How Power Meters Can Save Your Factory from Power Glitches and Issues

Introduction

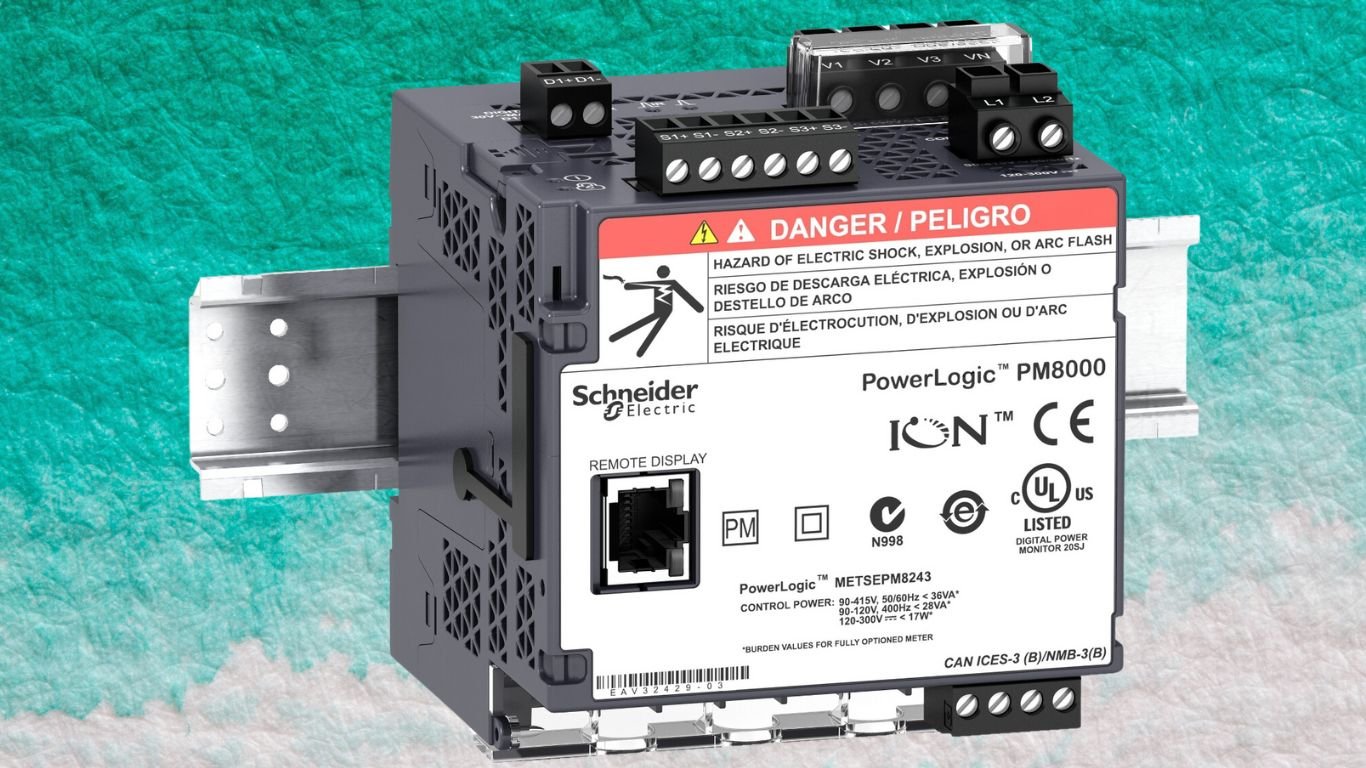

In today’s fast-paced industrial world, factories are heavily reliant on a stable and efficient power supply to ensure seamless operations. However, power glitches such as voltage sags, spikes, interruptions, and harmonic distortions can lead to costly downtime, equipment damage, and reduced efficiency. Power meters are the unsung heroes that can safeguard your factory from these power-related issues. Schneider Electric, a global leader in energy management, offers a range of advanced power meters that can significantly enhance your factory’s power management and operational resilience.

This article delves into how power meters help mitigate power glitches, explores the best Schneider Electric power meters available, and provides detailed insights into their features and benefits.

The Role of Power Meters in Addressing Power Glitches

1. Real-Time Monitoring and Alerts

Power meters continuously monitor electrical parameters such as voltage, current, frequency, and power factor. Real-time monitoring ensures that any anomalies in the power supply are detected instantly. Alerts can be sent to maintenance teams to take immediate corrective actions, preventing damage to sensitive equipment.

2. Power Quality Analysis

Power glitches often stem from poor power quality. Power meters provide detailed insights into power quality parameters, such as:

- Voltage Harmonics: These can cause overheating and malfunctioning of equipment.

- Voltage Sags and Swells: Can disrupt machinery operations.

- Power Factor: A low power factor increases energy costs.

By identifying these issues, factories can take steps to stabilize their power systems.

3. Energy Consumption Tracking

High energy consumption often indicates inefficiencies or faulty equipment. Power meters track energy usage across different sections of the factory, helping identify areas for energy optimization.

