How PLCs Ensure Consistency and Quality in Motor Winding

In the realm of modern computerization, Programmable Rationale Regulators (PLCs) have become irreplaceable apparatuses for guaranteeing accuracy, consistency, and quality in different assembling processes. One such basic application is engine winding, where even the smallest deviation can prompt shortcomings or disappointments. This article investigates how PLCs, like the 140CRA21210 and 140NRP31201, assume a crucial role in keeping up with consistency and quality in engine winding tasks.

The Significance of Consistency and Quality in Engine Winding

Engine winding is a fragile cycle that includes snaking wires around a stator or rotor to make electromagnetic fields. The nature of these windings straightforwardly influences the exhibition, effectiveness, and life expectancy of the engine. Conflicting winding strain, ill-advised wire arrangement, or erroneous turns can prompt engine disappointments, expanded energy utilization, and expensive margin time.

To address these difficulties, ventures are progressively going to PLC-based computerization frameworks. These frameworks smooth out the twisting system as well as guarantee that each engine created fulfills the most noteworthy guidelines of value.

How PLCs Improve Engine Winding Cycles

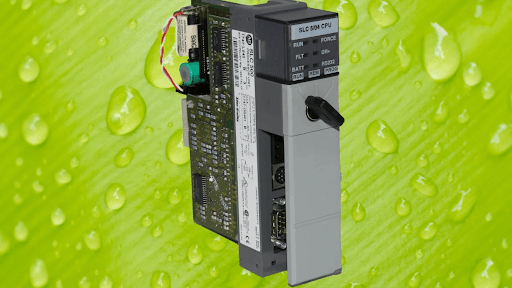

1. Accuracy Control with Cutting-Edge PLCs like 140CRA21210

The 140CRA21210 PLC is intended for high-accuracy control, making it ideal for engine winding applications. It guarantees that the winding machine works with demanding precision, keeping up with predictable strain and arrangement in the meantime.

Computerized Pressure Control: The PLC screens and changes the strain of the wire continuously, forestalling over-fixing or slack that could think twice about winding quality.

Accurate Turn Counting: With its high-level programming abilities, the 140CRA21210 guarantees that the right number of turns is accomplished for each winding, taking out human error.

2. Consistent Reconciliation with 140NRP31201 for Upgraded Execution

The 140NRP31201 module supplements the PLC framework by giving vigorous correspondence and control capacities. It guarantees consistent joining between the winding machine and different parts of the creation line.

Constant Observing: The 140NRP31201 empowers ongoing information assortment and checking, permitting administrators to quickly recognize and correct any deviations.

Blunder Identification and Remedy: By coordinating shortcoming location calculations, the framework can recognize issues, for example, wire breaks or misalignments, and naturally start remedial activities.

Key Advantages of Involving PLCs in Engine Winding

Further developed Consistency

PLCs take out the fluctuation related to manual winding cycles. Via robotizing the whole effort, they guarantee that each engine winding is indistinguishable, prompting uniform execution across all units.

Improved Quality Affirmation

With PLCs, quality registers are inserted with the cycle. The 140CRA21210 and 140NRP31201 work together to guarantee that each winding meets predefined particulars, diminishing the probability of deformities.

Expanded Efficiency

Robotization speeds up the twisting system while keeping up with high precision. This results in quicker creation cycles and higher results without compromising quality.

Diminished Margin time and Expenses

By limiting mistakes and imperfections, PLCs diminish the requirement for modifications and fixes. This recoveries time as well as brings down functional expenses.

True Utilizations of PLCs in Engine Winding

Enterprises, for example, auto, aviation, and buyer hardware depend intensely on PLC-controlled engine winding frameworks. For example:

Car: Electric vehicle makers use PLCs to deliver elite execution engines with steady-winding quality.

Aviation: Accuracy winding is basic for engines utilized in airplane frameworks, where unwavering quality is non-debatable.

Shopper Gadgets: PLCs guarantee that little engines in gadgets like robots and machines are twisted with accuracy and effectiveness.

End

The mix of cutting-edge PLCs like the 140CRA21210 and 140NRP31201 in engine winding cycles has reformed the business. These frameworks give unmatched accuracy, consistency, and quality, guaranteeing that each engine delivered satisfies the most elevated guidelines. As ventures keep on embracing mechanization, PLCs will stay at the forefront of advancement, driving effectiveness and dependability in engine fabricating.

By utilizing the capacities of these state-of-the-art PLCs, makers can improve their creation processes as well as gain an upper hand on the lookout. Whether it’s through constant checking, computerized mistake rectification, or consistent incorporation, PLCs are genuinely changing the eventual fate of engine winding.