How Modern Automation Hardware Improves Industrial Efficiency And Reliability Today

Modern industrial automation systems rely on powerful control hardware and communication modules to run complex processes with high efficiency and minimal downtime. As industries evolve, so does the demand for fast, reliable automation equipment that can handle increasing workloads and integrate seamlessly with plant-wide networks. In this article, we explore how advanced automation hardware delivers improved operational performance and system reliability, transforming manufacturing and process industries around the world.

The Rise of Intelligent Control Systems

Industrial automation hardware has progressed significantly over the past decades, moving from basic relay logic to highly advanced programmable controllers and networked modules. Control systems are now expected not only to manage simple on/off commands but also to perform intricate logic, process large volumes of data, and communicate with other systems in real time. These capabilities are essential for optimizing efficiency and ensuring consistent product quality.

At the core of these advances are central processing units that execute control logic, handle communication tasks, and coordinate peripheral devices. A strong example of this is the 140CPU53414A – QUANTUM 534 PLC CONTROLLE, a CPU module designed for large and sophisticated automation applications with scalable architecture and support for multiple communication interfaces.

When paired with a network communication module like the 140NOE77100 – Ethernet network TCP/IP module, systems gain the ability to transfer data rapidly across plant networks using TCP/IP standards. These modules facilitate communication between controllers, SCADA interfaces, HMIs, and higher-level systems, ensuring that production data flows smoothly and control loops remain responsive.

Reducing Downtime With Reliable Control Hardware

A key benefit of modern automation hardware is increased reliability. CPUs designed for industrial environments provide robust performance with large memory capacities and deterministic execution of control logic. These processors are housed in rugged frames that withstand temperature variations, electrical noise, and vibration typical on factory floors. The result is reduced equipment failure and less unplanned downtime, which directly improves plant productivity.

Network modules like the Ethernet TCP/IP module shown earlier offer redundancy options and robust communication pathways. Redundant network designs ensure that even if a segment fails, alternate communication routes can maintain control operations without interrupting production. Additionally, standardized protocols like Ethernet TCP/IP help integrate devices from different parts of the plant, simplifying system expansion and maintenance.

Seamless Communication With Industrial Networks

Today’s automation hardware doesn’t operate in isolation. Controllers and modules must exchange data across complex networks using standard protocols. Ethernet-based communication has become the backbone of many industrial networks, enabling real-time control and information exchange over the same infrastructure used for business systems.

Modules like Ethernet TCP/IP adapters provide plant-wide connectivity using familiar network standards. They allow automation hardware to communicate using protocols such as Modbus TCP/IP, enabling easier communication between controllers, databases, and supervisory systems. This use of standardized networking improves interoperability and reduces the need for proprietary networking solutions, lowering overall system costs.

For larger systems, network modules also support diagnostic tools and web interfaces that help engineers monitor network health, configure devices, and troubleshoot issues remotely, further enhancing operational reliability and reducing maintenance time.

Scalability and Flexibility in Automation Hardware

Modern automation platforms are designed with scalability in mind. Whether you’re controlling a single machine or an entire production line, modular hardware allows you to expand capabilities as required. CPUs with high processing power handle more complex logic, and communication modules enable distributed control across multiple remote stations.

This flexibility means companies can adapt to changing production needs without a complete overhaul of the control system. Adding new I/O modules or communication interfaces can extend system capabilities without disrupting ongoing operations. For example, a control system initially designed for a single process can grow into a plant-wide networked control system, all while maintaining performance and reliability.

Data-Driven Decision Making and Process Optimization

One of the most impactful advantages of modern control hardware and network modules is their contribution to data-driven decision making. As automation systems become more interconnected, vast amounts of performance and operational data are generated. This data can be collected and analyzed to identify bottlenecks, predict equipment failures, and optimize resource usage.

Controllers with networking capabilities, including those that support Ethernet TCP/IP communication, can stream data to analytics platforms or cloud services. This capability enables organizations to move from reactive to proactive maintenance models and make strategic decisions based on real-time performance metrics.

Furthermore, streamlined data flow helps engineering teams visualize system status through dashboards and integrate smart alerts and triggers, which improves responsiveness and minimizes costly delays.

Applications Across Diverse Industries

The benefits of modern automation hardware extend across numerous industries:

- Manufacturing: Controllers and network modules streamline production lines, ensure synchronized machine coordination, and enable precise control of batch processes.

- Energy: Power generation and distribution systems use rugged control hardware for monitoring and controlling substations, turbines, and renewable energy sources.

- Oil & Gas: Reliable CPUs and communication modules control drilling operations, safety shutdown systems, and pipeline monitoring to maintain safety and efficiency.

