PLCs in Construction and Infrastructure Automation for Safety and Efficiency

The construction and structure diligence have seen significant advancements in robotization, leading to advancements in both safety and effectiveness. Programmable sense regulators (PLCs) are at the heart of this metamorphosis, enabling the robotization of complex processes, icing perfection, and enhancing overall productivity. This composition delves into the part of PLCs in construction and structure robotization, fastening on the significance of specific PLC models similar to the 1756-TBCH and XBTP022010 in enhancing safety and functional effectiveness.

The part of PLCs in Construction and structure robotization

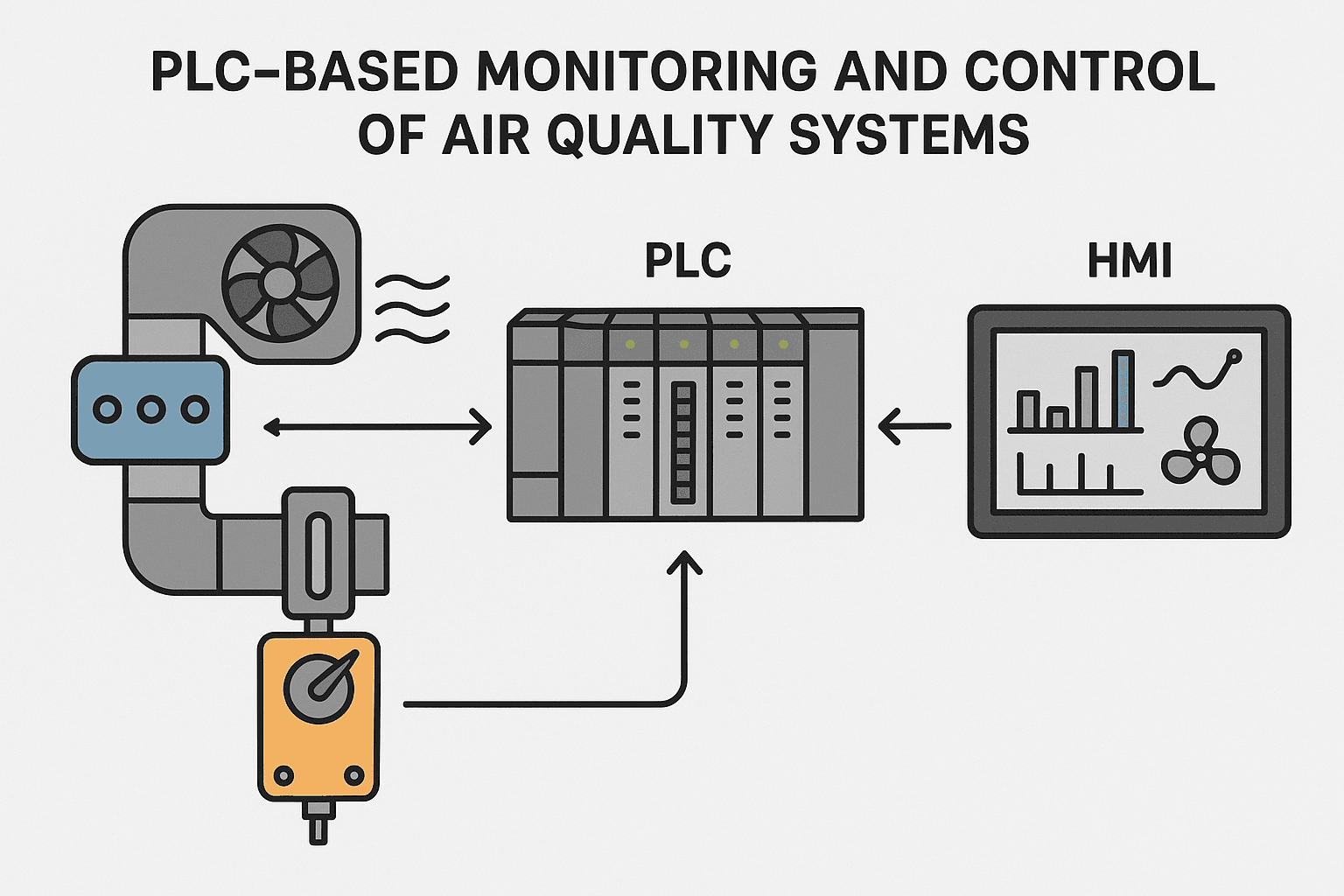

PLCs, integral factors of artificial robotization, are extensively used in the construction and structure sectors. Their primary function is to control ministry, processes, and systems with high trustability and perfection. PLCs are capable of covering multiple inputs and labors, automating tasks, and ensuring that operations are carried out efficiently.

