How to Ensure Maximum Uptime with the Right Power Solution

In today’s fast-paced industrial and technological landscape, ensuring maximum uptime is more than just an operational goal—it’s a business necessity. Whether in manufacturing, automation, telecommunications, or energy systems, the power supply you choose determines the stability, performance, and longevity of your entire setup. Downtime not only disrupts productivity but can also lead to costly repairs and lost revenue. Choosing the right power solution is the key to uninterrupted operation and long-term reliability.

Understanding the Role of Power Solutions in Uptime

Every industrial or electronic system depends on a consistent and clean flow of power to function effectively. Power fluctuations, voltage drops, or sudden surges can cause equipment malfunction, data loss, or even permanent damage to sensitive components. The right power solution provides steady output, safeguards your system from irregularities, and ensures smooth operation even during unexpected changes in demand.

A high-quality industrial-grade unit—such as the 66C2105G01 Power Supply—is designed to handle varying environmental and load conditions without compromising performance. Selecting such robust and efficient units is essential for organizations aiming to minimize disruptions and maintain continuous productivity.

Key Factors That Affect System Uptime

To achieve maximum uptime, several technical and operational factors must be considered when choosing a power supply or designing a power distribution system.

1. Load Capacity and Power Rating

Matching your equipment’s power requirements with an appropriately rated power supply is the first step in preventing overloads and inefficiencies. Oversized systems waste energy, while undersized units overheat or fail prematurely. Conducting a detailed load analysis ensures that your power solution delivers consistent voltage and current under all operating conditions.

2. Power Quality and Stability

Voltage fluctuations, harmonics, and transients can cause serious harm to critical systems. A stable power supply filters out noise and irregularities, providing clean power to sensitive components. Units like the 66C2105G01 Power Supply are engineered with internal regulation and protection features that maintain power integrity even in demanding environments.

3. Environmental Conditions

Temperature, humidity, dust, and vibration can all impact a power unit’s lifespan. Industrial systems should be equipped with power supplies that have high tolerance for environmental stress. Choosing solutions with adequate cooling, rugged enclosures, and thermal protection helps maintain optimal performance over time.

4. Redundancy and Backup Systems

For mission-critical applications, redundancy is a must. Using dual or parallel power systems ensures that if one unit fails, the backup automatically takes over without interruption. This configuration greatly enhances uptime and provides peace of mind for operators managing essential systems.

Designing for Reliability and Efficiency

Proper System Integration

Even the best power supply cannot deliver maximum uptime if it’s poorly integrated into the system. Electrical engineers should ensure that wiring, connectors, and circuit protection devices are rated correctly. Additionally, the layout should allow for efficient heat dissipation and easy access for maintenance or replacement.

Preventive Maintenance

Regular inspections and preventive maintenance are vital to sustaining long-term reliability. Monitoring output voltage, checking for signs of wear or corrosion, and cleaning cooling vents can prevent unexpected failures. Establishing a maintenance schedule reduces the risk of unplanned downtime and keeps your power infrastructure in top shape.

Energy Efficiency

Efficient power conversion not only saves energy but also reduces heat buildup, extending the lifespan of both the power supply and connected equipment. Look for solutions with high efficiency ratings—typically above 90%—to minimize energy waste and operational costs.

Smart Monitoring and Diagnostics

Modern power systems come equipped with monitoring capabilities that allow technicians to track voltage levels, load conditions, and internal temperatures in real time. This data-driven approach helps detect anomalies early and take corrective action before failures occur. Investing in smart diagnostics tools is one of the most effective ways to ensure continuous uptime.

The Impact of Downtime on Operations

Even a few minutes of power loss can have a significant ripple effect on productivity, quality control, and customer satisfaction. In manufacturing, for instance, an unexpected shutdown can halt production lines and cause material waste. In IT systems, a power outage can lead to data loss or system crashes. The cost of downtime often far exceeds the investment required to install a reliable power solution.

A well-designed power infrastructure with dependable components—such as the 66C2105G01 Power Supply—acts as a safeguard against these risks. It ensures that energy delivery remains constant, even when external conditions fluctuate.

Choosing the Right Power Solution for Your Needs

Selecting the right power supply involves more than just matching voltage and current requirements. It requires evaluating the entire system’s operational demands, environment, and future scalability.

Assess Application Requirements

Identify the total load, operating voltage, and any peak demand that may occur during startup or heavy usage. This ensures that the power supply operates within safe parameters under all conditions.

Consider Future Expansion

As operations grow, so will the demand for power. Choosing a scalable and modular solution allows for future upgrades without complete system redesign.

Verify Compliance and Safety Standards

Ensure that your power supply meets industry certifications and safety standards. Compliance ensures reliability and reduces the risk of costly failures or nonconformities during audits.

Evaluate Support and Availability

Having access to replacement parts and technical support is crucial for maintaining uptime. Selecting a power solution that’s widely supported in the market simplifies maintenance and minimizes downtime in case of component replacement.

