Temperature-Triggered Air Cooler Control Using PLC and Sensors

In moment’s period of artificial robotization, maintaining optimal temperature in artificial and marketable surroundings is pivotal. Overheating can lead to system failures, outfit damage, and reduced functional effectiveness. One smart result to this problem is a Temperature- touched off Air Cooler Control System using Programmable Logic regulators( PLC) and detectors. This system automates cooling grounded on real- time temperature data, icing effective energy use and dependable performance.

The Need for Automated Cooling Systems

Homemade control of air cooling units is hamstrung and frequently leads to energy destruction. Especially in large- scale diligence, where temperature variations are frequent, mortal intervention for temperature regulation becomes impracticable. Automating the air cooling process using PLCs not only improves functional effectiveness but also minimizes mortal error, reduces time-out, and prolongs outfit life.

How the System Works

A Temperature- touched off Air Cooler Control System integrates several factors, primarily temperature detectors, a PLC, and an HMI( Human Machine Interface). Let’s explore how these corridor interact.

Part of Temperature Detectors

The system starts with temperature detectors strategically placed in the terrain that needs cooling. These detectors continuously cover the ambient temperature and shoot data to the PLC. Generally used temperature detectors include thermocouples and resistance temperature sensors( RTDs) due to their delicacy and continuity.

PLC as the Control Unit

The Programmable Logic Controller( PLC) acts as the brain of the system. It receives temperature data from the detectors and, grounded onpre-programmed sense, decides whether to turn the air cooler on or out. The sense generally involves setting threshold values. For illustration, if the temperature exceeds 30 °C, the PLC sends a signal to spark the air cooler. Once the temperature drops below a defined limit, say 25 °C, it deactivates the cooler.

This on- off control medium ensures that the terrain stays within a specific temperature range, perfecting both comfort and energy effectiveness.

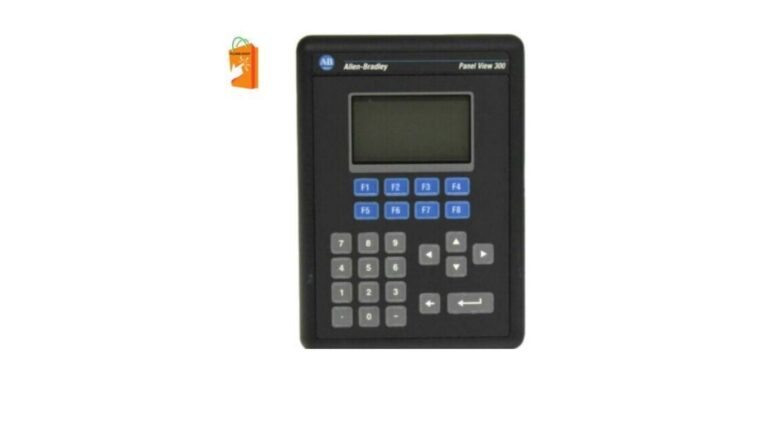

HMI for stoner Interaction

An HMI panel is pivotal for real- time monitoring and system commerce. Drivers can view live temperature readings, system status, and modify settings through the HMI. Two extensively used HMI models in this setup are the HMIGTO2310 and the HMIGTO5310, both from Schneider Electric.

HMIGTO2310 and HMIGTO5310 in Air Cooler Control

Overview of HMIGTO2310

The HMIGTO2310 is a compact yet important HMI designed for machine- position interface needs. It features a 5.7- inch touchscreen display, Ethernet connectivity, and is compatible with colorful artificial PLCs. In the temperature- touched off cooler control system, it serves as the stoner-friendly interface through which drivers can cover temperature situations, manually override controls, and view fault logs.

Features of HMIGTO5310

The HMIGTO5310 is a more advanced HMI model with a larger 10.4- inch screen, advanced resolution, and enhanced communication anchorages including USB, RS232/ RS485, and Ethernet. It offers a more detailed visualization, making it ideal for systems that bear more complex monitoring. In air cooler control, the HMIGTO5310 is salutary for displaying temperature trends over time, setting temperature thresholds graphically, and managing multiple cooler units contemporaneously.

Advantages of Using PLC and Sensors for Cooler Control

Energy Efficiency

The automated system ensures that the air cooler runs only when necessary, leading to significant energy savings. This is particularly important in manufacturing units where energy consumption is a major concern.

Precision and Accuracy

Using digital detectors and PLCs improves the perfection of temperature regulation. The system reacts incontinently to temperature changes, maintaining an optimal terrain constantly.

Reduced mortal Intervention

robotization minimizes the need for homemade checks and interventions, therefore reducing the threat of crimes and labor costs.

Easy Integration with SCADA

The system can be fluently integrated with SCADA( Supervisory Control and Data Acquisition) systems for remote monitoring and advanced analytics.

Operation Areas

This technology is largely protean and can be applied in

- Artificial robotization To maintain optimal working temperatures for ministry and processes.

- Data Centers Where indeed slight temperature increases can lead to performance declination.

- Glasshouses To automate cooling for factory health.

- Marketable structures For smart HVAC control that adapts to environmental changes.

Perpetration Considerations

When designing and planting a temperature- touched off cooler control system, consider the following

- Sensor Placement insure detectors are installed in locales that represent true ambient conditions.

- PLC Programming Logic should regard for temperature hysteresis to help frequent on- off cycling.

- HMI Configuration Customize screen layouts for intuitive use by drivers.

Device comity Make sure HMIs like HMIGTO2310 or HMIGTO5310 are compatible with the named PLC and detectors.

Conclusion

The integration of PLCs, detectors, and advanced HMIs like HMIGTO2310 and HMIGTO5310 into air cooler control systems revolutionizes temperature operation. These systems are smarter, briskly, and more dependable than traditional homemade styles. Whether you are managing an artificial installation or a high- tech garçon room, enforcing a temperature- touched off air cooler control system ensures harmonious performance, energy savings, and a streamlined conservation process.