Understanding PLC Hardware and Its Key Components

Programmable logic controller( PLCs) are essential in the ultramodern artificial geography, serving as the brain behind robotization and control systems in manufactories, shops, and other complex surroundings. A PLC is a digital computer designed for artificial operations to automate processes and ministry. Understanding PLC tackle and its crucial factors is pivotal for masterminds and technicians who work with robotization systems. This composition will explore the critical rudiments of PLC tackle and highlight specific models, similar as TWDLCAE40DRF and SXWAUTSVR10001, which represent popular PLC results.

Key Components of PLC Hardware

PLCs are composed of several crucial factors that work together to execute control processes. These factors insure the system can manage inputs, perform sense processing, and control labors efficiently. The primary factors of a PLC are as follows

1. Central Processing Unit( CPU)

The CPU is the heart of the PLC system. It processes all the control instructions and handles the communication between colorful modules. The CPU reads the input signals, executes the sense defined in the program, and sends affair signals to control machines or processes. The processing speed, memory capacity, and communication capabilities of the CPU determine the overall performance of the PLC system.

2. Input and Affair Modules( I/ O Modules)

Input modules admit signals from detectors and other bias, similar as temperature detectors, pressure detectors, or limit switches. These inputs are also reused by the CPU. Affair modules, on the other hand, shoot control signals to selectors like motors, faucets, and other ministry. The I/ O modules are pivotal for connecting the PLC to the physical world.

3. Power Supply

The power force ensures that the PLC receives the necessary electrical energy to serve. It converts the input voltage into a stable force voltage for the CPU and other factors. Power inventories are available in different configurations depending on the PLC model and its operation.

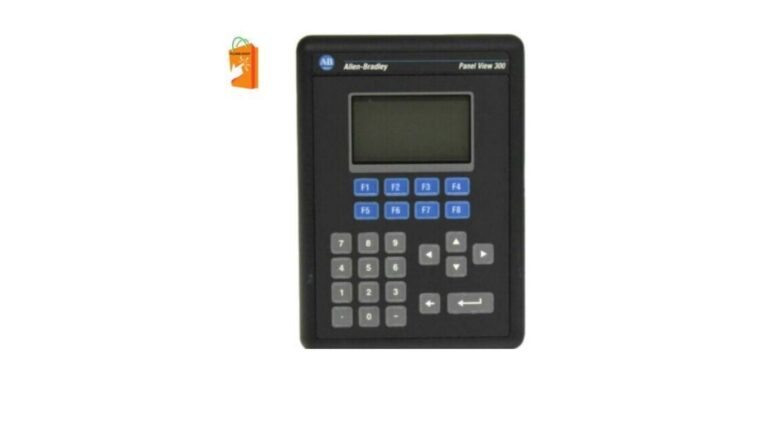

4. Communication Anchorages

PLCs frequently need to communicate with other bias, similar as SCADA systems, HMI panels, or other PLCs. Communication anchorages allow data exchange via colorful protocols similar as Ethernet, Modbus, Profibus, and others. The vacuity of communication options helps in integrating the PLC into larger artificial networks.

5. Programming Device

A programming device is used to develop and upload the control sense into the PLC. This could be a laptop or desktop computer with specific software for programming, like Siemens Step 7, Allen Bradley’s RSLogix, or Schneider Electric’s EcoStruxure. The programming device is connected to the PLC via communication lines or wireless connections.

Exploring Specific PLC Models

TWDLCAE40DRF A Compact PLC result

The TWDLCAE40DRF is a specific model from the Twido series by Schneider Electric. This compact PLC is designed for small and medium robotization operations, where space and cost are critical considerations. Despite its small form factor, the TWDLCAE40DRF provides important processing capabilities with over to 40 I/ O points, making it suitable for colorful control and robotization tasks.

Crucial Features of TWDLCAE40DRF

Compact Design: Its small footmark allows for easy integration into limited spaces, making it ideal for lower machines or control closets.

Flexible I/ O Options: The model supports both digital and analog I/ O modules, making it protean for a wide range of operations.

Ease of Programming: It’s programmed using Schneider Electric’s SoMachine software, which offers a stoner-friendly interface and supports multiple programming languages.

The TWDLCAE40DRF: Supports Modbus communication for integration with other bias, enhancing its capability to fit into complex artificial networks.

Advanced Control and robotization

The SXWAUTSVR10001 is another model that fits into the order of advanced PLC systems, known for its high- position performance in robotization processes. This model provides exceptional functionality for larger systems, supporting further I/ O points and high- speed processing capabilities compared to compact models like the TWDLCAE40DRF.

Crucial Features

- High- Performance: CPU The SXWAUTSVR10001 is equipped with a fast processor that can handle complex control tasks and process data snappily.

- Extended I/ O Capacity: This model supports a lesser number of I/ O points, making it suitable for larger artificial surroundings where multiple detectors and selectors need to be controlled.

- Scalability: The SXWAUTSVR10001 can be expanded by adding further modules, which allows for the creation of customized robotization systems that gauge with business requirements.

Advanced Communication It’s designed with robust communication protocols, similar as Ethernet/ IP and Modbus TCP, enabling flawless integration with ultramodern robotization networks.

PLC Hardware Application Areas

PLCs have broad operations across colorful diligence, from manufacturing to energy operation. Some of the most common areas where PLC tackle is applied include

- Manufacturing robotization: PLCs control assembly lines, robotic arms, and other ministry in manufacturing shops.

- Energy and Utilities: PLCs are used in power shops and water treatment installations to control processes and maintain functional effectiveness.

- Structure robotization: In large structures, PLCs help control heating, ventilation, and air exertion( HVAC) systems, lighting, and security systems.

Transportation PLCs are involved in controlling automated gates, conveyor belts, and other transportation mechanisms in airfields, train stations, and storages.

Conclusion

PLCs are at the heart of robotization in ultramodern diligence. Their tackle factors, including the CPU, I/ O modules, power force, and communication anchorages, insure smooth operation and control of artificial processes. The TWDLCAE40DRF and SXWAUTSVR10001 are exemplifications of how PLC systems can vary in size, functionality, and performance to suit different robotization requirements. Whether for a compact system or a larger, more complex setup, understanding the crucial factors and the capabilities of specific PLC models is essential for erecting effective and dependable robotization results.