Why PLCs Are Essential for Intelligent EV Bike Design

Introduction

The electric vehicle (EV) industry is rapidly evolving, with new technologies driving advancements in performance, efficiency, and safety. Among these technologies, Programmable Logic Controllers (PLCs) play a critical role in managing and automating the complex systems within modern EV bikes. PLCs provide the intelligence that makes these vehicles not only functional but also efficient, reliable, and adaptable to future innovations.

In the context of intelligent EV bike design, PLCs help coordinate electrical systems, manage battery performance, and ensure safety features work seamlessly. Components like BMEH584040S and METSEPM5111 are key examples of the precision and efficiency that PLCs bring to this growing field.

Understanding PLCs in EV Technology

What is a PLC?

A Programmable Logic Controller (PLC) is an industrial computer used to automate electromechanical processes. It receives data from sensors, processes it according to a programmed logic, and triggers the appropriate outputs—such as controlling motors, lights, and safety circuits. In EV bikes, PLCs function as the brain that manages power distribution, speed control, and safety monitoring.

Why PLCs are Vital in Electric Bikes

Unlike traditional control systems, PLCs offer flexibility and scalability. This means designers can easily modify logic or add new features without redesigning the entire system. For EV bikes, this adaptability is essential as technology evolves to include smart connectivity, regenerative braking, and enhanced performance monitoring.

The Role of PLCs in Intelligent EV Bike Design

1. Efficient Power Management

One of the most critical aspects of EV bikes is power management. The PLC regulates power flow from the battery to the motor and other systems. By using high-performance modules such as BMEH584040S, designers can achieve precise control over current and voltage levels, preventing energy wastage and improving battery lifespan.

Battery Monitoring and Control

A PLC constantly monitors battery parameters such as temperature, voltage, and charge status. If the system detects any irregularities, it can automatically adjust power distribution or initiate safety protocols. This automation not only protects the battery but also ensures consistent performance.

2. Smart Sensor Integration

Modern EV bikes use multiple sensors for speed, torque, and temperature measurements. The PLC acts as a central hub that collects data from these sensors and processes it in real-time. For instance, when a rider accelerates, the PLC instantly analyzes throttle position and adjusts motor output for smooth performance.

Real-Time Data Processing

The METSEPM5111 power meter module helps monitor electrical parameters like current, voltage, and power factor in real-time. When integrated with the PLC system, it enhances accuracy in power monitoring, leading to better efficiency and predictive maintenance.

3. Enhanced Safety Systems

Safety is a top priority in EV bike design. PLCs ensure that all safety systems—such as braking control, motor protection, and emergency shut-offs—operate efficiently.

Overload and Fault Protection

By integrating modules like BMEH584040S, the PLC can detect overloads, short circuits, or temperature rises and immediately shut down the motor to prevent damage. These automated responses significantly reduce risks associated with electrical failures.

Regenerative Braking Coordination

PLCs are also instrumental in managing regenerative braking systems. They help control the energy flow back to the battery when the brakes are applied, maximizing energy recovery and reducing wear on mechanical parts.

4. Communication and Connectivity

As EV bikes become smarter, communication between different components is crucial. PLCs allow seamless integration of systems through communication protocols like Modbus, CAN, and Ethernet. This enables real-time data sharing between the motor controller, battery management system (BMS), and onboard diagnostics.

Cloud and IoT Integration

Intelligent EV bikes often connect to mobile apps or cloud platforms for monitoring and analytics. PLCs can be configured to transmit performance data such as energy consumption, speed trends, and fault reports. This integration helps in predictive maintenance and enhances user experience.

Using BMEH584040S and METSEPM5111 in EV Bike Systems

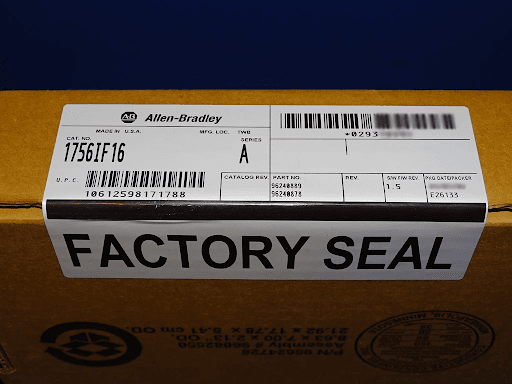

BMEH584040S: High-Performance Controller Module

The BMEH584040S is a high-capacity controller module designed for advanced automation systems. In EV bikes, it provides precise control over various subsystems such as motor drive, lighting, and charging circuits. Its reliability and speed make it ideal for handling real-time operations under dynamic conditions.

Benefits in EV Bike Design

-

Fast processing for sensor-based decisions

-

Supports complex logic for adaptive speed control

-

Enhances energy optimization and power flow regulation

-

Offers robust protection against system overloads

METSEPM5111: Advanced Power Metering Solution

The METSEPM5111 module is used for monitoring energy parameters with high accuracy. When paired with a PLC, it helps engineers assess the bike’s power consumption, efficiency, and battery health.

Key Advantages

-

Provides real-time voltage, current, and frequency data

-

Enables efficient power management through detailed analytics

-

Supports communication interfaces for IoT-based monitoring

-

Helps detect inefficiencies and optimize power usage

Together, these modules ensure that the EV bike operates efficiently while minimizing energy losses and maximizing performance reliability.

Benefits of PLC Integration in EV Bikes

Improved Efficiency

PLCs automate energy management and power delivery, minimizing losses and maximizing range per charge.

Higher Safety and Reliability

Automatic fault detection and self-correcting mechanisms reduce accidents and component wear.

Scalability and Customization

Designers can easily update the control logic or integrate new technologies without redesigning the entire electrical system.

Data-Driven Maintenance

With real-time diagnostics provided by modules like METSEPM5111, maintenance becomes predictive rather than reactive, reducing downtime and repair costs.

Future of PLCs in EV Innovation

As EV bikes continue to evolve, PLC technology will remain a cornerstone of innovation. Future PLCs will likely incorporate AI-driven decision-making, wireless connectivity, and self-learning algorithms that can adapt to rider behavior and environmental conditions. These advancements will lead to more efficient, safer, and smarter EVs that redefine urban mobility.

Conclusion

PLCs have become indispensable in the design and operation of intelligent EV bikes. They ensure smooth coordination of systems, precise power management, and enhanced safety—all essential for modern electric mobility. Components such as BMEH584040S and METSEPM5111 exemplify how automation and intelligent monitoring can revolutionize the performance and reliability of EV bikes.

As the demand for sustainable transportation grows, the integration of PLCs will continue to shape the future of EV engineering—making every ride smarter, safer, and more efficient.