PLC-Based Monitoring and Control of Air Quality Systems

Maintaining optimal air quality in industrial, commercial, and residential environments has become a critical concern due to increasing pollution levels and growing awareness of health and safety regulations. Poor air quality impacts not only human health but also machinery, product quality, and overall workplace safety. To address these challenges, Programmable Logic Controllers (PLCs) have emerged as one of the most efficient and reliable solutions for monitoring and controlling air quality systems. These systems provide real-time data processing, automation, and intelligent control, ensuring consistent environmental quality and regulatory compliance.

This article delves deep into the role of PLCs in air quality management and highlights the integration of specific components such as the tsxp572634m and tsxrky12 in modern industrial and commercial air quality monitoring systems.

The Importance of Air Quality Monitoring

Air quality has a profound impact on health, comfort, and operational efficiency. In industrial settings, airborne pollutants such as dust, chemical fumes, volatile organic compounds (VOCs), and gases like carbon monoxide (CO) and carbon dioxide (CO2) pose serious risks to workers and equipment. Prolonged exposure to these contaminants can cause respiratory issues, fatigue, and other health problems. Moreover, particulates can interfere with sensitive machinery, resulting in increased maintenance costs and downtime.

To mitigate these risks, regulatory bodies such as the Environmental Protection Agency (EPA), Occupational Safety and Health Administration (OSHA), and standards like ISO 14001 have set stringent requirements for air quality monitoring and control. Real-time monitoring and responsive control systems are essential for adhering to these regulations and ensuring safe working conditions.

