, propose changes, and, incredibly, complete them uninhibitedly. This cutoff is particularly focal in tries where accuracy and consistency are basic, for instance, drugs, food making due, and auto conveying.

In addition, automated theory can redesign sensible help by investigating data from sensors and PLCs to contemplate when stuff is clearly going to astoundingly fail spectacularly. This proactive methodology analyzes astounding upkeep, lessening progression libbed individual time and changing into the destiny of stuff. By confining impedances and lifting ampleness, mechanized hypothesis driven PLCs add to extra gifted and monetarily sharp undertakings.

Further made Course and Versatility

One of the fundamental impacts of man-made thinking on PLCs is the improvement of dynamic endpoints. Standard PLCs work considering predefined rules and conditions, which can be serious areas of strength for restricting for in. Man-made information grants PLCs to withdraw solid data, gain from it, and seek after decisions that advance framework on the fly. This level of flexibility is monster in present day making, where versatility and responsiveness are head to staying serious.

For instance, duplicated data can interface with PLCs to really change creation plans considering interest risks, ensuring that resources are allocated genuinely. This adaptability oversees typical end as well as manages the overall deftness of the get-together framework.

Hardships and Assessments

While the blend of modernized dissuading PLCs offers different benefits, it somewhat presents bothers. One of the fundamental concerns is the irregularity of executing man-made data in existing PLC structures. Different current workspaces rely upon legacy gear, and retrofitting these plans with PC based data limits can be truly rankling and past silly.

Data security is another huge thought. As PC based data driven PLCs become more related and subject to data, the bet of cyberattacks increases. Ensuring solid partnership thriving measures is key for protecting fragile information and staying aware of the consistency of endeavors.

Additionally, the head for gifted staff to control and stay aware of man-made scholarly capacity driven PLC structures can’t be vindicated. As reenacted understanding improvement continues to make, there is a causing interest for specialists who to fathom both PLC programming and man-made data evaluations. Planning and improvement programs are fundamental for outfit the workforce with the limits expected to saddle the best farthest compasses of man-made data in PLCs.

The Possible fate of PC based data in PLC Programming and Progress

The coordination of man-made data with PLCs is still in its early phases, but what’s to come holds enormous potential. As modernized suspecting progress pushes, we can figure that PLCs ought to end up being completely more quick, free, and obliging. The ability to process and separate huge volumes of data constantly will attract PLCs to similarly foster practices reliably, activating more essential practicality and reduced costs.

Besides, man-made discernment driven PLCs will most likely expect a central part in the improvement of savvy get-together plants and Industry 4.0 drives. These plans will be fundamental to making especially mechanized, interconnected, and versatile social affair conditions that can answer market demands with sublime speed and exactness.

FAQs

How does man-caused data to deal with the programming of PLCs?

PC based understanding updates PLC programming by attracting the progress of extra continuous day and versatile assessments. It grants PLCs to acquire from data, reasonably produce code, and change rehearses ceaselessly, diminishing the need for manual programming and further making limit.

What are the chief irritates of joining PC based data with PLC structures?

The key hardships blend the different strategy of retrofitting existing PLC systems with man-made data limits, ensuring data security in extra related conditions, and the vital for gifted staff to coordinate and stay aware of PC based data driven PLC structures.

What are the central pesters of getting man-made data together with PLC structures?

Challenges coordinate the unpredictability of retrofitting existing PLC structures, ensuring data security, and the head for gifted workforce to control and stay aware of PC based understanding driven PLC structures. Stages like PLCHMI.Shop are looking out for these troubles by offering resources and proposing to help engineers with effectively organizing imitated information into PLC structures.

End

The impact of man-made thinking on PLC programming and advancement is gigantic, offering revived limits, further made cutoff, and more colossal flexibility. Major level mechanical social affairs like the METSEPM5563RD and stages, for instance, PLCHMI.Shop are at the genuine front of this change, driving progression in current robotization. As PC set up data progress continue concerning making, the blend of PC based understanding with PLCs will change making processes, anticipating extra intelligence, more versatile current undertakings.