PLC vs Traditional Control Systems What You Need to Know

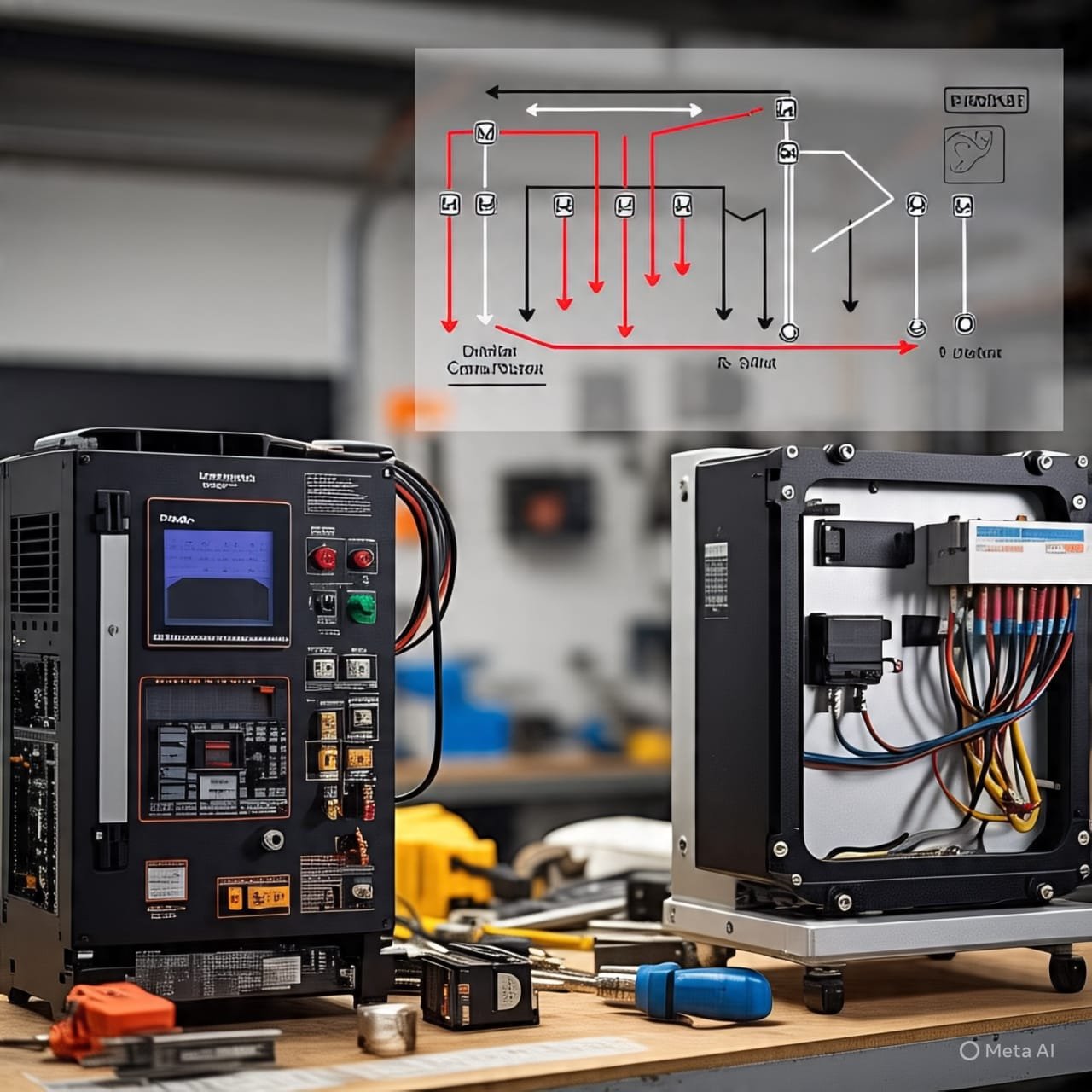

Control systems are the backbone of ultramodern robotization and artificial processes. Over the times, diligence have transitioned from traditional control systems to more advanced and flexible results, similar as Programmable sense regulators( PLCs). Understanding the differences between these systems can help businesses make informed opinions regarding robotization requirements. In this composition, we’ll explore the crucial distinctions between PLCs and traditional control systems, and punctuate how products like the HMIGTW7353 and ATS48C41YU are shaping the future of artificial control.

What Are Traditional Control Systems?

Traditional control systems have been used in colorful diligence for decades. These systems generally calculate on ingrained factors like relays, switches, and timekeepers to perform control functions. They’re generally less flexible and more complex when it comes to variations and scaling.

