PLC and HMI Integration for Better Industrial Data Collection

Introduction

In cutting edge mechanical mechanization, the integration of Programmable Rationale Controllers (PLCs) and Human-Machine Interfacing (HMIs) is fundamental for productive information collection, real-time observing, and moved forward decision-making. This integration upgrades operational effectiveness, decreases downtime, and gives significant bits of knowledge for superior handle control.

The Significance of PLC and HMI Integration

PLCs are dependable for executing control rationale, whereas HMIs serve as an interface for administrators to screen and associated with the framework. The integration of these two components permits for consistent information trade, guaranteeing real-time perceivability into mechanical forms. By empowering superior communication, PLC-HMI integration upgrades efficiency, minimizes blunders, and gives a user-friendly approach to mechanical automation.

Benefits of PLC and HMI Integration

One of the essential points of interest of coordination PLCs and HMIs is real-time information observing. Administrators can track framework execution and react to issues instantly. Moreover, progressed decision-making comes about from the capacity to analyze information patterns and distinguish potential wasteful aspects. Improved framework control permits administrators to make exact alterations, driving to higher exactness in mechanical forms. Another key advantage is diminished downtime, as prescient upkeep methodologies can be executed based on collected information. Finally, farther get to guarantees that administrators can screen and control gear from removed areas, moving forward operational flexibility.

Role of 140DDI85300 in Mechanical Information Collection

The 140DDI85300 is a advanced input module utilized in Modicon Quantum PLCs for collecting input signals from sensors and field gadgets. It plays a imperative part in mechanical mechanization by guaranteeing precise information securing and consistent communication between PLCs and HMIs. The module is outlined to handle different advanced inputs, making it a profitable component for large-scale robotization projects.

Features of the 140DDI85300

The 140DDI85300 module offers high-speed information procurement, empowering real-time observing of computerized signals. It bolsters numerous input channels, permitting it to handle assorted applications inside mechanical mechanization. Solid execution guarantees reliable information collection, contributing to exact control and observing of mechanical forms. Furthermore, its consistent HMI integration gives real-time visualization of input signals, making it less demanding for administrators to translate and react to changes in framework behavior.

Role of 140CRA21120 in Mechanical Communication

The 140CRA21120 is a Inaccessible I/O Connector Module that encourages communication between PLCs and farther I/O gadgets. It guarantees consistent information transmission, making it an fundamental component for large-scale mechanical robotization frameworks. This module plays a pivotal part in growing framework capabilities without requiring over the top wiring, in this manner disentangling establishment and maintenance.

Key Benefits of the 140CRA21120

The 140CRA21120 gives improved information communication, empowering real-time information exchange between PLCs and inaccessible I/O gadgets. Its versatility permits control frameworks to grow effectively whereas keeping up ideal execution. The module moreover contributes to progressed framework productivity by diminishing reaction time for information collection and prepare control. Moreover, its vigorous execution guarantees unwavering quality in requesting mechanical situations, making it an perfect choice for basic robotization applications.

Manufacturing Industry

PLC and HMI integration makes a difference producers track generation rates, machine status, and quality control in genuine time, driving to progressed efficiency. By giving moment criticism, administrators can make alterations that improve item consistency and decrease waste.

Power Plants

Power era offices utilize PLC-HMI integration to screen voltage levels, vitality dissemination, and framework deficiencies, guaranteeing smooth operation. Real-time cautions permit for speedy mediation, avoiding expensive disturbances in control supply.