Best Practices for Sustained Uptime

- Keep detailed records of maintenance and inspections.

- Train staff on safe handling and troubleshooting procedures.

- Use surge protection and proper grounding techniques.

- Regularly test backup and redundancy systems.

- Replace aging units before they reach end-of-life specifications.

Adhering to these best practices helps maintain optimal performance and ensures that your operations continue running smoothly, even under challenging conditions.

Conclusion

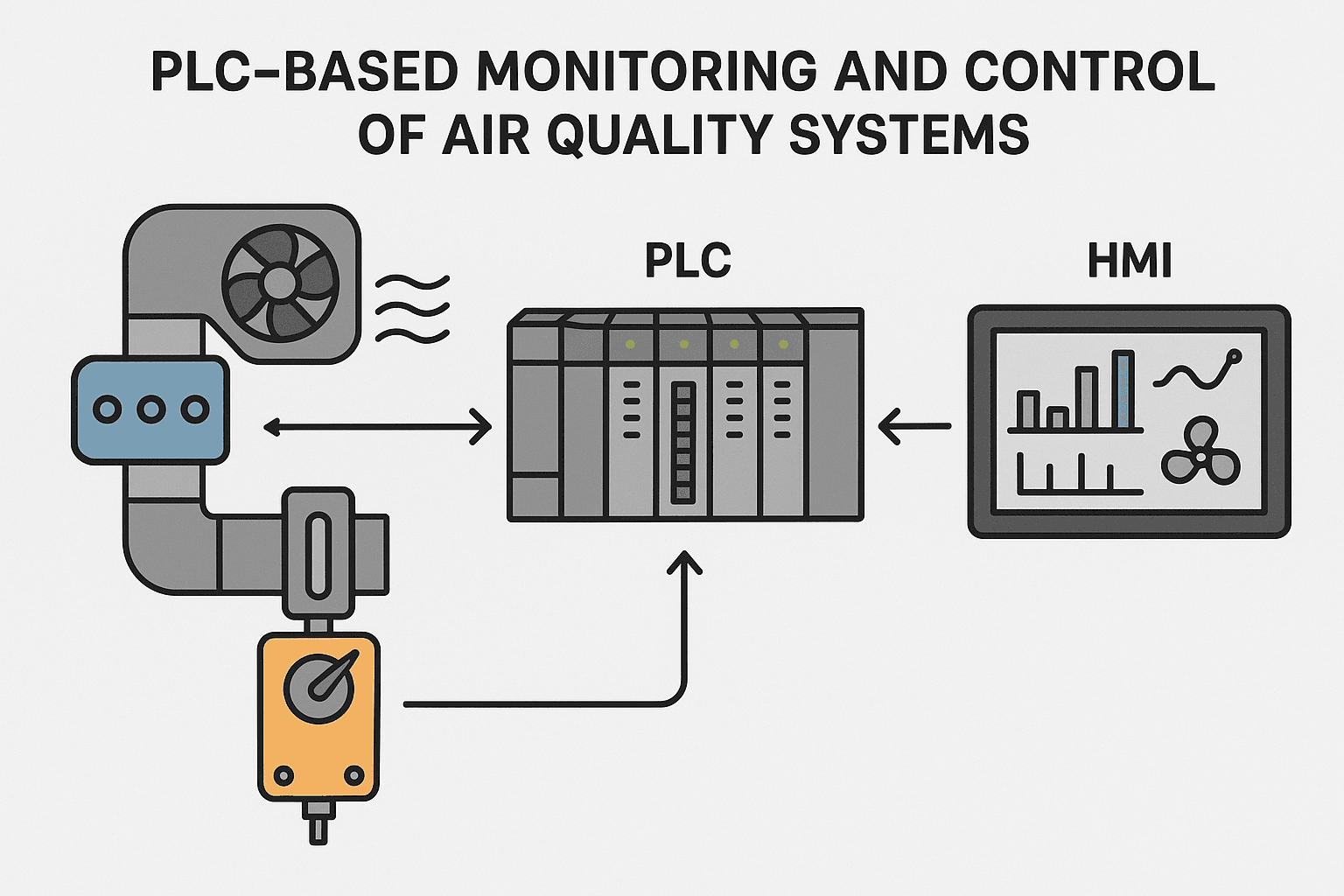

Ensuring maximum uptime begins with selecting a power solution designed for reliability, efficiency, and adaptability. The right system not only protects your equipment but also enhances operational stability and reduces long-term costs. By considering factors such as load capacity, environmental tolerance, and maintenance strategies, organizations can build resilient power infrastructures that deliver consistent performance. Whether you’re upgrading an existing setup or designing a new one, integrating dependable components—like the 66C2105G01 Power Supply and PLCHMI systems—can help achieve a more reliable, efficient, and productive operation.