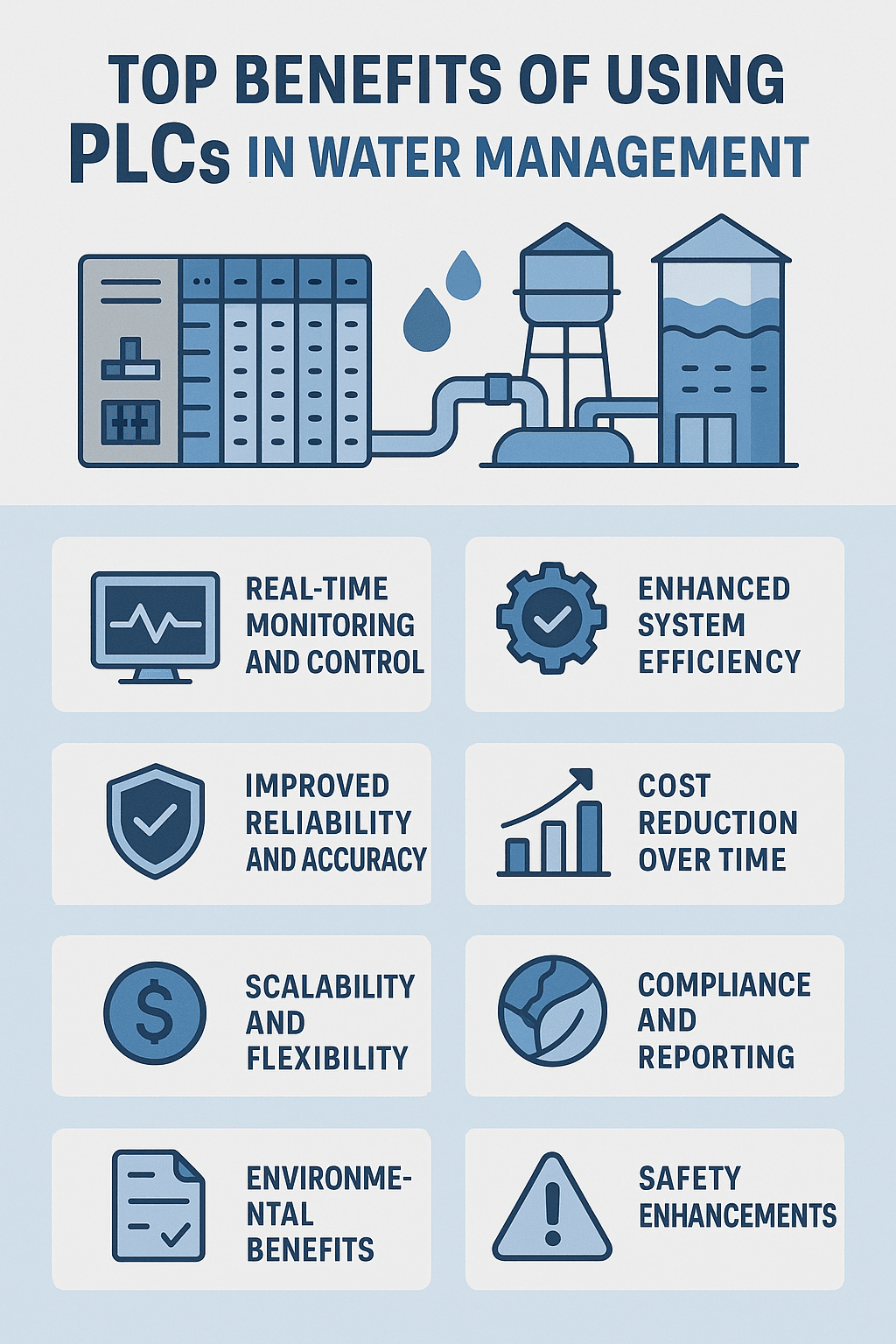

Top Benefits of Using PLCs in Water Management

In today’s modern water management systems, precision, automation, and reliability are essential. One of the most effective technologies enabling this is the Programmable Logic Controller (PLC). Devices like BMEAHO0412 and BMXP3420102 are examples of PLC modules that contribute significantly to efficient water control systems. These controllers help streamline processes such as water purification, distribution, monitoring, and wastewater treatment, making them an indispensable part of any advanced water infrastructure.

Below, we’ll explore the top benefits of using PLCs in water management systems and how specific models like BMEAHO0412 and BMXP3420102 can enhance performance.

Understanding PLCs in Water Management

What is a PLC?