In construction, PLCs can be employed for the robotization of cranes, conveyor belts, and other heavy machinery used in construction spots. For structure, they’re used in the operation of business systems, public transportation, and water treatment installations. The preface of PLCs in this diligence has been transformative in terms of safety and functional effectiveness.

Enhanced Safety with PLC Integration

Safety is consummate in both construction and structure systems, where implicit hazards and pitfalls are frequently present. PLCs contribute to safety by automating processes, reducing the chances of mortal error, and icing that operations cleave to predefined safety norms. They can be programmed with safety protocols and exigency arrest procedures to cover workers and the girding terrain.

For example, PLCs can cover temperature, pressure, and other critical parameters, driving admonitions or automatic shutdowns when values exceed safe limits. These systems are essential in avoiding accidents in dangerous surroundings, similar as during the operation of heavy machinery or the operation of high-pressure systems.

perfecting functional effectiveness with PLCs

PLCs are critical in perfecting the functional effectiveness of construction and structure systems. These systems automate tasks that would else bear significant homemade labor and time. They optimize product schedules, enhance resource allocation, and streamline workflows. Also, PLCs can cover the performance of outfits in real-time, relating inefficiencies and malfunctions before they become critical issues.

For illustration, PLCs in conveyor systems can acclimate pets automatically grounded on cargo conditions, icing a nonstop inflow of accoutrements and reducing time-out. In structure, they can optimize the operation of water pumps, business lights, or elevators to minimize energy consumption while maintaining high situations of service.

Key PLC Models 1756-TBCH and XBTP022010

Two specific models of PLCs that are vital in the robotization of construction and structure processes are the 1756-TBCH and XBTP022010. These models offer unique capabilities that make them ideal for complex construction and structure operations.

1756-TBCH Compact and Effective Control for Construction operations

The 1756-TBCH is a largely regarded module in Allen- Bradley’s ControlLogix PLC system, known for its trustability and scalability. This model is designed to give high-speed communication and control for artificial operations, making it an excellent choice for construction robotization.

Advantages of the 1756-TBCH in Construction

High-Speed Communication With its capability to manage large volumes of data snappily, the 1756-TBCH facilitates real-time control and monitoring of outfit on construction spots. This results in better safety and faster decision-making.

flawless Integration It integrates well with other PLCs and artificial systems, making it easier to automate colorful processes on a construction point, from material running to crane operations.

continuity The rugged nature of the 1756-TBCH makes it ideal for the grueling conditions of construction spots, including exposure to dust, climate, and extreme temperatures.

XBTP022010 Optimized for structure robotization

The XBTP022010 is another PLC model known for its versatility and robustness in robotization tasks, particularly in structure systems. This model is extensively used in sectors similar to water treatment, public transportation, and energy operations.

Benefits of the XBTP022010 for structure

Effective Resource Management The XBTP022010 is designed to automate and optimize the operation of structure systems, including energy operation and business control. It can cover and acclimate systems in real-time to ensure maximum effectiveness and minimum resource destruction.

Advanced Communication Protocols The model supports a variety of communication protocols, which makes it adaptable to different structure systems. It ensures smooth communication between biases, allowing for more precise control of systems like water pumps, sewage systems, and transportation networks.

Scalability The XBTP022010 is scalable, making it suitable for both small-scale and large structure systems. It can be fluently expanded as design conditions grow, icing long-term value for structure robotization.

The Future of PLCs in Construction and structure

The integration of PLCs into construction and structure robotization is just the morning. With advancements in artificial intelligence (AI), machine literacy, and IoT (Internet of Effects), the future of PLCs holds indeed further promise. These technologies can further enhance the capabilities of PLCs, enabling prophetic conservation, smarter resource operation, and indeed lesser effectiveness in the robotization of construction and structure processes.

As these technologies evolve, PLCs like the 1756-TBCH and XBTP022010 will continue to play a critical part in advancing robotization systems, improving safety, reducing costs, and perfecting overall productivity in construction and structure systems.

Conclusion

PLCs are necessary in contemporary construction and structure robotization systems. They not only ameliorate functional effectiveness but also contribute significantly to safety, reducing pitfalls and precluding accidents. With important models like the 1756-TBCH and XBTP022010, diligence can calculate on advanced control systems to streamline operations, boost productivity, and ensure that complex systems run easily. As robotization technologies continue to advance, PLCs will remain at the van, driving invention and progress in construction and structure diligence worldwide.