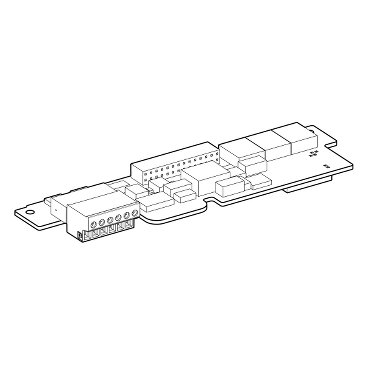

VW3A3407 – encoder interface card, Altivar

Original price was: $193.00.$149.00Current price is: $149.00.

The VW3A3407 is an encoder interface card that allows seamless connection of rotary encoders to Altivar variable frequency drives.

2 in stock

Free shipping on orders over $5000!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

| range of product | Altivar. |

|---|---|

| product or component type | Encoder interface card. |

| range compatibility | Altivar 61Q. Altivar 71Q. Altivar 71. Altivar 61. Altivar Lift. |

| discrete output type | Push-pull |

| [Us] rated supply voltage | 24 V DC (voltage limits: 20…30 V). |

| number of pulses per revolution | 10000 for ATV71H……383. 5000 for all ATV61 drives. 5000 for ATV71H…M3. 5000 for ATV71H…M3X. 5000 for ATV71H…N4. |

| maximum supply current | 0.175 A. |

|---|---|

| protection type | Overload protection. Short-circuit protection. |

| maximum cable distance between devices | 500 m. |

| maximum operating frequency | 300 kHz. |

| input signal | A B Compliment of A. Compliment of B/AB/A. |

| input impedance | 1000 Ohm. |

| voltage state 0 guaranteed | <= 1.5 V. |

| voltage state 1 guaranteed | > 11.5…< 25 V. |

| electrical connection | Terminal, connection capacity: 0.2 mm² (AWG 24). <500 m cable length, encoder, 100 mA at 14 V. |

| Unit Type of Package 1 | PCE. |

|---|---|

| Number of Units in Package 1 | 1. |

| Package 1 Weight | 148.0 g. |

| Package 1 Height | 7.5 cm. |

| Package 1 width | 17 cm. |

| Package 1 Length | 23 cm. |

| Unit Type of Package 2 | S03. |

| Number of Units in Package 2 | 7. |

| Package 2 Weight | 1.503 kg. |

| Package 2 Height | 30 cm. |

| Package 2 width | 30 cm. |

| Package 2 Length | 40 cm. |