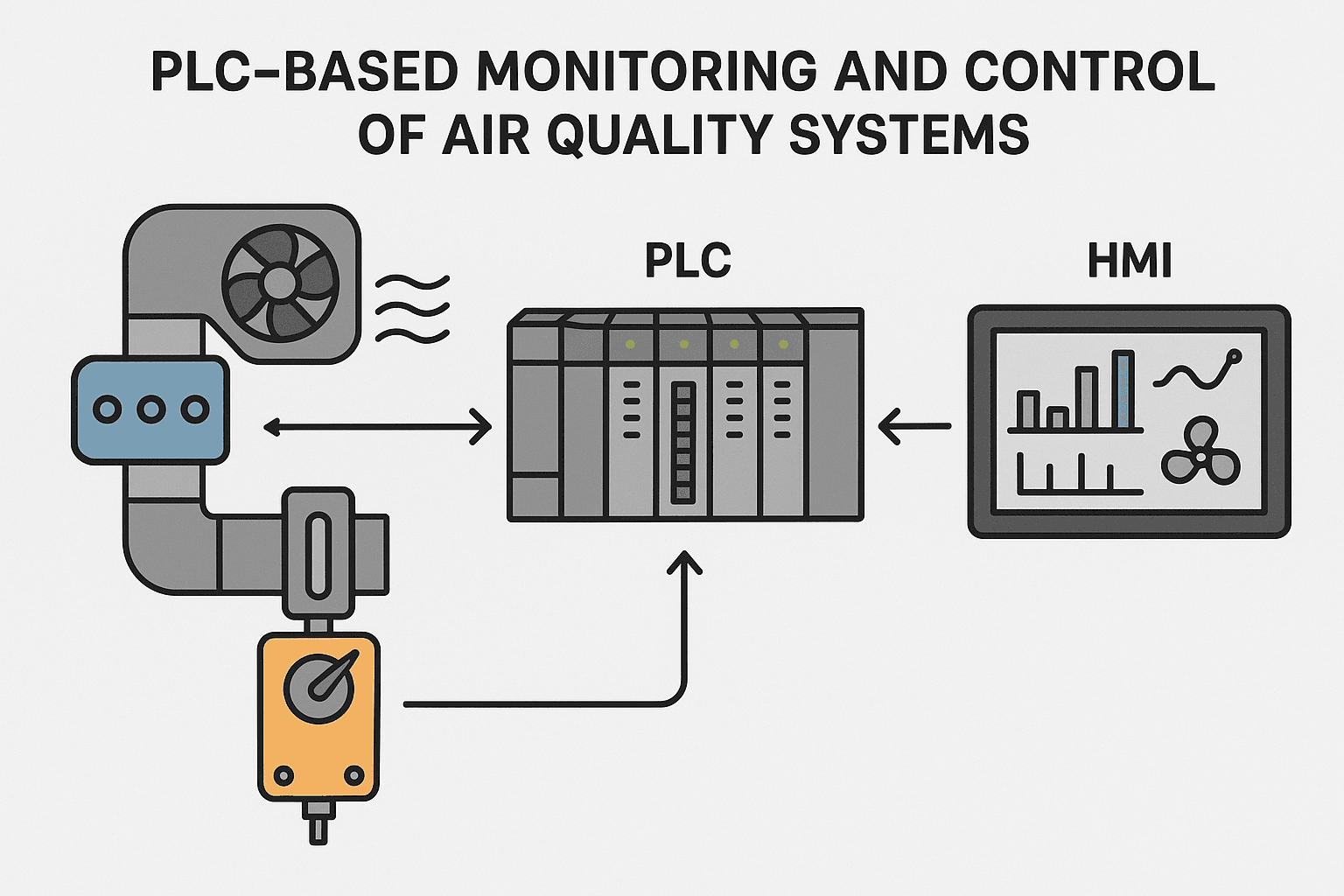

A PLC, or Programmable Logic Controller, is a digital computer specifically designed for industrial applications. It continuously monitors inputs and makes decisions based on programmed logic to control outputs. In water systems, this means automating tasks like pump control, valve operation, pressure monitoring, and system diagnostics.

Why Water Systems Need PLCs

Water management involves complex tasks requiring precision and quick decision-making. PLCs allow engineers to program specific responses to changes in pressure, flow, chemical levels, or pump performance. This not only improves efficiency but also ensures the reliability of operations.

