Reliable PLC-Based Monitoring Solutions Ensuring Process Stability and Quality Control

In today’s highly competitive industrial landscape, maintaining process stability and ensuring quality control are essential for long-term success. Modern industries rely on automation to minimize errors, reduce downtime, and optimize operations. Among various automation technologies, PLC-based monitoring solutions have emerged as a cornerstone of reliable and efficient process management. These systems integrate seamlessly with variable speed drives, soft starters, and other automation equipment, making them indispensable in manufacturing, processing, and energy sectors.

This article explores how PLC-based monitoring enhances stability and quality, the role of devices like atv312h075s6 and ATS48D32Y, and why these solutions are critical for modern industrial operations.

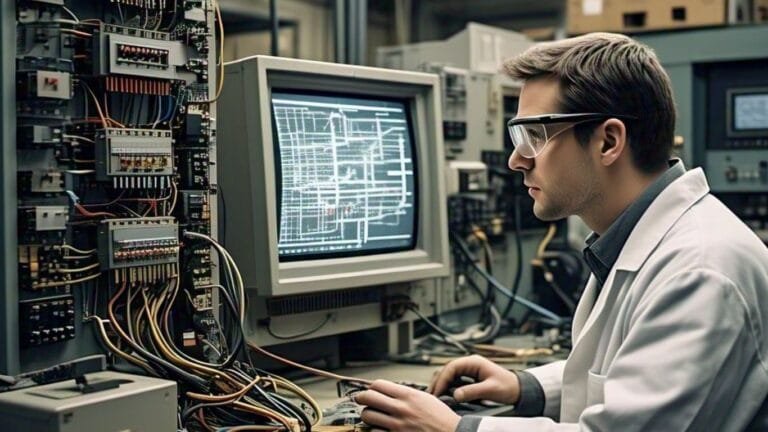

The Role of PLCs in Industrial Automation

What is a PLC?

A Programmable Logic Controller (PLC) is an industrial digital computer designed to handle real-time control applications. PLCs are engineered to withstand harsh environments and can manage complex automation tasks such as machine control, process sequencing, and data monitoring.

Why PLCs are Reliable

PLCs are chosen for their durability, modular design, and ease of programming. They can process thousands of input and output signals simultaneously, ensuring precise control. Their ability to integrate with variable speed drives and soft starters makes them ideal for applications demanding energy efficiency and consistent process performance.

Process Stability Through PLC-Based Monitoring

Real-Time Data Acquisition

PLC-based monitoring solutions continuously gather real-time data from sensors, drives, and actuators. This data is processed instantly to detect fluctuations, prevent errors, and maintain smooth operations.

Reducing Variability

In industries such as pharmaceuticals, food processing, and chemical manufacturing, even small variations can compromise product quality. PLCs minimize variability by maintaining strict control over temperature, pressure, flow, and other critical parameters.

Predictive Maintenance

By analyzing patterns and trends, PLC systems can predict potential failures before they occur. For example, if a motor shows unusual current consumption, the PLC can send alerts for maintenance, avoiding unexpected downtime.

Quality Control with PLC-Based Solutions

Automated Inspection

PLC-based systems can integrate with vision sensors and measurement devices to carry out real-time quality inspections. Defective products are automatically identified and separated, ensuring only high-quality output reaches the market.

Consistent Output

The repeatability of PLC-controlled operations ensures that every cycle of production follows the same sequence with identical accuracy. This level of consistency is vital for industries focused on mass production.

Compliance with Standards

By logging data and generating automated reports, PLC systems help industries comply with regulatory standards. This traceability not only enhances credibility but also simplifies audits and certifications.

Integration of PLCs with Drives and Soft Starters

The Importance of Drives in Process Control

Variable speed drives regulate motor speed and torque, improving energy efficiency and reducing wear and tear on equipment. A commonly used model, the atv312h075s6, is designed to provide reliable motor control while seamlessly integrating with PLC systems. This ensures precise speed regulation and better alignment with production requirements.

Role of Soft Starters in Smooth Operations

Soft starters gradually ramp up motor voltage, reducing mechanical stress during startup. The ATS48D32Y is an advanced soft starter that works effectively with PLC-based monitoring systems to extend motor life, minimize downtime, and optimize startup sequences.

Unified Control Architecture

When PLCs, variable speed drives like atv312h075s6, and soft starters such as ATS48D32Y are integrated, they form a unified control architecture. This enables synchronized operations, real-time monitoring, and enhanced fault detection. As a result, industries benefit from greater efficiency and reduced operational risks.

Benefits of PLC-Based Monitoring Solutions

Improved Efficiency

By automating repetitive and complex tasks, PLCs improve throughput while minimizing resource wastage. The integration of devices like atv312h075s6 ensures motors operate efficiently under varying loads.

Enhanced Reliability

Soft starters such as ATS48D32Y prevent sudden electrical surges and mechanical shocks, thereby increasing system reliability. With PLC monitoring, any irregularities are quickly addressed to maintain process continuity.

Cost Savings

Predictive maintenance and reduced downtime lead to substantial cost savings. Furthermore, energy-efficient operations powered by advanced drives lower utility expenses.

Scalability

PLC systems are modular, allowing industries to scale their operations without completely redesigning their automation framework. This flexibility is essential for growing businesses adapting to new market demands.

Real-World Applications of PLC-Based Monitoring

Manufacturing

In assembly lines, PLC-based monitoring ensures synchronized motor operations, precise conveyor speeds, and automated quality checks.

Food and Beverage Industry

Temperature, mixing ratios, and packaging processes are closely monitored to maintain consistency and safety standards.

Energy and Utilities

Power plants use PLCs to monitor turbines, pumps, and cooling systems, ensuring stable power generation and distribution.

Oil and Gas

From drilling operations to refinery management, PLC-based monitoring systems play a vital role in controlling hazardous processes while maintaining safety.

Overcoming Challenges with PLC-Based Solutions

Cybersecurity Risks

With growing connectivity, PLCs face cybersecurity challenges. Industries are addressing this by adopting secure communication protocols and robust firewalls.

Initial Investment

Although the upfront cost of PLC-based monitoring systems and equipment like atv312h075s6 and ATS48D32Y may be high, the long-term returns in reliability, efficiency, and quality control outweigh the initial expense.

Skilled Workforce

Implementing PLC-based systems requires trained engineers and technicians. Continuous training ensures optimal use of automation resources.

The Future of PLC-Based Monitoring

IoT and Smart Factories

The integration of Internet of Things (IoT) technology with PLCs is transforming industries into smart factories. Real-time cloud connectivity allows for advanced analytics, remote monitoring, and better decision-making.

AI and Machine Learning

Future PLC systems will leverage AI algorithms to optimize processes automatically, further enhancing stability and quality control.

Conclusion

PLC-based monitoring solutions are the backbone of modern industrial automation. By ensuring process stability and quality control, they help industries remain competitive in a demanding marketplace. The integration of reliable equipment like the atv312h075s6 variable speed drive and the ATS48D32Y soft starter enhances system efficiency, reduces downtime, and ensures long-term operational success.

As industries continue to evolve toward smart factories and digital transformation, PLC-based monitoring will remain central to achieving high performance, safety, and consistent quality. Businesses that invest in these solutions today position themselves for a future of efficiency, reliability, and growth.