4. Preventive Maintenance

Data from power meters enables predictive and preventive maintenance by highlighting trends that indicate potential equipment failures. This reduces unplanned downtime and extends the lifespan of electrical assets.

5. Compliance with Standards

Many industries must comply with power quality standards to avoid penalties and maintain operational licenses. Power meters help ensure compliance by providing detailed reports and analysis.

Best Schneider Electric Power Meters for Your Factory

Schneider Electric’s range of power meters is designed to meet diverse industrial needs. Below are the top models that stand out for their advanced features and reliability:

1. Schneider Electric METSEPM5330

The METSEPM5330 is a high-performance power meter that offers comprehensive monitoring capabilities. It is ideal for applications requiring detailed energy consumption data.

Key Features:

- Monitors active, reactive, and apparent power.

- Advanced harmonic analysis for improved power quality.

- Supports Modbus communication for easy integration.

- Compact design for panel mounting.

Benefits:

- Enhances power quality management.

- Provides accurate energy consumption insights for cost-saving initiatives.

2. Schneider Electric METSEPM5560

This power meter is perfect for medium to large industrial setups. It offers advanced analytics and is equipped with Ethernet connectivity for remote monitoring.

Key Features:

- High-accuracy Class 0.2S energy measurements.

- Real-time monitoring of voltage, current, and power.

- Supports multiple communication protocols, including Modbus and Ethernet.

Benefits:

- Simplifies energy audits.

- Reduces downtime with predictive analytics.

3. Schneider Electric METSEPM5110

The METSEPM5110 is a budget-friendly option for factories looking to improve their power management without incurring high costs.

Key Features:

- Basic monitoring of electrical parameters.

- Simple installation and user-friendly interface.

- Compact and durable design.

Benefits:

- Cost-effective solution for smaller factories.

- Provides essential power monitoring capabilities.

4. Schneider Electric METSEPM89M2600

This advanced power meter is designed for factories requiring high-precision energy monitoring and control.

Key Features:

- Multi-tariff energy metering.

- Advanced load profile analysis.

- Built-in memory for data logging.

Benefits:

- Helps optimize energy usage patterns.

- Enables detailed analysis for operational efficiency.

5. Schneider Electric METSEPM8210

The METSEPM8210 is an all-rounder power meter that combines performance with ease of use. It is well-suited for factories of all sizes.

Key Features:

- Comprehensive monitoring of power parameters.

- Intuitive user interface with a backlit display.

- Compatible with multiple communication protocols.

Benefits:

- Improves overall power management.

- Reduces energy waste through precise monitoring.

6. Schneider Electric METSEPM5330-2

An upgraded version of the METSEPM5330, this model offers enhanced features for better power management.

Key Features:

- Extended data logging capabilities.

- Supports advanced communication protocols.

- Compact and robust design for industrial environments.

Benefits:

- Ideal for detailed energy audits.

- Helps identify and mitigate power quality issues.

Comparison Table

| Model | Key Features | Best For | Backlink |

|---|---|---|---|

| METSEPM5330 | Harmonic analysis, Modbus communication | Comprehensive monitoring | Explore METSEPM5330 |

| METSEPM5560 | High-accuracy, Ethernet connectivity | Medium to large factories | Explore METSEPM5560 |

| METSEPM5110 | Basic monitoring, cost-effective | Smaller factories | Explore METSEPM5110 |

| METSEPM89M2600 | Multi-tariff metering, load profile analysis | Precision energy management | Explore METSEPM89M2600 |

| METSEPM8210 | Comprehensive monitoring, user-friendly | All factory sizes | Explore METSEPM8210 |

| METSEPM5330-2 | Extended data logging, advanced protocols | Detailed energy audits | Explore METSEPM5330-2 |

How to Choose the Right Power Meter

Selecting the right power meter depends on the specific needs of your factory:

- Size of Operations: Larger factories may benefit from advanced models like the METSEPM5560, while smaller setups can opt for the METSEPM5110.

- Power Quality Concerns: If power quality is a major issue, choose a model with harmonic analysis capabilities, such as the METSEPM5330.

- Budget: For cost-effective solutions, consider the METSEPM5110 or METSEPM5330.

- Integration Needs: Ensure the power meter supports the required communication protocols for seamless integration with your existing systems.

Conclusion

Power meters are indispensable tools for factories aiming to protect themselves from power glitches, optimize energy usage, and ensure operational continuity. Schneider Electric’s range of power meters, including the METSEPM5330, METSEPM5560, METSEPM5110, METSEPM89M2600, METSEPM8210, and METSEPM5330-2, offers reliable solutions tailored to diverse industrial needs.

Investing in a high-quality power meter not only prevents costly downtime but also boosts energy efficiency, enabling factories to stay competitive in an energy-conscious world. By leveraging the advanced features of Schneider Electric’s power meters, your factory can achieve unparalleled operational excellence.