How High Performance Controllers Improve Data Exchange In Complex Systems

Modern industrial environments rely on fast, accurate, and reliable data exchange to maintain efficiency and stability. As systems grow more interconnected, the role of high performance controllers becomes increasingly critical. These controllers act as the central intelligence of automated operations, ensuring that information flows smoothly between devices, subsystems, and decision-making layers without delay or distortion.

High performance controllers are designed to manage large volumes of data while maintaining precise timing and coordination. In complex systems where multiple processes occur simultaneously, even minor delays or data loss can lead to reduced productivity or costly downtime. Understanding how these controllers enhance data exchange helps organizations design more resilient and scalable automation architectures.

The Role of Advanced Communication in Automation

At the core of complex systems lies communication. Sensors, actuators, drives, and supervisory systems must constantly exchange information to keep operations synchronized. High performance controllers provide the processing power and communication capabilities required to handle this continuous flow of data.

These controllers support multiple communication paths and protocols, allowing them to interact with diverse devices across a system. By efficiently managing data traffic, they prevent bottlenecks and ensure that critical information reaches its destination on time. This capability is essential in environments where real-time responses are necessary for safety and quality control.

Managing Data Flow in High-Density Systems

In large-scale automation setups, thousands of data points may be generated every second. High performance controllers are optimized to process and route this data without compromising accuracy. They prioritize time-sensitive information and allocate resources dynamically based on system demands.

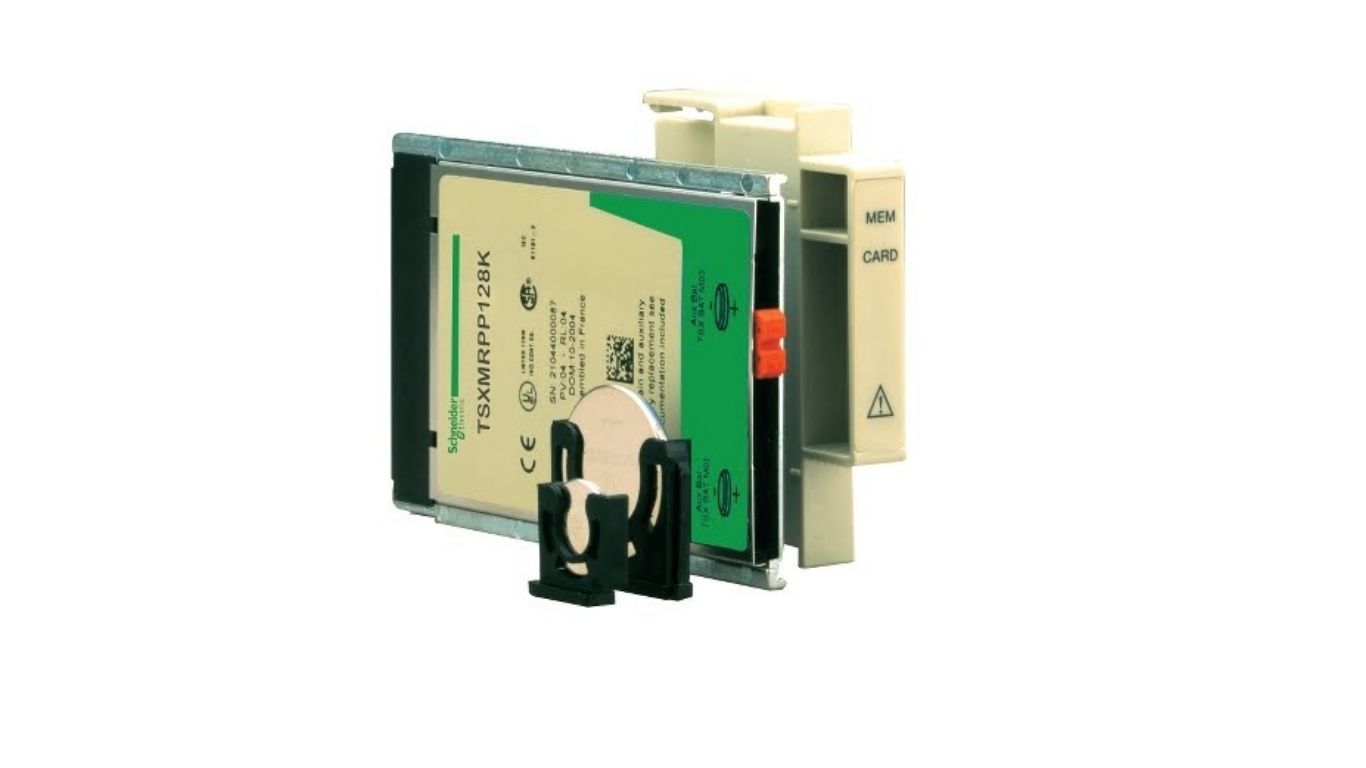

One example of a communication-focused controller solution is the TSXMRPC448K Modicon Premium Automation Platform, which represents a class of modules designed to support high-speed data exchange in demanding industrial environments. Such solutions demonstrate how dedicated communication processing can reduce network load on the main controller while improving overall system responsiveness.

