How Advanced Input Modules Improve Industrial Automation Systems

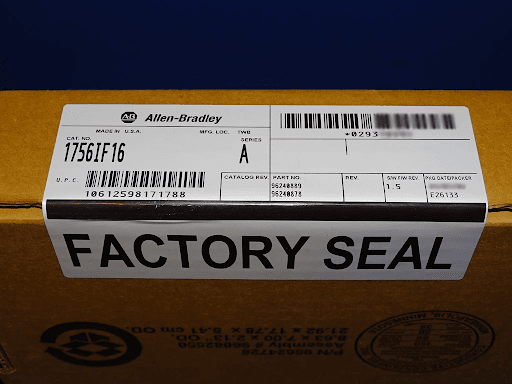

In today’s fast-paced industrial world, automation has become the cornerstone of productivity, precision, and efficiency. Modern factories and production facilities rely heavily on advanced control systems to streamline operations and reduce human error. Among the critical components of these systems are input modules such as 1756-IF16A Allen-Bradley, which serve as the vital link between field devices and controllers. These advanced input modules not only gather accurate data but also enhance the overall performance, reliability, and responsiveness of industrial automation systems.

Understanding the Role of Input Modules in Automation

Input modules are essential components in programmable control systems. They receive signals from sensors, transmitters, and other field instruments, converting them into digital data that a controller can interpret. Whether monitoring temperature, pressure, flow, or level, these modules ensure precise data collection for efficient decision-making.

In complex systems such as PLCHMI, input modules form the foundation of reliable communication between machines and operators. They allow the controller to read real-world conditions accurately and adjust processes accordingly, ensuring continuous operation with minimal downtime.

Why Advanced Input Modules Matter

Traditional input modules have served industries for decades, but as automation technology has evolved, so have the expectations for performance and reliability. Advanced input modules bring several improvements that address modern industrial challenges.

1. Higher Accuracy and Signal Stability

Advanced input modules are designed with superior signal filtering and noise reduction features. This allows them to capture data more accurately, even in environments with high electrical interference. For example, in applications involving 1756-IF16A Allen-Bradley, precise analog input readings ensure consistent process control and better end-product quality.

2. Faster Response Times

In high-speed manufacturing and critical operations, timing is everything. Advanced modules process signals faster, allowing control systems like PLCHMI to react immediately to changing conditions. This level of responsiveness helps prevent equipment damage and ensures smooth, uninterrupted workflows.

3. Greater Flexibility and Configuration Options

Modern input modules can be configured to handle various signal types—voltage, current, or resistance—making them suitable for diverse applications. They also offer programmable parameters for scaling, filtering, and diagnostics, enabling users to tailor the module’s performance to specific process needs.

Integration with Modern Automation Systems

Automation systems today are highly integrated, relying on seamless communication between multiple devices. Input modules play a crucial role in maintaining that connection.

Compatibility with Advanced Control Platforms

Advanced input modules can easily integrate with programmable controllers and human-machine interfaces. Systems like PLCHMI benefit from this integration by providing real-time monitoring and data visualization. Operators can see exactly what’s happening in each process and make adjustments quickly when necessary.

Enhanced Communication Protocols

Many modern modules support multiple communication standards such as Ethernet/IP, Modbus, or DeviceNet. These protocols enable fast, secure, and reliable data exchange between field devices and control units. Integration becomes easier and more scalable as systems expand or evolve.

Simplified Maintenance and Diagnostics

One of the standout features of advanced input modules is their built-in diagnostic capability. They can detect wiring errors, signal faults, and calibration issues automatically. For example, in an application using 1756-IF16A Allen-Bradley, technicians can identify input signal problems without halting production, minimizing downtime and maintenance costs.

Improving Efficiency and Productivity

1. Data Accuracy for Better Decision Making

Accurate data is vital for any automated process. Advanced input modules ensure that every measurement transmitted to the controller is precise. In systems utilizing PLCHMI, this accuracy translates to improved process optimization, energy efficiency, and reduced waste.

2. Enhanced Safety in Industrial Environments

Safety is a top priority in industrial automation. Input modules continuously monitor field sensors that detect pressure, temperature, or hazardous conditions. With advanced features, they can trigger alarms or shutdowns instantly, preventing accidents and equipment damage.

3. Energy and Cost Savings

Modern input modules contribute to energy efficiency by ensuring that machines operate only when needed and at optimal performance levels. Reduced error rates and downtime mean lower operating costs and longer equipment life.

The Role of Input Modules in Digital Transformation

The rise of smart manufacturing and Industry 4.0 has pushed companies to adopt more intelligent and connected systems. Input modules are a key part of this transformation, providing the essential link between physical processes and digital data.

Real-Time Data Collection

In an industrial environment, conditions can change rapidly. Advanced input modules ensure real-time data collection, allowing PLCHMI systems to analyze and respond without delay. This capability supports predictive maintenance, quality control, and improved production scheduling.

Remote Monitoring and Control

With network-enabled input modules, operators can access system information remotely. Whether managing a single plant or multiple facilities, remote control capabilities provide greater flexibility and efficiency. This connectivity ensures that operations remain consistent even when managed from a distance.

Scalability for Future Expansion

As industries grow, so do their automation needs. Advanced input modules are designed to scale easily. They can be added or upgraded without major system overhauls, ensuring compatibility with future technologies like 1756-IF16A Allen-Bradley and other advanced control systems.

Practical Considerations for Using Advanced Input Modules

Proper Installation and Calibration

To maximize performance, input modules should be installed and calibrated according to manufacturer specifications. Proper grounding and shielding are essential to minimize electrical noise and ensure data accuracy.

Regular Maintenance

Although advanced modules require minimal maintenance, periodic inspections help identify potential issues before they affect system performance. Regular cleaning, firmware updates, and signal testing keep the module functioning optimally.

Training and System Familiarity

Operators and technicians should be well-trained in handling advanced input modules and associated control systems. Familiarity with configurations, alarms, and troubleshooting procedures ensures safe and efficient operation.

Conclusion

Advanced input modules have revolutionized the way automation systems collect and interpret data. They enhance precision, reliability, and connectivity—three pillars of modern industrial success. By integrating intelligent modules with systems like PLCHMI, industries can achieve higher efficiency, real-time monitoring, and predictive capabilities that redefine productivity standards.

As technology continues to evolve, innovations such as 1756-IF16A Allen-Bradley will play an even greater role in advancing industrial automation. Investing in these intelligent solutions ensures not just operational efficiency today, but a future-ready system capable of adapting to tomorrow’s challenges.