The Importance of Key Components in Industrial Automation

Introduction

In the modern industrial landscape, automation has become the cornerstone of operational efficiency, precision, and scalability. Central to this transformation are the components that drive automation systems. From controllers to communication modules, these components form the backbone of smart industries. In this article, we explore the significance of various essential components in industrial automation, their role in enhancing productivity, and their impact on business outcomes.

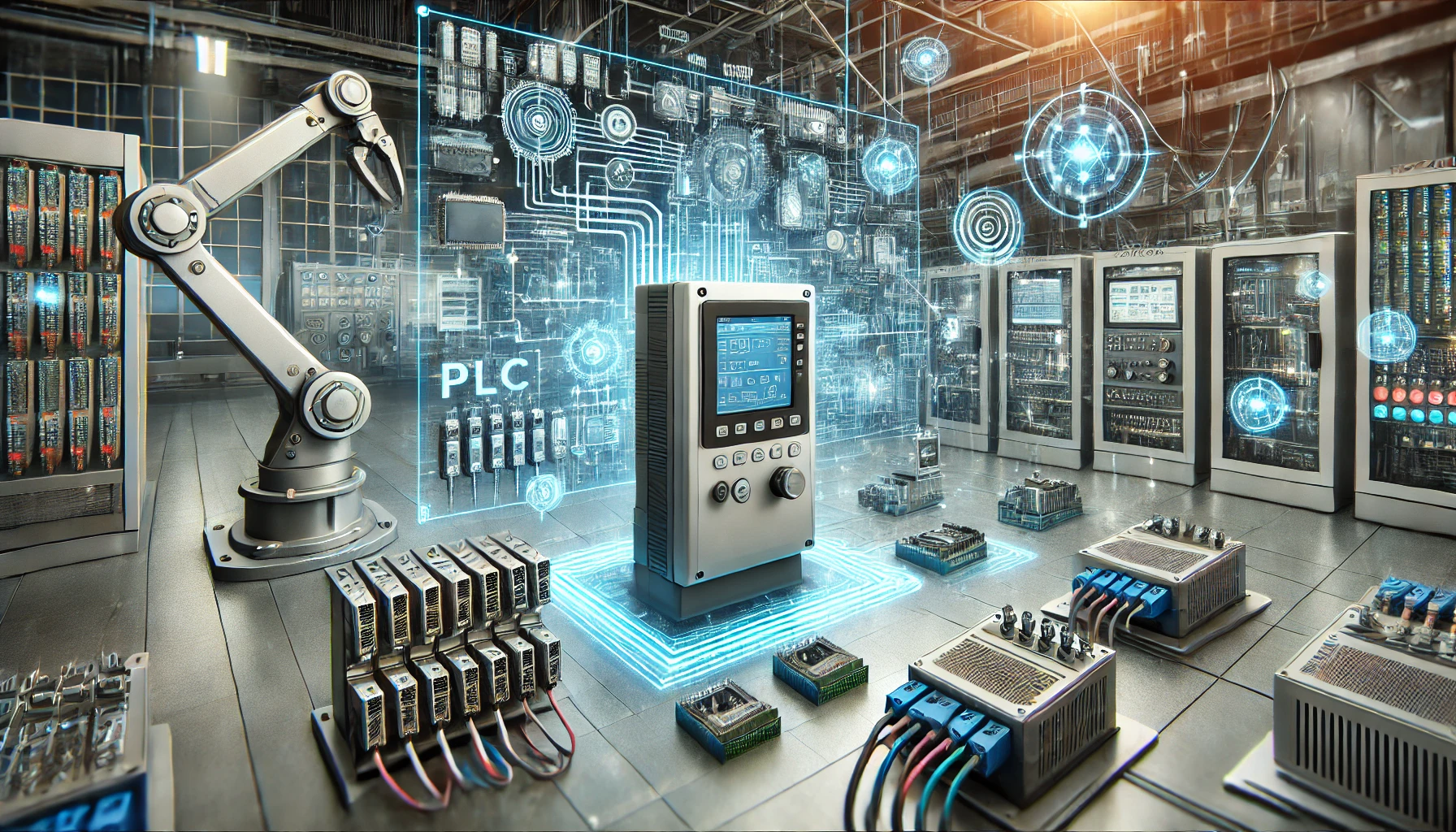

1. Programmable Logic Controllers (PLCs)

Programmable Logic Controllers (PLCs) are the heart of industrial automation. They are rugged, reliable, and designed to execute real-time control tasks efficiently. PLCs like the 140CPU67261 are pivotal in managing complex processes in industries like manufacturing, oil and gas, and energy.

Importance of PLCs in Industrial Automation:

- Flexibility: PLCs can be reprogrammed to suit different processes, reducing the need for physical rewiring.

- Reliability: They are designed to withstand harsh industrial environments.

- Scalability: PLCs allow seamless integration with additional modules to expand system capabilities.

2. Communication Modules

Effective communication between devices is vital for synchronized automation. Communication modules such as the 140CRA21210 and 140NOC78000 enable data exchange across controllers and devices.

Key Features:

- Real-time Data Transfer: Ensures efficient monitoring and control.

- Protocol Support: Compatibility with protocols like Ethernet/IP, Modbus, and Profinet.

- Network Redundancy: Reduces downtime and ensures system reliability.

3. Input/Output Modules

Input/Output (I/O) modules act as the interface between the PLC and field devices like sensors and actuators. Modules such as the 140DDO88500 and 140DDO36400 play a crucial role in signal conversion and data relay.

Significance:

- Enhanced Control: Accurate signal processing ensures precise machine operation.

- Versatility: Supports analog and digital signals, expanding application possibilities.

- Safety: Isolation features protect the system from electrical surges.

4. Power Meters

Power management is integral to sustainable industrial practices. Devices like the METSEPM8240 help monitor and optimize energy usage.

Benefits of Using Power Meters:

