The Role of HMIs in PLC-Based Control Systems

Introduction

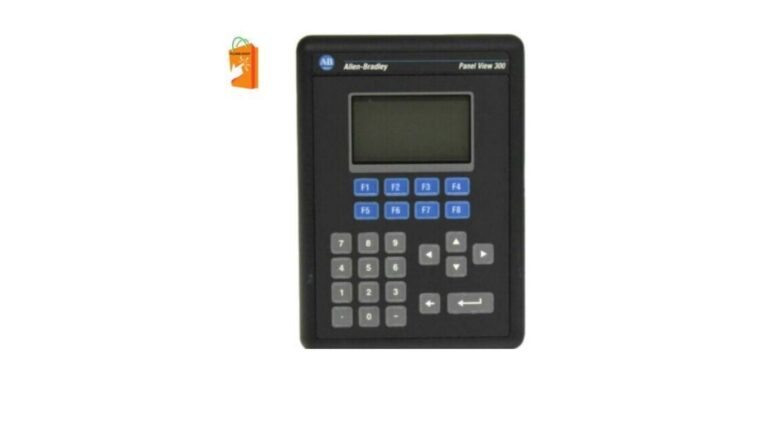

Human-Machine Interfacing (HMIs) play a vital part in PLC-based control frameworks by giving an intelligently stage for administrators to screen and control mechanical forms. HMIs improve operational productivity, minimize downtime, and move forward by and large framework performance.

Understanding HMIs in PLC-Based Systems

HMIs are basic components in cutting edge mechanical mechanization, empowering administrators to visualize and associated with complex forms. They encourage consistent communication between people and Programmable Rationale Controllers (PLCs), guaranteeing exact control over apparatus and hardware. HMIs change over complex machine forms into user-friendly graphical interfacing, permitting administrators to make speedy and educated decisions.

Key Highlights of HMIs

- Graphical Show: HMIs utilize instinctive touchscreens, graphical representations, and intelligently components to make observing more efficient.

- Data Logging and Detailing: Real-time information logging makes a difference administrators track patterns, distinguish flaws, and make strides performance.

- Alarms and Notices: HMIs caution administrators to framework disappointments, temperature variances, and other basic conditions.

- Remote Get to: With cutting edge network highlights, administrators can get to HMIs from inaccessible areas for diagnostics and framework monitoring.

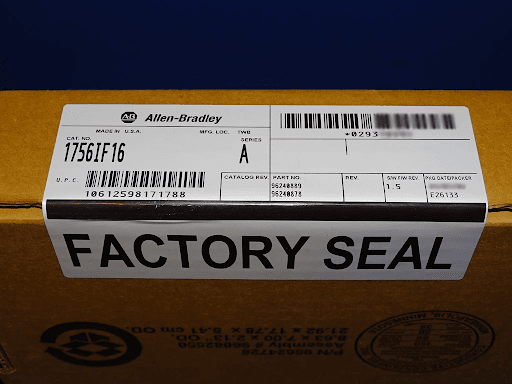

Role of the 140ACO02000 in HMI-PLC Communication

The 140ACO02000 is an analog yield module utilized in Modicon Quantum PLCs. It plays a basic part in controlling analog gadgets such as actuators, variable speed drives, and mechanical controllers. When coordinates with an HMI, it permits real-time alterations to prepare factors, guaranteeing smooth and productive operations.

How the 140ACO02000 Improves HMI Functionality

Precision Control: The module gives exact analog yield signals for exact prepare control.

Flexibility: It bolsters different yield ranges, making it consistent with distinctive mechanical devices.

Reliability: Planned for high-performance applications, it guarantees steady operations in requesting environments.

How the 140ACI03000 Improves HMI Functionality

The 140ACI03000 is an analog input module that collects real-time information from sensors and transmits it to the PLC. This information is at that point shown on the HMI, permitting administrators to make educated choices based on live handle factors. By coordination this module with an HMI, businesses can accomplish higher accuracy in checking temperature, weight, and other basic parameters.

Benefits of Utilizing the 140ACI03000

High Exactness: Guarantees exact estimation of analog inputs for basic handle monitoring.

Multiple Input Channels: Able of dealing with different sensor inputs simultaneously.

Enhanced Framework Diagnostics: Makes a difference distinguish flaws in associated sensors and instrumentation.