1. Real-Time Monitoring and Control

Instant Decision Making

PLCs like the BMEAHO0412 module offer real-time processing capabilities. This allows for instant reaction to changes in system inputs such as water pressure or tank levels, ensuring that operations remain within safe and efficient parameters.

Remote Access and Visualization

Modern PLCs integrate with SCADA (Supervisory Control and Data Acquisition) systems, enabling operators to monitor and control the system remotely. This real-time data visualization helps identify problems before they escalate.

2. Enhanced System Efficiency

Energy Savings

PLCs reduce energy consumption by optimizing pump and valve operations. For instance, BMXP3420102 can be programmed to operate pumps during off-peak energy hours or according to demand, minimizing unnecessary usage.

Process Optimization

With detailed programming, PLCs allow for fine-tuned operations. This means only the exact amount of water needed is pumped or treated, avoiding waste and improving efficiency.

3. Improved Reliability and Accuracy

Consistent Operation

Manual systems are prone to human error and inconsistent performance. PLCs eliminate this by ensuring that all processes follow the same programmed logic every time.

Fault Detection and Alarms

Modules like BMEAHO0412 support advanced fault detection and alarm systems, immediately notifying operators of any irregularities such as pump failures or abnormal flow rates. This drastically reduces downtime.

4. Cost Reduction Over Time

Reduced Maintenance Costs

PLC systems allow for predictive maintenance. Sensors and programs can track equipment usage and performance, alerting operators before major breakdowns occur. This minimizes the need for emergency repairs and extends equipment lifespan.

Lower Operational Costs

By automating routine processes and improving energy efficiency, PLCs cut down operational costs. Devices like BMXP3420102 can be integrated with energy monitoring tools to further analyze and reduce consumption.

5. Scalability and Flexibility

Easy Integration with Existing Systems

PLCs are modular, meaning they can be easily integrated into existing systems. For instance, both BMEAHO0412 and BMXP3420102 are designed for easy expansion and compatibility with various I/O modules and communication protocols.

Adaptable Programming

If the water management requirements change, PLCs can be reprogrammed without needing to replace the hardware. This adaptability makes PLCs future-proof investments for growing municipalities and industrial setups.

6. Compliance and Reporting

Data Logging and Record Keeping

Water treatment facilities often need to report data to regulatory agencies. PLCs automatically log operational data such as chemical dosages, flow rates, and tank levels, making compliance easier and more accurate.

Audit Trails and Quality Control

With PLCs, every change in the system is recorded, creating a detailed audit trail. This not only helps in regulatory compliance but also ensures consistent water quality standards are maintained.

7. Environmental Benefits

Waste Reduction

Automated control leads to more precise chemical dosing and water use, reducing environmental impact. Overdosing or underdosing chemicals is minimized, leading to safer discharge into the environment.

Leak Detection and Response

PLCs help detect leaks quickly through real-time pressure and flow monitoring. Quick detection reduces water waste and potential damage to infrastructure.

8. Safety Enhancements

Emergency Shutdown Procedures

PLCs can be programmed with emergency shutdown logic, preventing damage in case of pressure spikes, contamination, or equipment failure. This ensures the safety of both the system and personnel.

System Redundancy and Backup

Advanced PLCs like BMXP3420102 support redundant configurations. In case of failure, the backup system kicks in, ensuring uninterrupted operation of critical water systems.

Conclusion

PLCs have transformed the water management industry by offering automation, efficiency, and precision. With the integration of powerful modules such as BMEAHO0412 and BMXP3420102, water systems can operate smarter, faster, and more reliably than ever before. From real-time monitoring to regulatory compliance and environmental responsibility, the benefits of PLCs are extensive and essential for modern infrastructure.

FAQs

Q1: What is the function of a PLC in a water management system?

A PLC automates control processes such as pump operation, valve timing, chemical dosing, and fault detection to ensure efficient and safe water management.

Q2: How does the BMEAHO0412 module help in water automation?

BMEAHO0412 is an I/O module that provides high-speed data processing for precise control over sensors and actuators in water systems.

Q3: What are the benefits of using BMXP3420102 in water treatment?

BMXP3420102 offers powerful processing, scalability, and advanced networking features, making it ideal for complex water treatment and distribution systems.

Q4: Can PLCs help reduce energy consumption in water plants?

Yes, PLCs optimize operations based on real-time data, which reduces unnecessary pump activity and power use, thereby lowering energy consumption.

Q5: Are PLCs suitable for small-scale water systems?

Absolutely. PLCs are scalable and can be used in small community systems as well as large municipal or industrial setups.