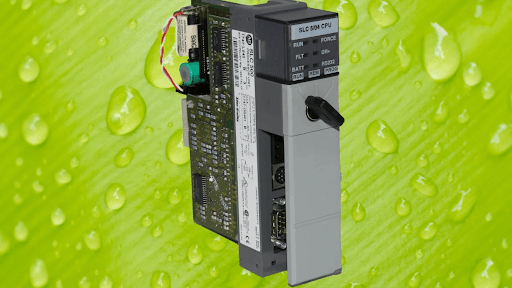

Why the 1747-L542 Remains a Reliable Choice for Industrial Automation

In the ever-evolving world of industrial automation, the demand for reliable, durable, and efficient controllers continues to grow. While many facilities upgrade to the latest control systems, there are still countless applications where proven, time-tested hardware remains the foundation of operations. The 1747-L542 Rockwell Automation processor is one such device that continues to demonstrate exceptional reliability and performance, even in today’s high-tech environments.

This article explores why the 1747-L542 remains a trusted solution in industrial automation and how it integrates effectively with modern PLCHMI systems to maintain productivity and efficiency.

Understanding the Role of the 1747-L542 in Automation Systems

The 1747-L542 Rockwell Automation processor belongs to a family of modular controllers widely recognized for their versatility and endurance. Designed for control applications across manufacturing, utilities, and process industries, it provides consistent and stable performance in demanding environments.

At its core, the 1747-L542 offers robust memory capacity, fast processing speed, and seamless communication capabilities that enable operators to maintain precise control over machines and production lines. These features make it suitable for discrete manufacturing, packaging, assembly, and many other automation tasks.

Key Features That Ensure Reliability

Proven Architecture

One of the main reasons the 1747-L542 continues to be a reliable choice is its solid architecture. Built on a stable design framework, it delivers dependable performance even after years of continuous operation. This reliability allows engineers to maintain confidence in their automation systems without frequent downtime or costly maintenance.

Flexibility and Scalability

The 1747-L542 supports multiple I/O configurations, communication modules, and expansion options. This flexibility enables users to scale their control systems according to specific process requirements. Whether managing a small production cell or a large integrated system, the processor adapts easily without requiring a complete redesign.

Seamless PLCHMI Integration

Integration with PLCHMI systems is a critical factor in modern industrial environments. The 1747-L542 interfaces efficiently with various HMI panels, enabling operators to visualize process data, monitor alarms, and make real-time adjustments. This combination of PLC and HMI functionality improves operational transparency and helps optimize decision-making on the production floor.

Rugged and Durable Design

Industrial environments are often harsh, with exposure to temperature fluctuations, dust, and vibration. The durable build of the 1747-L542 ensures consistent performance even under these conditions. Its reliability reduces the risk of unexpected system failures, helping maintain production continuity.

The 1747-L542 in Legacy and Modern Systems

Longevity and Backward Compatibility

One of the standout advantages of the 1747-L542 is its backward compatibility with existing system components. Many facilities have built their automation infrastructure around this controller, and replacing it would require significant investment. The continued availability and compatibility of the 1747-L542 make it easier to maintain or expand existing systems without disruption.

Integration with Modern Networks

Despite its long-standing presence in the industry, the 1747-L542 can still be integrated with modern control networks. With appropriate communication modules, it can connect to Ethernet, DeviceNet, and other network protocols. This allows it to communicate effectively with PLCHMI interfaces and other control devices, bridging the gap between legacy and modern technology.

Cost-Effective Maintenance

Replacing entire control systems can be costly and time-consuming. The 1747-L542 provides a cost-effective alternative by allowing facilities to retain existing infrastructure while still achieving reliable performance. Spare parts and support resources remain widely available, further extending the life of these systems.

Advantages of Using the 1747-L542 in Automation

1. Stability and Dependability

Few controllers can match the operational stability of the 1747-L542. Its proven track record in multiple industries has made it a trusted solution for engineers who prioritize consistent performance over the latest technological trends. When uptime and reliability are critical, this controller remains an ideal choice.

2. Simplified Programming and Maintenance

The programming structure of the 1747-L542 is straightforward, making it accessible for both experienced engineers and new technicians. The simplicity of the programming environment ensures faster setup, easier troubleshooting, and reduced maintenance time.

3. Efficient Communication and Data Handling

Modern automation demands fast and reliable data exchange between devices. The 1747-L542 supports efficient communication with PLCHMI systems, sensors, and actuators, enabling precise process control. This efficiency contributes to higher productivity and optimized system performance.

4. Support for Modular Expansion

The modular nature of the 1747-L542 allows engineers to customize their systems easily. By adding or replacing I/O modules, the controller can adapt to new production requirements without a complete system overhaul. This modularity is a key reason why it remains a preferred option for scalable automation projects.

How the 1747-L542 Enhances PLCHMI Applications

The integration between the 1747-L542 and PLCHMI technology delivers tangible operational benefits. Through real-time data exchange, operators can visualize critical metrics such as production rates, energy usage, and system status directly on the HMI screens. This transparency helps identify inefficiencies, detect issues early, and implement corrective actions promptly.

Moreover, PLCHMI integration enhances safety by allowing operators to monitor alarms and emergency conditions without physically approaching machinery. This human-machine synergy ensures safer, more efficient production environments.

Sustainability and Future Relevance

While new automation technologies continue to emerge, the 1747-L542 remains relevant due to its sustainability and adaptability. Many industries aim to reduce electronic waste by maintaining and upgrading existing systems instead of replacing them entirely. The reliability and longevity of the 1747-L542 align perfectly with these sustainability goals.

Additionally, with the right communication interfaces, this controller can continue operating effectively in hybrid systems that combine legacy hardware with modern digital platforms.

Conclusion

The 1747-L542 Rockwell Automation controller remains a cornerstone in industrial automation due to its unmatched reliability, flexibility, and integration capabilities. Its seamless compatibility with PLCHMI systems, durable construction, and proven performance make it a dependable choice for both legacy and modern applications.

For facilities seeking a balance between cost efficiency, performance, and long-term reliability, the 1747-L542 continues to stand as a trusted and practical solution in the evolving world of industrial automation.