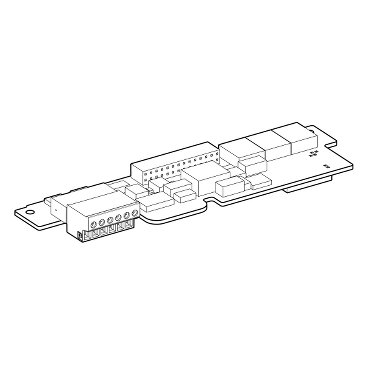

TRICONEX 3008 PROCESSOR MODULE

Original price was: $7,839.00.$6,030.00Current price is: $6,030.00.

1 in stock

Free shipping on orders over $5000!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

No products in the basket.

$7,839.00 Original price was: $7,839.00.$6,030.00Current price is: $6,030.00.

1 in stock

Free shipping on orders over $5000!