Intergral Components in Industrial Automation

Intergral Components in Industrial Automation

Industrial automation has revolutionized manufacturing processes by integrating advanced technologies that ensure precision, efficiency, and scalability. At the heart of automation lies a variety of essential components, each designed to optimize specific tasks. Below, we delve into the significance of these components and how they contribute to seamless operations. Additionally, we provide insights into some of the best products in these categories, available through plchmi.shop.

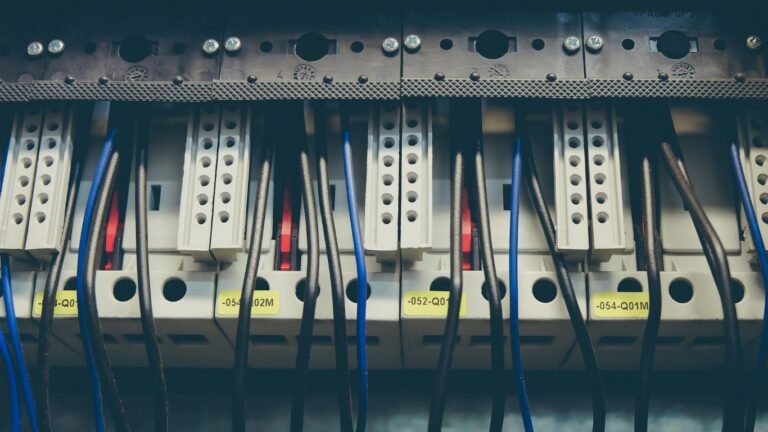

1. Input/Output Modules: Enhancing Connectivity and Control

Key Component: TSXDEY64D2K

Input/output (I/O) modules like the TSXDEY64D2K are critical in industrial automation as they bridge field devices and programmable logic controllers (PLCs). These modules:

- Facilitate Communication: Allow seamless data exchange between sensors and actuators.

- Ensure Precision: Provide accurate data capture and relay commands to execute complex processes.

- Support Scalability: Enable system expansion as operational demands grow.

By offering high reliability and easy integration, the TSXDEY64D2K helps industries maintain smooth workflows.

2. Operator Panels: Simplifying Human-Machine Interaction

Key Components:

- Schneider Electric Telemecanique Magelis XBT-F024510 Operator Panel

- Allen-Bradley PanelView 2711-K5A8L1

- XBTGT1100

Operator panels are indispensable in automation systems, acting as the primary interface for monitoring and controlling processes. Features include:

- Real-Time Feedback: Display critical metrics for process optimization.

- Ease of Operation: Intuitive touchscreens or keypads simplify complex tasks.

- Durability: Built to withstand harsh industrial environments.

The Schneider Magelis XBT-F024510 and Allen-Bradley PanelView 2711-K5A8L1 exemplify excellence in design, enabling operators to interact efficiently with machinery.

3. Networking Modules: Enabling Seamless Communication

Key Components:

Networking modules ensure interconnected systems operate as a cohesive unit. These components:

- Support Data Transfer: Provide high-speed connectivity between devices.

- Enhance Reliability: Reduce downtime through robust communication protocols.

- Promote Flexibility: Enable remote monitoring and control.

For instance, the BMXNOE0110H ensures efficient Ethernet-based communication, while the TSXETG100 bridges different network types seamlessly.

4. Digital and Analog Modules: Bridging the Physical and Digital Worlds

Key Components:

Digital and analog modules serve as translators between physical phenomena and digital systems:

- Digital Modules: Handle discrete signals (on/off states).

- Analog Modules: Process continuous signals, enabling finer control over variables like temperature and pressure.

The 140DDO36400 excels in output signal transmission, while the 140ACO13000 supports precise analog operations.

5. Human-Machine Interface (HMI) Terminals

Key Components:

HMIs like the HMIGTO1310 enable seamless interaction between humans and automated systems. Key benefits include:

- Customization: Allows tailored visualizations for different applications.

- Improved Efficiency: Reduces errors through intuitive controls.

- Real-Time Monitoring: Tracks performance metrics to identify inefficiencies.

This compact yet powerful HMI is perfect for industries demanding user-friendly interfaces.

6. Circuit Breakers and Protection Devices

Key Component:

Protection devices like the 499NMS25102 safeguard automation systems against electrical faults. Features include:

- Overload Protection: Prevents damage to connected components.

- Compact Design: Saves space in control panels.

- Enhanced Safety: Ensures compliance with industrial standards.

By incorporating such devices, industries can minimize downtime and maintenance costs.

Applications in Industrial Automation

- Manufacturing: Components like the Schneider Electric Telemecanique Magelis XBT-F024510 streamline production line operations.

- Energy Monitoring: Analog modules like the 140ACO13000 ensure accurate energy usage analysis.

- Process Automation: Networking modules such as the TSXETG100 enable seamless integration of remote facilities.

- Packaging: Digital I/O modules like the TSXDEY64D2K handle precise control of packaging lines.

Comparison Table of Key Products

| Component | Model | Functionality | Application |

|---|---|---|---|

| Input/Output Module | TSXDEY64D2K | Handles digital signals | Manufacturing and packaging |

| Operator Panel | XBTGT1100 | Simplifies human-machine interaction | Process monitoring |

| Networking Module | BMXNOE0110H | Ethernet-based communication | System integration |

| Analog Output Module | 140ACO13000 | Precise analog signal output | Energy and process control |

| HMI Terminal | HMIGTO1310 | Interactive user interface | Industrial process management |

| Protection Device | 499NMS25102 | Electrical fault protection | Control panel safety |

| Digital Output Module | 140DDO36400 | Discrete signal output | Assembly line automation |

Conclusion

The importance of high-quality components in industrial automation cannot be overstated. Each part, from I/O modules to HMIs, plays a vital role in enhancing productivity, safety, and operational efficiency. By investing in reliable products such as those listed above, industries can future-proof their systems and stay competitive in a fast-evolving market. Explore these and other top-notch automation components at plchmi.shop for unparalleled quality and performance.