Introduction to PLCs in Environmental Systems

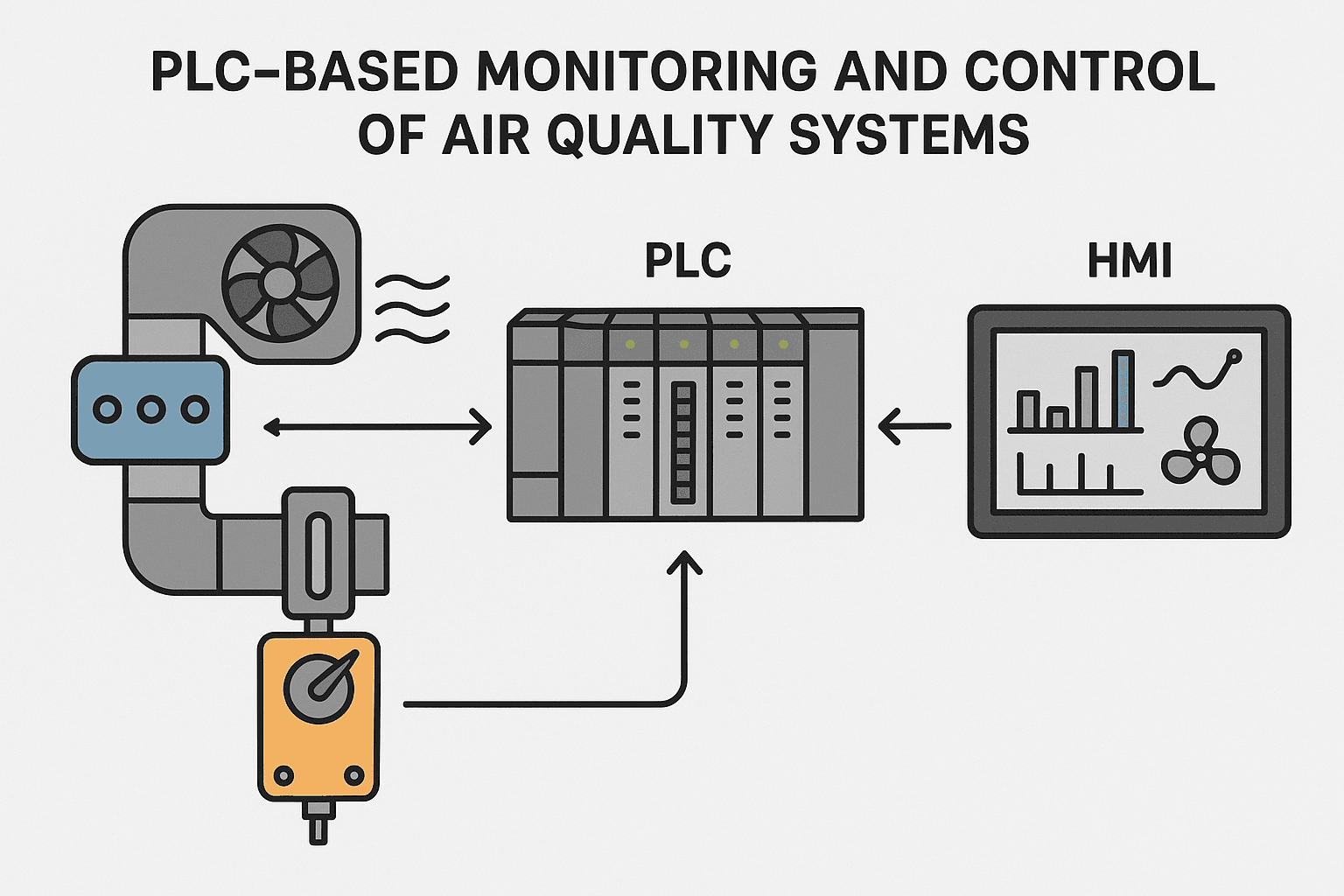

A Programmable Logic Controller (PLC) is a ruggedized digital computer designed to perform automation tasks in industrial environments. It reads input from various sensors, processes the data, and sends output signals to actuators and other devices to control systems like HVAC, filtration, and ventilation.

In air quality management, PLCs are used to collect and process data from a range of sensors that monitor parameters including:

- Temperature and humidity

- Carbon dioxide (CO2) and carbon monoxide (CO) levels

- Particulate matter (PM2.5 and PM10)

- Volatile organic compounds (VOCs)

- Airflow, pressure, and oxygen levels

By automating the control of ventilation systems, PLCs ensure that indoor air remains within predefined safe limits. This not only helps in maintaining regulatory compliance but also enhances energy efficiency and worker comfort.

Advantages of PLC-Based Air Quality Systems

PLC-based air quality systems offer numerous advantages over traditional control methods:

Automation and Precision

PLCs eliminate the need for manual monitoring and adjustment, reducing human error and enabling continuous, real-time operation. The system responds automatically to changes in air quality, ensuring optimal conditions are maintained.

Scalability and Flexibility

As operations grow or new pollutants need to be monitored, PLC systems can be easily expanded. Adding new sensors or control modules is straightforward, especially with modular systems like those based on the tsxrky12 rack.

Real-Time Monitoring and Reporting

Real-time data collection and processing allow for immediate response to hazardous air quality conditions. Alerts can be triggered, and corrective actions can be taken instantly.

Reliability in Harsh Environments

Designed for industrial use, PLCs can operate reliably under extreme conditions, including high temperatures, humidity, dust, and electrical interference.

Remote Access and Integration

Modern PLCs support integration with HMI (Human Machine Interface), SCADA (Supervisory Control and Data Acquisition), and cloud-based platforms, allowing operators to monitor and control air quality remotely.

The Role of tsxp572634m in PLC Systems

The tsxp572634m is a high-performance CPU module from Schneider Electric’s Modicon Premium series. It is specifically engineered for medium-to-large scale automation systems, making it ideal for complex air quality monitoring and control applications.

Key Features:

- High Processing Speed: Enables real-time data acquisition and control.

- Large Memory Capacity: Supports complex programs and extensive data logging.

- Multiple Communication Ports: Facilitates integration with diverse sensors and remote monitoring systems.

- Protocol Compatibility: Supports industry-standard protocols such as Modbus, CANopen, and Ethernet.

