A Guide to Selecting Industrial Measurement Devices for Your Application

Understanding the Importance of the Right Measurement Device

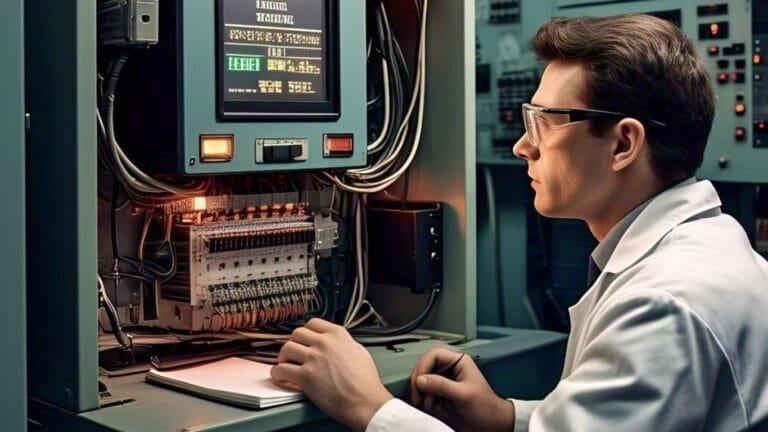

Industrial environments rely heavily on accurate measurement to maintain safety, efficiency, and product quality. Selecting the correct measurement device is not simply a technical decision—it directly affects operational reliability and long-term costs. A well-chosen instrument provides consistent data, minimizes downtime, and supports informed decision-making across processes.

In many facilities, engineers begin their evaluation by reviewing well-known reference models such as RED LION CONTROL APOLLO METER IMI04113, which helps define expectations for accuracy, display clarity, and compatibility with existing systems. Using such reference points allows teams to establish performance benchmarks before comparing alternatives.

Equally important is understanding how measurement devices interact with protective and control components within the system. Electrical safety, load management, and fault protection are closely tied to proper measurement and control coordination, often considered alongside devices like ABB BREAKER 1S261-B63 to ensure a balanced and secure system design.

Key Factors to Consider When Selecting Industrial Measurement Devices

Accuracy and Resolution Requirements

Accuracy is the foundation of any measurement device. Before selecting an instrument, define the acceptable tolerance levels for your application. High-precision processes, such as chemical dosing or energy monitoring, require instruments with finer resolution and minimal drift over time. Lower-precision applications may prioritize durability over extreme accuracy.

Resolution determines how small a change the device can detect. Choosing a resolution that aligns with process variability ensures meaningful data without unnecessary complexity or cost.

Environmental and Operating Conditions

Industrial settings can be harsh. Temperature extremes, humidity, dust, vibration, and electromagnetic interference all influence device performance. Measurement instruments should be rated for the environment in which they operate, including enclosure type and ingress protection.

Failing to consider environmental factors can lead to inaccurate readings or premature failure. Always match device specifications with real-world conditions rather than ideal laboratory assumptions.

Matching Device Type to Application Needs

Electrical Measurements

For electrical applications, measurement devices may monitor voltage, current, frequency, or power consumption. The selected instrument must support the correct input ranges and electrical standards. Isolation and safety ratings are especially critical to protect both personnel and equipment.

Devices used in electrical systems should integrate smoothly with protective components and control panels, ensuring that measurement data contributes to system stability and fault detection.

Process and Flow Measurements

In process industries, measurement devices often track variables such as pressure, temperature, flow, and level. Each variable requires a different sensing technology, and the choice depends on process media, response time, and maintenance requirements.

For example, continuous processes benefit from devices with fast response times and stable long-term output, while batch processes may prioritize repeatability and ease of calibration.

Integration and Communication Capabilities

Compatibility with Control Systems

Modern industrial environments depend on interconnected systems. Measurement devices should support common communication protocols to integrate with controllers, data loggers, and supervisory systems. This connectivity enables centralized monitoring, alarms, and data analysis.

Before selecting a device, confirm that it can communicate with existing infrastructure without requiring extensive modification or additional hardware.

Data Logging and Visualization

Beyond raw measurement, many applications require trend analysis and historical data. Devices with built-in logging or easy data export simplify diagnostics and performance optimization. Clear displays and intuitive interfaces also reduce operator error and training time.

Installation, Calibration, and Maintenance Considerations

Ease of Installation

A measurement device that is difficult to install can increase commissioning time and labor costs. Consider mounting options, wiring accessibility, and configuration procedures. Compact designs and standardized connections often reduce installation complexity.

Planning installation requirements early helps avoid surprises during deployment and ensures a smoother startup.

Calibration and Long-Term Stability

All measurement devices require calibration to maintain accuracy. Selecting instruments with stable sensors and straightforward calibration procedures reduces maintenance effort. Some devices support field calibration, allowing adjustments without removal from service.

Long-term stability is especially important in applications where frequent recalibration would disrupt operations.

Safety and Compliance Requirements

Regulatory Standards

Industrial measurement devices must comply with relevant safety and performance standards. Compliance ensures legal operation and reduces risk during inspections or audits. Always verify certifications related to electrical safety, environmental protection, and industry-specific regulations.

Using compliant devices also protects organizations from liability associated with inaccurate measurements or unsafe installations.

Risk Reduction and Reliability

Reliable measurement supports proactive maintenance and early fault detection. Devices that provide consistent data help identify abnormal conditions before they escalate into failures. This reliability contributes to safer working conditions and lower operational risk.

Cost, Scalability, and Future-Proofing

Balancing Cost and Performance

While initial cost is an important consideration, it should not outweigh performance and reliability. A lower-cost device may lead to higher expenses over time due to maintenance, downtime, or replacement. Evaluate total cost of ownership rather than purchase price alone.

Planning for Expansion

Industrial systems often evolve. Selecting measurement devices that support additional inputs, expanded ranges, or upgraded communication options helps future-proof the installation. Scalable solutions reduce the need for complete replacements as requirements change.

Conclusion

Selecting the right industrial measurement device requires a balanced evaluation of accuracy, environment, integration, safety, and long-term value, especially when it must operate reliably alongside protective components such as ABB BREAKER 1S261-B63. By clearly defining application requirements and considering how each factor affects performance, organizations can choose instruments that enhance efficiency and reliability across the entire system. Thoughtful selection not only improves current operations but also supports future growth and technological advancement while maintaining safe and stable electrical infrastructure.