Optimizing Fan Systems with PLCs for Energy Efficiency

In today’s competitive artificial geography, energy effectiveness has become a critical focus for associations seeking to reduce functional costs and minimize their carbon footprint. One of the crucial areas where energy savings can be achieved is through the optimization of HVAC systems. Addict systems are pivotal factors in colorful diligence, from HVAC (heating, ventilation, and air conditioning) systems to manufacturing processes. By using programmable logic controllers (PLCs), associations can enhance the performance and energy effectiveness of their addict systems, increasing both functional trustability and sustainability.

The part of PLCs in Fan Systems

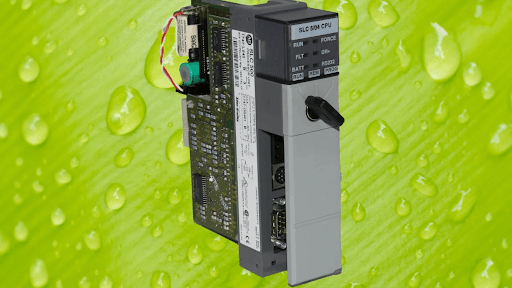

A programmable logic controller (PLC) is a digital computer used for robotization of electromechanical processes, such as controlling ministry, plant assembly lines, or addict systems. The integration of PLCs in addict systems enables more precise control, allowing for real-time adaptations grounded on colorful factors such as temperature, tailwind, and pressure. By optimizing addict speed and functional parameters, PLCs can significantly ameliorate the energy consumption of the system.

Crucial Benefits of PLC Integration for Fan Systems

Energy effectiveness Through Variable Speed Control Traditionally, addict systems operate at a constant speed, leading to gratuitous energy consumption. By exercising PLCs to apply variable speed drives (VSDs), the speed of the addict motor can be acclimated stoutly according to the demand, reducing power operation when full capacity is n’t needed. This process is especially important for large artificial systems where suckers operate continuously and consume substantial quantities of energy.

Real-time monitoring and adaptations: PLCs offer the capability to continuously cover system parameters, such as air pressure, temperature, and moisture. With detectors connected to the PLC system, drivers can dissect real-time data and make necessary adaptations to the addict system to optimize performance. This visionary approach helps in relating inefficiencies and avoiding gratuitous energy consumption.

Automated Control of Multiple Suckers: In some artificial surroundings, multiple addict systems operate together to maintain optimal conditions. PLCs can attend to these suckers, ensuring that they operate efficiently and in harmony, without overstepping any single unit. This results in smoother operation and lower energy consumption.

Scheduling and preventative conservation: Another crucial advantage of PLCs is the capability to record addict system operations grounded on demand. For example, PLCs can be programmed to operate suckers only during peak hours, reducing energy waste during off-hours. Also, PLCs can give individual information that allows for prophetic and preventative conservation, reducing time-out and ensuring that the addict systems operate at peak effectiveness.

Case Studies Using PLCs to Optimize Fan Systems

Several diligences have formerly espoused PLCs to optimize their addict systems, demonstrating notable advancements in energy effectiveness.

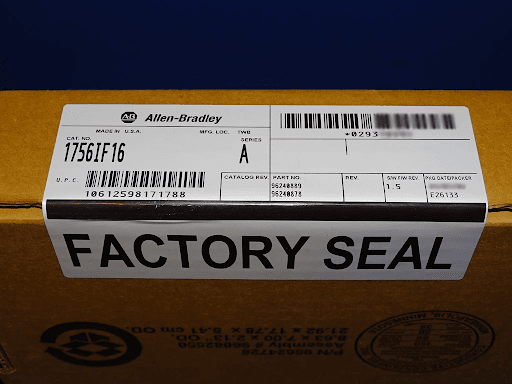

HVAC Systems in Commercial Structures: A marketable structure using HVAC systems can see substantial energy savings by exercising PLCs for controlling addict systems. By enforcing BMEAHO0412, a modular PLC result designed for heating, ventilation, and air exertion systems, structure directors can cover and acclimate addict speed grounded on residency situations, rainfall conditions, and inner air quality. This dynamic control ensures that suckers only operate at full speed when necessary, reducing energy consumption by over 30%.

Industrial Ventilation in Manufacturing Shops: A manufacturing factory uses a network of suckers to ensure proper ventilation. By integrating BMXP3420102, an advanced PLC module, into the system, factory drivers can maintain tailwind in optimal situations while conforming addict pets according to the manufacturing process’s specific requirements. This approach reduces the wear and tear and gas on the outfit and lowers overall energy operation, furnishing a significant return on investment in energy savings.

Enforcing-Grounded Addict System Optimization

To apply energy-effective addict systems using PLCs, companies must first assess the conditions of their specific operations. Then there are a many way to consider

Estimate Being System: Understand the current operation of the addict system, including the cargo conditions, functional schedule, and energy consumption patterns.

Elect the Right PLC: Modules Choose the applicable PLC tackle and software to match the specific requirements of the addict system. Modules similar to BMEAHO0412 and BMXP3420102 offer excellent comity for HVAC and artificial operations, icing flawless integration with being systems.

Install Detectors for Data Collection: Integrating detectors into the addict system allows for nonstop monitoring of variables like tailwind, temperature, and pressure. This data is pivotal for optimizing performance through real-time adaptations.

Program Control Logic: Use the PLC’s programming capabilities to develop a sense for addict operation, incorporating variable speed control, scheduling, and system synchronization for multiple suckers.

Monitor and Fine-Tune the System After installation, cover the performance of the system and fine-tune the control parameters to achieve the stylish energy-saving issues.

Conclusion

Optimizing addict systems with PLCs is an important approach to achieving significant energy savings in artificial and marketable operations. By enforcing results like BMEAHO0412 and BMXP3420102, associations can harness the full potential of their addict systems, ensuring effective operation while reducing costs. The integration of real-time monitoring, automated control, and prophetic conservation through PLCs enhances the trustability and sustainability of addict systems, making them a foundation of ultramodern energy-effective operations.