Key Features That Enhance Data Exchange

High performance controllers incorporate several features that directly improve how data is exchanged across complex systems. These features work together to create a stable and efficient communication backbone.

High-Speed Processing Capabilities

Fast processors allow controllers to handle multiple communication tasks simultaneously. This reduces latency and ensures that incoming and outgoing data is processed without delay. High-speed processing is particularly important in systems that require precise synchronization between different machines or production stages.

By executing communication and control tasks in parallel, high performance controllers maintain consistent performance even as system complexity increases. This capability supports scalability, enabling systems to expand without sacrificing reliability.

Deterministic Communication Behavior

Deterministic communication ensures that data is transmitted within predictable timeframes. High performance controllers are designed to deliver consistent response times, which is essential for applications where timing accuracy directly affects outcomes.

In motion control, batch processing, or safety-related operations, deterministic data exchange allows systems to react precisely to changing conditions. This predictability reduces errors and enhances overall process stability.

Improving Reliability and Reducing Downtime

Reliable data exchange is a cornerstone of system availability. High performance controllers contribute to reliability by incorporating diagnostic and fault-handling mechanisms that monitor communication health.

Built-In Diagnostics and Monitoring

Advanced controllers continuously monitor network performance, data integrity, and device status. When communication issues arise, they can quickly identify the source and alert operators or higher-level systems.

Early detection of communication faults prevents minor issues from escalating into major failures. This proactive approach reduces unplanned downtime and supports faster maintenance responses.

Redundancy and Fault Tolerance

Many high performance controllers support redundant communication paths or components. If one path fails, the system can automatically switch to an alternative route, maintaining uninterrupted data flow.

This fault-tolerant design is particularly valuable in mission-critical applications where continuous operation is essential. By ensuring that data exchange remains intact under adverse conditions, controllers help protect productivity and safety.

Supporting Integration and Scalability

As industrial systems evolve, they must integrate new technologies and expand capacity. High performance controllers are built with flexibility in mind, making integration and scalability more manageable.

Seamless Integration with Diverse Devices

Modern controllers are compatible with a wide range of field devices and subsystems. Their ability to interface with different communication standards simplifies system design and reduces the need for custom solutions.

This interoperability allows organizations to adopt new equipment without overhauling existing infrastructure. Smooth integration ensures that data continues to flow efficiently as systems grow and change.

Enabling Future System Expansion

Scalability is a key advantage of high performance controllers. They are designed to accommodate increasing data volumes and additional communication nodes without degrading performance.

By supporting modular expansion, controllers enable gradual system upgrades. This approach minimizes disruption and protects long-term investment in automation infrastructure.

Enhancing Decision-Making Through Better Data Access

Accurate and timely data is essential for informed decision-making. High performance controllers ensure that operational data is readily available to supervisory and analytical systems.

Real-Time Data Availability

With efficient data exchange, controllers provide real-time visibility into system performance. Operators and control systems can respond quickly to deviations, optimizing processes and maintaining quality standards.

Real-time data access also supports advanced analytics and optimization strategies. By feeding reliable data into higher-level systems, controllers contribute to continuous improvement initiatives.

Supporting Advanced Control Strategies

High performance controllers enable complex control algorithms that rely on rapid data exchange. These strategies can improve efficiency, reduce energy consumption, and enhance product consistency.

As automation systems become more intelligent, the ability to exchange data quickly and reliably becomes even more critical. Controllers serve as the foundation for these advanced capabilities.

Conclusion

High performance controllers play a vital role in improving data exchange within complex systems. Through high-speed processing, deterministic communication, robust diagnostics, and scalable design, they ensure that information flows reliably across all levels of automation. In advanced applications, solutions such as those associated with the 140AII33000 Modicon Quantum Automation Platform illustrate how specialized modules can support efficient and dependable data handling in large-scale environments. By investing in capable controllers, organizations can build automation systems that are resilient, adaptable, and ready to meet future challenges.