- Energy Efficiency: Identifies energy wastage and enables corrective measures.

- Cost Savings: Reduces operational costs by monitoring power consumption.

- Sustainability: Supports compliance with energy regulations and sustainability goals.

5. Specialized Processors

Advanced automation systems often require specialized processors like the 140CRP93200 for high-speed data processing and complex computations.

Advantages:

- High Performance: Handles multiple processes simultaneously.

- Integration: Seamlessly connects with other system components.

- Future-ready: Supports AI and machine learning integrations.

6. Redundancy Modules

In critical applications, system uptime is non-negotiable. Redundancy modules like the 140NRP31200 ensure operational continuity during failures.

Why Redundancy Matters:

- Minimized Downtime: Automatically switches to backup systems.

- Enhanced Reliability: Guarantees uninterrupted operations.

- Improved Safety: Protects sensitive processes and equipment.

7. Safety Modules

Safety is a paramount concern in industrial environments. Modules like the 140DDO15310 prioritize machine and personnel safety.

Core Features:

- Fail-Safe Design: Shuts down operations in case of anomalies.

- Compliance: Ensures adherence to safety standards like SIL and ISO.

- Integration: Works seamlessly with other automation components.

Benefits of Combining These Components

When integrated, these components create a robust automation ecosystem that offers:

- Enhanced Productivity: Streamlined processes and reduced manual interventions.

- Data-Driven Insights: Real-time analytics for better decision-making.

- Cost Efficiency: Reduced energy consumption and minimal downtime.

- Scalability: Adaptability to future technological advancements.

Conclusion

Industrial automation relies on a symphony of components working in harmony to deliver superior performance and reliability. Whether it’s PLCs, communication modules, or power meters, each plays a vital role in ensuring the success of automation systems. Businesses aiming to thrive in the Industry 4.0 era must invest in these high-quality components to unlock their full potential.

For more information about these essential products, explore the links below:

These products represent the cutting-edge of industrial automation technology, empowering industries to achieve operational excellence.