PLC Data Logging and Custom PLC Solutions

Introduction

Programmable Logic Controllers (PLCs) are essential components in industrial automation, providing robust control and monitoring solutions across various applications. This article explores three critical aspects of PLCs: data logging, custom PLC solutions and PLCs for bigineers.

What is a PLC?

A Programmable Logic Controller (PLC) is a specialized computer used to control machinery and processes in industrial environments. It is designed to handle complex control tasks with high reliability and flexibility. PLCs are integral to manufacturing lines, energy management systems, and other industrial applications where precise control and monitoring are necessary.

History and Evolution of PLCs

PLCs were first developed in the late 1960s to replace relay-based control systems. The first PLC, the Modicon 084, was introduced in 1968 and revolutionized industrial automation by offering programmable and flexible control systems. Over the years, PLCs have evolved to include advanced features such as real-time processing, enhanced communication capabilities, and integration with other industrial systems like SCADA and MES.

PLC for Beginners

Understanding the Basics

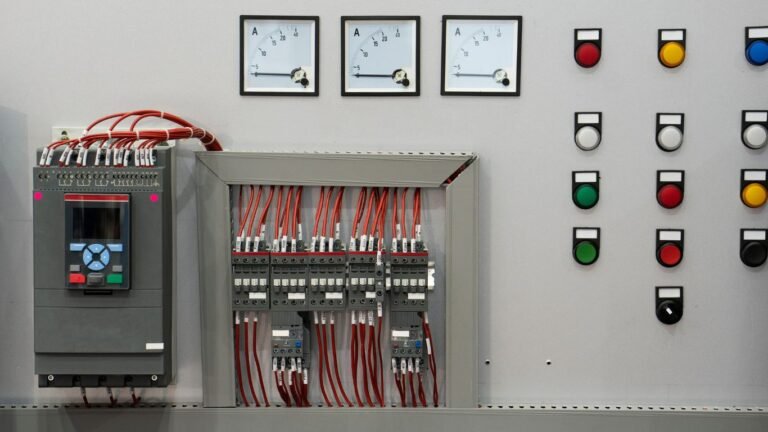

For beginners, understanding the fundamentals of PLCs is crucial. A PLC consists of a central processing unit (CPU), input/output (I/O) modules, power supply, and communication interfaces. The CPU executes control instructions stored in its memory, while I/O modules interface with sensors and actuators to monitor and control processes.

Key Components of a PLC

- Central Processing Unit (CPU): The brain of the PLC, responsible for executing control logic.

- Input/Output (I/O) Modules: Interface with external devices such as sensors (inputs) and actuators (outputs).

- Power Supply: Provides the necessary power to the PLC and its components.

- Communication Interfaces: Enable the PLC to communicate with other devices and systems.

Basic Programming Concepts

PLCs are typically programmed using ladder logic, a graphical programming language resembling electrical relay logic diagrams. Other programming languages include Function Block Diagram (FBD), Structured Text (ST), and Sequential Function Chart (SFC). Beginners should start with ladder logic due to its simplicity and ease of understanding.

Getting Started with PLC Programming

- Choose a PLC Brand: Popular brands include Siemens, Allen-Bradley, and Schneider Electric.

- Select a Programming Software: Each brand has its own software, such as Siemens’ TIA Portal or Allen-Bradley’s RSLogix.

- Learn Basic Instructions: Start with simple instructions like contacts, coils, and timers.

- Create Simple Programs: Write basic programs to control simple processes, such as turning a light on and off.

- Test and Debug: Use simulation tools provided by the programming software to test and debug your programs.

Practical Applications for Beginners

Beginners can start with simple applications to gain hands-on experience. Examples include:

- Traffic Light Control: Simulate the control of traffic lights at an intersection.

- Conveyor Belt System: Control the movement of a conveyor belt based on sensor inputs.

- Temperature Control: Use a temperature sensor to control a heating element.

PLC Data Logging

Importance of Data Logging

Data logging is the process of collecting and storing data over time for analysis and monitoring purposes. In industrial automation, data logging is crucial for:

- Process Optimization: Analyzing data to identify inefficiencies and optimize processes.

- Predictive Maintenance: Monitoring equipment performance to predict and prevent failures.

- Compliance and Reporting: Ensuring processes comply with regulatory standards and generating reports for audits.

How PLC Data Logging Works

PLC data logging involves capturing data from sensors, actuators, and other devices connected to the PLC. The data is then stored in memory or transmitted to external storage devices or systems for further analysis. Key components of a data logging system include:

- Sensors and Actuators: Collect real-time data from the process.

- PLC Memory: Temporarily stores the data before it is transmitted.