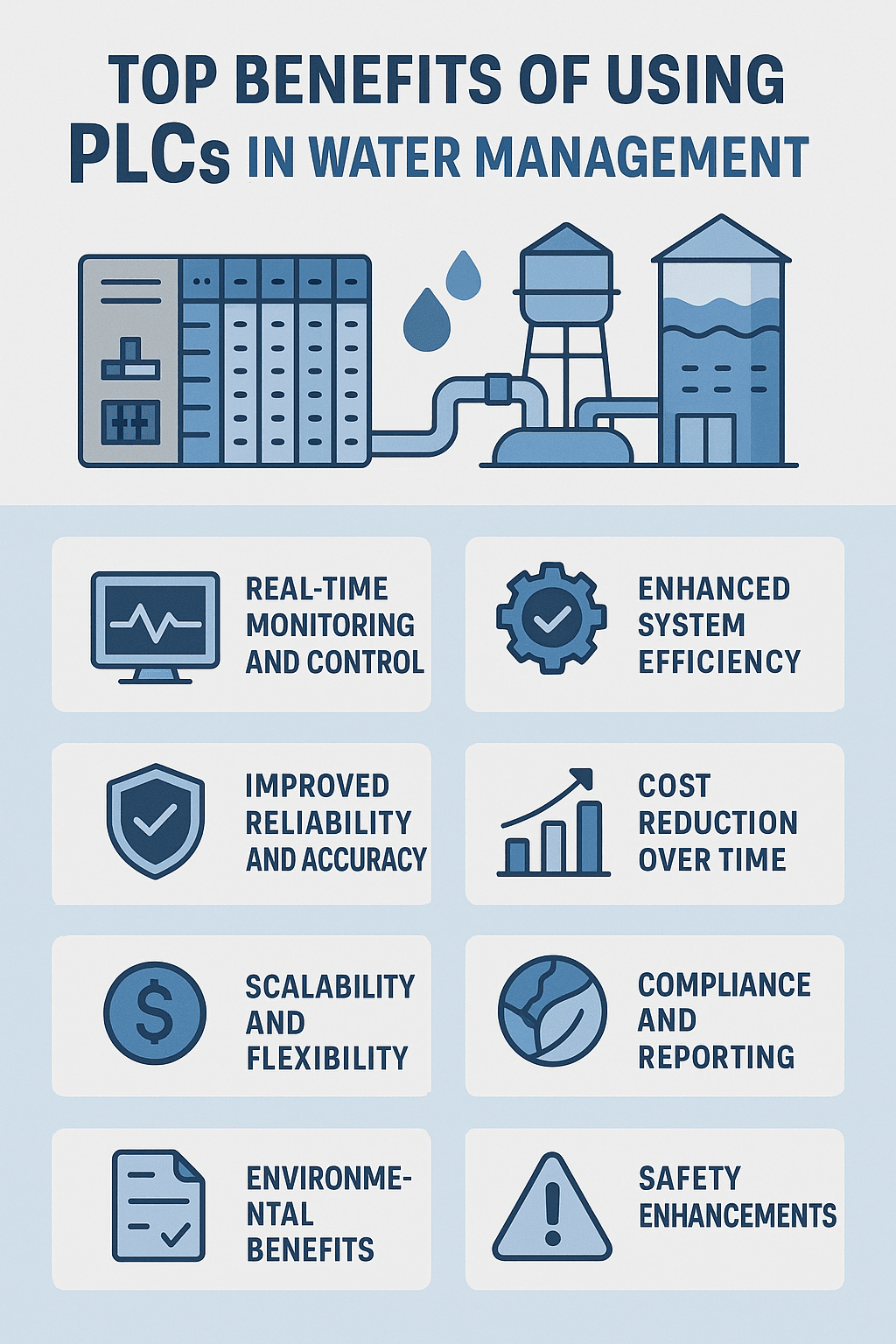

- Water Treatment: Automation systems manage pumps, chemical dosing, and filtration processes using real-time networked data to ensure clean and safe water distribution.

- Food & Beverage: These industries benefit from precise control algorithms and networking for traceability, quality control, and regulatory compliance.

Across all these sectors, the combination of powerful controllers and robust communication modules spells greater uptime, better efficiency, and lower operational risks.

Competitive Landscape: Control Hardware and Network Modules

Below is a simple comparison table showing how the discussed products stack up against typical competitors in the market. These competitors represent similar automation CPU and Ethernet communication module offerings from well-known industrial automation brands.

| Product Type | Example Core Control Module | Key Competitor Models |

| CPU / Controller | 140CPU53414A – QUANTUM 534 PLC CONTROLLE | Siemens S7-1500 CPU series, Allen-Bradley ControlLogix series, Mitsubishi MELSEC series |

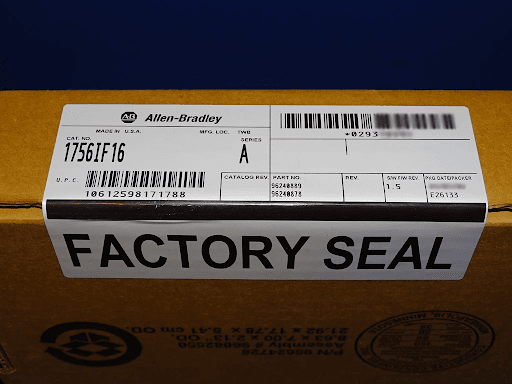

| Ethernet Network Module | 140NOE77100 – Ethernet network TCP/IP module | Allen-Bradley 1756-ENET EtherNet/IP module, Siemens CP 1543 Ethernet module, Mitsubishi Ethernet interface modules |

This table illustrates how the products you’re focusing on fit within a broader ecosystem of industrial controllers and Ethernet communication devices. Engineers often choose specific models based on system requirements, integration needs, and existing infrastructure, but the underlying goals remain the same: robust control and seamless communication.

Conclusion

Modern automation hardware, including programmable control units and advanced Ethernet communication modules such as the 140NOE77100 – Ethernet network TCP/IP module, has transformed the way industrial systems operate. With enhanced processing power, network connectivity, and rugged durability, these components drive higher system efficiency, better data visibility, and stronger reliability across industrial processes. By leveraging advanced control platforms and network modules, organizations achieve faster response times, reduced downtime, and more informed decision-making. As industrial automation continues to evolve, these technologies will remain central to building smarter, more resilient, and more efficient operations.