Water Treatment Plants

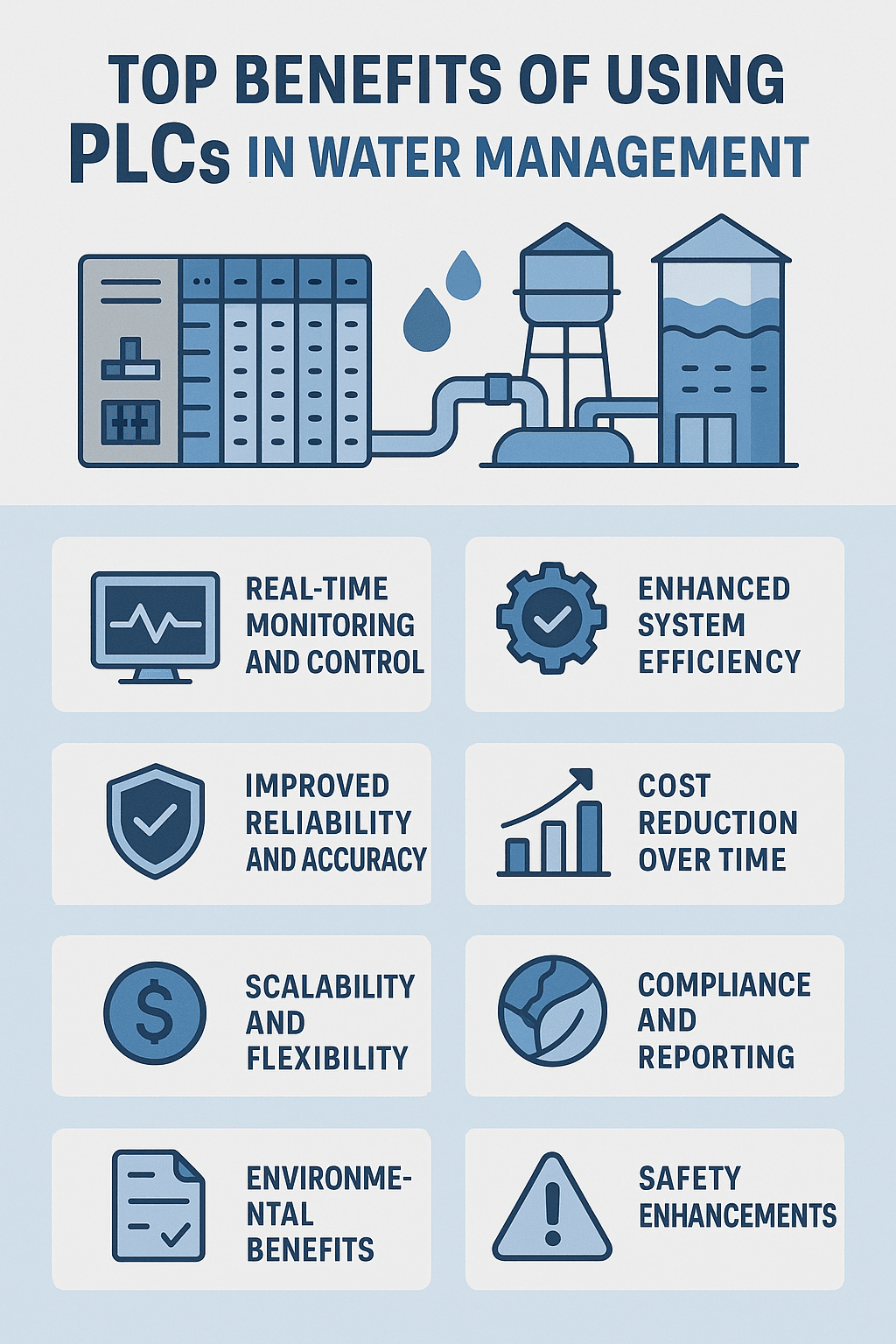

HMIs show information collected from PLCs with respect to water levels, chemical dosing, and filtration forms, guaranteeing compliance with administrative measures. Administrators can proficiently alter settings to keep up water quality and optimize treatment processes.

Oil and Gas Industry

In oil refineries and penetrating operations, PLCs and HMIs work together to screen pipeline weight, temperature, and security alarms. By giving nonstop observing, potential risks can be recognized and relieved some time recently they lead to failures.

Automotive Industry

Automated get together lines, automated welding, and quality control forms depend on PLC and HMI integration to guarantee effectiveness and consistency. These frameworks empower producers to optimize generation speed whereas keeping up high-quality standards.

Future Patterns in PLC and HMI Integration

Cloud-Based Mechanical Automation

The integration of cloud computing with PLCs and HMIs permits businesses to get to real-time information from anyplace, making strides adaptability and framework administration. Cloud-based arrangements empower inaccessible diagnostics and prescient support, decreasing operational costs.

AI and Machine Learning in Information Analysis

Future HMIs will coordinated AI-driven analytics to foresee machine disappointments and optimize mechanical forms utilizing verifiable information. These cleverly frameworks will give suggestions for handle changes, improving proficiency and lessening downtime.

Edge Computing for Quicker Processing

Edge computing empowers PLCs and HMIs to handle information closer to the source, decreasing idleness and moving forward reaction times. This approach upgrades framework execution and guarantees real-time control in basic applications.

Cybersecurity Enhancements

As mechanical systems ended up more associated, cybersecurity measures will play a significant part in ensuring PLC-HMI frameworks from cyber dangers. Secure communication conventions and encryption strategies will be basic to protect touchy mechanical data.

FAQs

How does PLC and HMI integration move forward mechanical automation?

PLC and HMI integration upgrades mechanical robotization by giving real-time information checking, making strides operational productivity, and empowering superior control over forms. Administrators can make educated choices rapidly, lessening downtime and expanding efficiency. What businesses advantage the most from PLC and HMI integration?

Industries such as fabricating, control plants, water treatment, oil and gas, and car generation advantage altogether from PLC and HMI integration. These frameworks offer assistance streamline forms, progress security, and optimize productivity in mechanized environments.

Can PLC and HMI integration offer assistance with prescient maintenance?

Yes, PLC and HMI integration bolsters prescient upkeep by collecting and analyzing real-time information. This permits administrators to distinguish potential issues early and perform upkeep some time recently disappointments happen, diminishing unforeseen downtime and repair costs.

What security measures ought to be executed in PLC and HMI systems?

To ensure PLC and HMI frameworks from cyber dangers, businesses ought to execute solid confirmation conventions, secure arrange associations, standard program overhauls, and firewall assurance. Utilizing encryption and limiting get to to authorized staff can encourage upgrade security.

Conclusion

The integration of PLCs and HMIs altogether improves mechanical information collection and handle control. Components like the 140DDI85300 advanced input module and the 140CRA21120 farther I/O connector guarantee consistent information securing and communication. As businesses move towards computerized change, headways in cloud computing, AI, and cybersecurity will assist revolutionize mechanical mechanization, making data-driven decision-making more effective and solid.