- Communication Interfaces: Transmit data to external storage or analysis systems.

- Data Storage: External databases or cloud storage systems that hold the logged data.

Setting Up PLC Data Logging

- Define Data Points: Identify the specific data points you need to log (e.g., temperature, pressure, flow rate).

- Configure I/O Modules: Set up the I/O modules to collect data from the sensors and actuators.

- Program Data Logging Instructions: Write PLC programs to read and store the data points at specified intervals.

- Set Up Communication: Configure communication interfaces to transmit data to external storage or monitoring systems.

- Implement Data Storage: Use databases, cloud storage, or local storage systems to save the logged data.

Applications of PLC Data Logging

PLC data logging is widely used in various industries, including:

- Manufacturing: Monitoring production processes and equipment performance.

- Energy Management: Tracking energy consumption and optimizing energy use.

- Water Treatment: Monitoring water quality parameters and controlling treatment processes.

- HVAC Systems: Logging temperature, humidity, and airflow data for climate control.

Challenges and Solutions in PLC Data Logging

- Data Volume: Large volumes of data can overwhelm storage systems. Solution: Use data compression and efficient storage techniques.

- Data Accuracy: Ensuring data accuracy and reliability is critical. Solution: Implement calibration and validation procedures.

- Real-Time Processing: Real-time data processing can be challenging. Solution: Use high-performance PLCs and optimized programming techniques.

- Integration: Integrating data logging systems with other industrial systems can be complex. Solution: Use standardized communication protocols and middleware.

Custom PLC Solutions

Benefits of Custom PLC Solutions

Custom PLC solutions are tailored to meet the specific needs of an application or process. Benefits include:

- Flexibility: Custom solutions can be designed to fit unique requirements and constraints.

- Scalability: Custom PLCs can be scaled up or down based on the application’s needs.

- Efficiency: Optimized for specific tasks, custom solutions can improve efficiency and performance.

- Cost-Effectiveness: By focusing on necessary features, custom solutions can reduce costs.

Designing Custom PLC Solutions

- Requirement Analysis: Identify the specific requirements and constraints of the application.

- System Design: Develop a detailed design that includes hardware, software, and communication components.

- Component Selection: Choose the appropriate PLC, I/O modules, and other components.

- Programming: Write custom programs tailored to the application’s requirements.

- Testing and Validation: Test the system thoroughly to ensure it meets the design specifications.

Examples of Custom PLC Solutions

- Automated Assembly Line: A custom PLC solution designed to control and monitor an automated assembly line, ensuring precise coordination between robots, conveyors, and other equipment.

- Energy Management System: A tailored PLC solution for monitoring and optimizing energy use in a manufacturing facility, integrating with renewable energy sources and energy storage systems.

- Water Treatment Plant: Custom PLCs designed to control and monitor the various stages of water treatment, ensuring compliance with regulatory standards and optimizing treatment processes.

Implementing Custom PLC Solutions

- Project Planning: Develop a detailed project plan that outlines the steps and timeline for implementation.

- System Integration: Integrate the custom PLC solution with existing systems and infrastructure.

- Training and Support: Provide training for operators and maintenance personnel, and offer ongoing support to ensure smooth operation.

- Monitoring and Optimization: Continuously monitor the system’s performance and make necessary adjustments to optimize efficiency and effectiveness.

Conclusion

Programmable Logic Controllers (PLCs) are indispensable in modern industrial automation, offering robust control, monitoring, and data logging capabilities. For beginners, understanding the basics of PLCs and getting started with simple programming tasks is crucial. PLC data logging plays a vital role in process optimization, predictive maintenance, and regulatory compliance, while custom PLC solutions provide tailored, efficient, and cost-effective automation systems. By leveraging these aspects, industries can enhance productivity, efficiency, and reliability, ensuring continued success in an increasingly automated world. We are PLCHMI, provide all type of support services for PLCs and HMIs around the word.

FAQs

What is a PLC?

A Programmable Logic Controller (PLC) is a specialized computer used to control and monitor industrial processes and machinery.

How does PLC data logging benefit industries?

PLC data logging helps optimize processes, predict maintenance needs, and ensure compliance with regulatory standards.

What are custom PLC solutions?

Custom PLC solutions are tailored automation systems designed to meet the specific needs of an application or process.

How can beginners start with PLC programming?

Beginners can start with ladder logic programming, using simple instructions and creating basic programs to control simple processes.

Why are PLCs important in industrial automation?

PLCs provide reliable and flexible control and monitoring solutions, essential for efficient and effective industrial automation. PLCHMI.shop is a reliable place to buy SE controllers.