Crucial Features of Traditional Control Systems

Ingrained Circuits

factors are physically wired together, which can make troubleshooting and conservation delicate.

Limited Inflexibility

Any change to the control process frequently requires rewiring or replacing physical factors.

Homemade Operation

In numerous cases, traditional systems calculate on mortal intervention for adaptations and monitoring.

While these systems have been effective for simpler processes, they’re getting decreasingly obsolete in diligence where inflexibility, scalability, and perfection are critical.

What Are PLCs?

PLCs, or Programmable Logic regulators, are specialized computers designed for controlling artificial processes. They’re able of automating complex tasks and can be fluently programmed to meet the specific requirements of a process. Unlike traditional control systems, PLCs are much more protean, with features like remote monitoring, real- time control, and the capability to connect to a wide range of bias.

Crucial Features of PLCs

Programmable Sense

PLCs use software to program sense, making changes much easier without demanding to rewire the system.

Inflexibility

They can be acclimated for colorful operations, including complex robotization processes.

Remote Monitoring

numerous ultramodern PLCs support remote access, enabling drivers to cover and control systems from anywhere.

Integration with Other Systems

PLCs can be integrated with other bias like HMIs( mortal- Machine Interfaces) and SCADA systems for enhanced control and data analytics.

The shift to PLCs has revolutionized diligence, furnishing further robust, scalable, and effective results for robotization.

Crucial Differences Between PLC and Traditional Control Systems

1. Inflexibility and Scalability

Traditional control systems frequently bear significant reconfiguration and physical changes when spanning up or making variations. In discrepancy, PLCs offer superior inflexibility and scalability. With a PLC system, adding new detectors or factors can frequently be done through software without the need for rewiring.

2. Ease of conservation

While traditional systems bear homemade examination of individual factors, PLCs give further streamlined diagnostics and error shadowing. numerous PLCs, like those featuring the HMIGTW7353 HMI( Human- Machine Interface), offer stoner-friendly interfaces that display system status, enabling faster troubleshooting and reduced time-out.

3. Robotization and Control

PLCs are designed to automate complex processes with further perfection and trustability than traditional control systems. For illustration, the ATS48C41YU is an advanced soft starter that integrates seamlessly with PLC systems, furnishing smooth launch- ups and guarding motors from electrical faults. This position of integration between PLCs and factors ensures optimal performance and minimizes mechanical wear and tear.

The part of HMIs in PLC Systems

mortal- Machine Interfaces( HMIs) like the HMIGTW7353 play a critical part in enhancing the stoner experience with PLC systems. These interfaces act as the ground between drivers and machines, allowing for easy monitoring, control, and troubleshooting.

Features of the HMIGTW7353 HMI

Intuitive Interface

The HMIGTW7353 offers a graphical stoner interface( GUI) that’s intuitive and easy to navigate.

Real- Time Data Visualization

It provides real- time monitoring of artificial processes, displaying applicable data in an accessible format.

Enhanced Control

Drivers can modify settings, launch/ stop processes, and acclimate parameters directly from the HMI, icing lesser inflexibility in controlling operations.

The HMIGTW7353 is an illustration of how ultramodern PLC systems integrate seamlessly with human interfaces to give drivers with the tools they need for effective control and decision- timber.

The part of Soft Starters in PLC Systems ATS48C41YU

The ATS48C41YU is a crucial element in PLC systems, acting as a soft starter for motors. Soft starters are used to reduce the inrush current and mechanical stresses on outfit during the motor start- up phase, enhancing the overall trustability and lifetime of ministry.

Benefits of Using the ATS48C41YU Soft Starter

Smooth Motor Start- Up

It gradationally ramps up the motor speed, reducing the mechanical shock and electrical stress.

Energy Efficiency

By controlling the voltage applied to the motor, the ATS48C41YU helps reduce energy consumption during launch- up.

Protection Features

The soft starter provides protection against overloads, short circuits, and other electrical faults, Enhancing system trustability.

By integrating bias like the ATS48C41YU with PLC systems, diligence can insure smoother operations and better performance in motor- driven operations.

Conclusion

In conclusion, while traditional control systems served diligence well for numerous times, the shift toward PLCs offers clear advantages in terms of inflexibility, scalability, and ease of use. With products like the HMIGTW7353 HMI and the ATS48C41YU soft starter, businesses can make more effective, dependable, and cost-effective robotization systems.

ABB BREAKER 1S261-B63

ABB BREAKER 1S261-B63