In air quality systems, the tsxp572634m processes data from multiple zones or facilities simultaneously. It allows for advanced programming logic to respond to specific air quality conditions. For instance, it can automatically increase airflow when CO2 levels rise, or activate HEPA filters when PM2.5 exceeds acceptable thresholds.

Integration of tsxrky12 for I/O Expansion

While the CPU handles logic and data processing, the physical interaction with the environment is managed through Input/Output (I/O) modules. The tsxrky12 is a 12-slot backplane rack that facilitates the expansion of I/O modules and connects them to the main CPU.

Benefits of Using tsxrky12:

- Modularity: Allows for the installation of various analog and digital I/O modules.

- Scalability: Easy to add or remove modules as requirements change.

- Compact Design: Space-efficient and ideal for centralized or distributed control systems.

- Enhanced Communication: Ensures seamless communication between CPU and peripheral devices.

Using the tsxrky12, engineers can design a system that accurately reads data from diverse sensors (gas, particulate, humidity) and controls a wide range of actuators (dampers, fans, filters). The modular nature of this system simplifies maintenance and future upgrades.

Example System Architecture

A typical air quality monitoring and control setup using tsxp572634m and tsxrky12 might include:

- Sensors: Devices for measuring CO2, CO, PM2.5, VOCs, humidity, and temperature.

- PLC CPU (tsxp572634m): Central controller executing real-time logic.

- I/O Rack (tsxrky12): Houses various I/O modules connected to sensors and actuators.

- HMI/SCADA Interface: For real-time visualization and manual overrides.

- Actuators: Controlled devices such as fans, dampers, valves, and filters.

Operational Flow Example:

- If VOC levels rise beyond safe limits, the sensor sends data to the CPU.

- The tsxp572634m processes this information and sends a signal to the actuator.

- The actuator might open a damper or start an exhaust fan.

- Simultaneously, an alert is displayed on the HMI for operator awareness.

Real-World Applications

PLC-based air quality control systems are utilized across a broad range of sectors:

Manufacturing Plants

Control of welding fumes, solvent emissions, and dust. PLCs ensure safe working environments and protect equipment.

Clean Rooms

Essential in electronics and pharmaceutical industries. PLCs manage strict requirements for particulate levels and humidity.

Commercial Buildings

Office complexes, shopping malls, and educational institutions use PLCs to balance indoor comfort and energy efficiency.

Waste Management Facilities

Monitors and controls emissions such as methane, ammonia, and other noxious gases to minimize environmental impact.

Hospitals and Laboratories

Ensures sterile environments by controlling airborne pathogens and maintaining pressure differentials between zones.

Future Trends in PLC-Based Air Quality Management

The future of PLC-based environmental control is rapidly evolving with advancements in IoT, AI, and edge computing. Some of the emerging trends include:

Predictive Maintenance

By analyzing historical data and real-time trends, AI algorithms can predict when filters need to be changed or when fans might fail, minimizing unplanned downtime.

Cloud Integration

Modern PLCs like the tsxp572634m support cloud connectivity, allowing for remote monitoring, control, and data storage.

Advanced Analytics

Big data analytics can help identify patterns, optimize performance, and reduce energy consumption by intelligently adjusting ventilation and filtration systems.

Cybersecurity Enhancements

As these systems become more interconnected, robust cybersecurity measures are critical to protect sensitive operational data and prevent unauthorized access.

Sustainability and Green Building Certifications

Integration with energy-efficient systems helps buildings achieve LEED or WELL certifications, demonstrating commitment to environmental responsibility.

Conclusion

PLC-based monitoring and control systems are revolutionizing how air quality is managed across various sectors. With the power of high-performance CPUs like the tsxp572634m and modular infrastructure enabled by the tsxrky12, businesses can deploy precise, reliable, and scalable air quality solutions. These systems not only ensure compliance with regulatory requirements but also create healthier and safer environments for workers and residents.

As technology continues to advance and environmental standards become more stringent, the integration of PLCs in air quality control will become even more vital. Investing in such intelligent systems today lays the foundation for a cleaner, safer, and more efficient tomorrow.