The Role of PLCs in Energy Efficiency and Sustainability

In today’s quickly advancing mechanical scene, vitality proficiency and maintainability have ended up pivotal components driving trade choices. With the expanding require to decrease operational costs and minimize natural affect, businesses are turning to progressed innovations like Programmable Rationale Controllers (PLCs) to optimize vitality utilization and improve maintainability endeavors. PLCs, known for their unwavering quality and adaptability, play a essential part in the robotization of mechanical forms, guaranteeing both operational proficiency and natural responsibility.

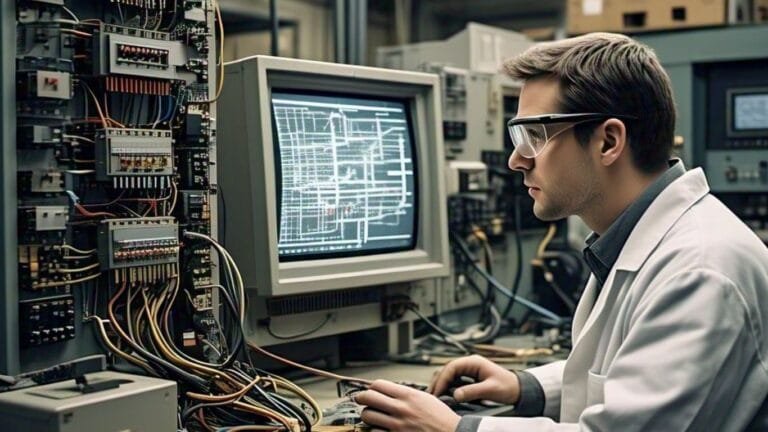

What are PLCs?

A Programmable Rationale Controller (PLC) is a advanced computer utilized for mechanization of mechanical forms. It screens inputs, forms them agreeing to a set of modified enlightening, and at that point triggers comparing yields. PLCs are regularly utilized in fabricating, vitality, and other businesses to control apparatus and forms with tall precision.

The Part of PLCs in Vitality Efficiency

Optimizing Operational Processes

PLCs are central to the robotization of different mechanical operations. By controlling apparatus and forms more effectively, PLCs offer assistance businesses diminish vitality utilization. For occasion, in frameworks like HVAC (Warming, Ventilation, and Discuss Conditioning) or lighting, PLCs can alter settings based on real-time conditions, guaranteeing that vitality is utilized as it were when required. This energetic control leads to diminished squander and critical reserve funds on vitality costs.

Checking Vitality Usage

With the capacity to coordinated sensors and meters, PLCs can ceaselessly screen vitality utilization over different gadgets and frameworks. This permits for real-time following and examination of control utilization, making a difference distinguish regions where vitality utilize is over the top or wasteful. The capacity to analyze this information empowers businesses to make educated choices approximately vitality optimization and actualize methodologies to cut down on pointless vitality consumption.

Making strides Machine Efficiency

PLCs are regularly utilized to control and screen apparatus in mechanical plants. By persistently evaluating machine execution and optimizing operational parameters, PLCs can guarantee that machines run at top proficiency. This anticipates abuse of vitality and makes a difference dodge energy-intensive breakdowns or wasteful aspects, specifically contributing to diminished generally vitality consumption.

PLCs and Sustainability

Decreasing Carbon Footprint

PLCs are instrumental in driving supportability endeavors inside businesses by diminishing vitality squander, which specifically impacts a company’s carbon impression. By fine-tuning operational forms and minimizing vitality utilization, PLCs offer assistance businesses contribute to the worldwide exertion to diminish nursery gas outflows. Whether it’s through the more productive utilize of control in a fabricating plant or optimizing mechanical warming frameworks, PLCs are key to bringing down energy-related natural impact.

Advancing Renewable Vitality Integration

PLCs play a crucial part in coordination renewable vitality sources into mechanical operations. In segments like sun powered and wind vitality, PLCs are utilized to screen and control vitality era and dispersion. By guaranteeing that renewable vitality frameworks are working ideally, PLCs offer assistance progress the productivity and viability of these frameworks, diminishing dependence on non-renewable vitality sources and advancing sustainability.

Prescient Upkeep for Sustainability

Another noteworthy commitment of PLCs to supportability is their part in prescient support. PLCs can screen gear conditions and foresee potential disappointments some time recently they happen. This proactive approach guarantees that apparatus works productively, lessening the chances of vitality wastage due to breaking down parts. Prescient support moreover decreases the require for intemperate repairs and substitutions, amplifying the life of gear and assist contributing to sustainability.

Key PLC Models Supporting Vitality Efficiency

Several progressed PLC models are outlined to maximize vitality productivity and progress by and large operational execution. Striking models, like the 170PNTI1020 and M6200A0A0B0A0B0R, offer one of a kind highlights that improve vitality administration and maintainability efforts.

170PNTI1020 PLC Model

The 170PNTI1020 PLC is outlined to optimize mechanical forms with its high-performance capabilities. It coordinating consistently into vitality administration frameworks, permitting for real-time checking and control of vitality utilization. With its progressed programming capabilities, the 170PNTI1020 PLC can computerize complex energy-saving assignments, such as controlling engines, warming components, or other power-hungry gadgets, in this manner decreasing pointless vitality utilize. Its adaptability moreover empowers integration with renewable vitality sources, making it a key player in driving sustainability.

M6200A0A0B0A0B0R PLC Model

The M6200A0A0B0A0B0R PLC is another cutting-edge show that gives fabulous control over energy-intensive forms. It offers strong information logging and analytics highlights, making it perfect for vitality checking and optimization assignments. With its capacity to communicate with other mechanical gear and frameworks, the M6200A0A0B0A0B0R PLC can guarantee that apparatus works at top vitality productivity, minimizing wastage and bringing down operational costs. Its progressed network alternatives empower the consistent integration of energy-saving methodologies over an whole facility.

Conclusion

PLCs are irreplaceable apparatuses for upgrading vitality effectiveness and advancing supportability in present day mechanical settings. By robotizing forms, observing vitality utilization, and empowering prescient support, PLCs offer assistance businesses diminish squander, spare costs, and diminish their natural affect. Models like the 170PNTI1020 and M6200A0A0B0A0B0R represent the basic part of PLCs in accomplishing vitality effectiveness objectives and cultivating a more feasible future for businesses worldwide.

As businesses proceed to center on lessening their carbon impression and making strides vitality utilization, PLCs will stay at the heart of endeavors to drive maintainability and vitality optimization.