Applications of HMIs in PLC-Based Control Systems

Manufacturing Industry

In fabricating plants, HMIs play a crucial part in overseeing generation lines, checking machine conditions, and guaranteeing quality control. Administrators can track item stream, control machine speeds, and react to issues instantly.

Power Era and Distribution

HMIs offer assistance control control era units, optimize vitality conveyance, and guarantee smooth operations of control frameworks. They give real-time visualization of electrical parameters and offer assistance anticipate outages.

Water Treatment Plants

Water treatment offices depend on HMIs to screen filtration, chemical dosing, and water levels. HMIs show pH levels, weight readings, and stream rates, guaranteeing compliance with natural regulations.

Oil and Gas Industry

In the oil and gas segment, HMIs help in pipeline checking, boring operations, and refinery control. They give basic security cautions and permit inaccessible control of perilous processes.

Automotive Industry

Automotive fabricating includes broad robotization, where HMIs offer assistance in mechanical get together, transport belt control, and quality testing. They move forward proficiency and diminish the chance of human errors.

Advantages of Utilizing HMIs in PLC-Based Control Systems

HMIs upgrade mechanical forms by diminishing manual mediation, expanding framework responsiveness, and making strides effectiveness. They give real-time information visualization, alert notices, and verifiable information logging, making a difference businesses optimize execution and safety.

Improved Operational Efficiency

HMIs streamline mechanical mechanization by lessening manual intercession and upgrading framework responsiveness. Administrators can effectively alter machine settings, lessening generation downtime and moving forward by and large efficiency.

Increased Security and Reliability

By showing real-time alerts and cautions, HMIs offer assistance avoid framework disappointments and guarantee a secure working environment. Security interlocks and crisis shutdowns can be activated immediately through HMI interfaces.

Cost Reserve funds and Decreased Downtime

Automated observing and control decrease upkeep costs and minimize unforeseen downtime, driving to expanded efficiency. With prescient upkeep highlights, businesses can distinguish potential disappointments some time recently they occur.

Remote Checking and Control

Modern HMIs are prepared with IoT (Web of Things) capabilities, permitting administrators to control and screen mechanical forms from inaccessible areas. This progresses adaptability, decreases travel costs, and improves in general management.

Scalability and Customization

HMIs can be customized based on the particular needs of an industry. Whether controlling a single generation line or an whole manufacturing plant, HMIs offer adaptable arrangements that develop with commerce demands.

Challenges in Actualizing HMIs

High Starting Investment

Implementing progressed HMI arrangements requires a noteworthy forthright speculation in equipment, computer program, and preparing. In any case, the long-term benefits exceed the starting costs.

Cybersecurity Risks

As HMIs gotten to be more associated through cloud administrations and farther get to, they are vulnerable to cyber dangers. Businesses must execute vigorous cybersecurity measures to secure their control frameworks from cyber-attacks.

Complex Integration with Bequest Systems

Many mechanical offices still work more seasoned PLCs and control frameworks, making HMI integration challenging. Appropriate arranging and retrofit arrangements are required to guarantee consistent compatibility.

Future of HMIs in Mechanical Automation

Artificial Insights (AI) and Machine Learning Integration

Future HMIs will coordinated AI and machine learning calculations to give prescient analytics, empowering administrators to take proactive activities some time recently disappointments occur.

Augmented Reality (AR) and Virtual Reality (VR) Interfaces

AR and VR-enabled HMIs will revolutionize mechanical preparing, diagnostics, and farther back. Administrators will be able to visualize complex frameworks in 3D environments.

Cloud-Based HMIs

Cloud innovation will empower real-time information get to from anyplace in the world, permitting businesses to execute keen manufacturing plant arrangements with worldwide connectivity.

Edge Computing for Speedier Processing

With edge computing, HMIs will prepare information closer to the source, diminishing idleness and moving forward real-time decision-making.

Conclusion

The integration of HMIs in PLC-based control frameworks essentially makes strides mechanical computerization. Modules like 140ACO02000 and 140ACI03000 improve communication between the HMI and PLC, empowering effective checking and control. As businesses move towards advanced change, the part of HMIs will proceed to extend, guaranteeing optimized execution, framework unwavering quality, and improved decision-making capabilities.