Introduction

Modicon PLCs have established themselves as pivotal players in the world of industrial automation. Renowned for their reliability, innovation, and versatility, Modicon PLCs continue to influence industries worldwide. This article aims to delve deeply into the various facets of Modicon PLCs, exploring their software, programming capabilities, product range, and how they integrate seamlessly into modern industrial systems. We will also compare some key models and discuss Schneider Electric’s vital role in advancing Modicon technology, ensuring businesses can harness the full potential of automation.

The Evolution of Modicon PLC

Modicon: The First PLC

The inception of the Modicon PLC marked a significant turning point in automation technology. Launched in 1968, Modicon was the first company to create a Programmable Logic Controller (PLC). This groundbreaking development revolutionized industrial control systems, transitioning from traditional relay-based control systems to a more flexible, programmable format.

The Importance of Modicon in Automation History

Before PLCs, control systems relied heavily on intricate relay systems, which were not only cumbersome but also prone to failure and hard to troubleshoot. The introduction of Modicon PLCs made programming more accessible and enabled real-time adjustments to manufacturing processes. This shift significantly improved operational efficiency, reliability, and reduced downtime.

Milestones in Modicon’s Development

Over the years, Modicon has continued to innovate. Notable milestones include the introduction of advanced communication protocols, enhanced processing capabilities, and user-friendly programming environments. These advancements have positioned Modicon PLCs as a trusted choice for a myriad of applications in sectors such as manufacturing, energy, and transportation.

Understanding Modicon PLC Software

What is Modicon PLC Software?

Modicon PLC software is a suite of tools designed to program, configure, and manage Modicon PLCs. It serves as the interface between operators and the PLC hardware, enabling users to create control programs that automate industrial processes.

Key Features of Modicon PLC Software

- User-Friendly Interface: The software offers a graphical interface that makes it easy to visualize and design control logic.

- Real-Time Monitoring: Operators can monitor PLC performance and troubleshoot issues in real-time, significantly enhancing system reliability.

- Versatile Integration: The software can integrate with various hardware components, making it adaptable for different industrial environments.

Advantages of Using Modicon PLC Software in Automation

Utilizing Modicon PLC software provides numerous advantages, including:

- Increased Efficiency: Streamlined programming and monitoring reduce operational costs.

- Enhanced Flexibility: Users can easily modify programs to adapt to changing industrial needs.

- Robust Support: Extensive documentation and community support simplify the learning curve for new users.

Integrating Modicon Software with Other Systems

Modicon PLC software can easily integrate with other automation systems, including SCADA and HMI systems. This integration allows for centralized monitoring and control, providing operators with a holistic view of their operations.

Overview of Modicon PLC Products

Range of Modicon PLC Products

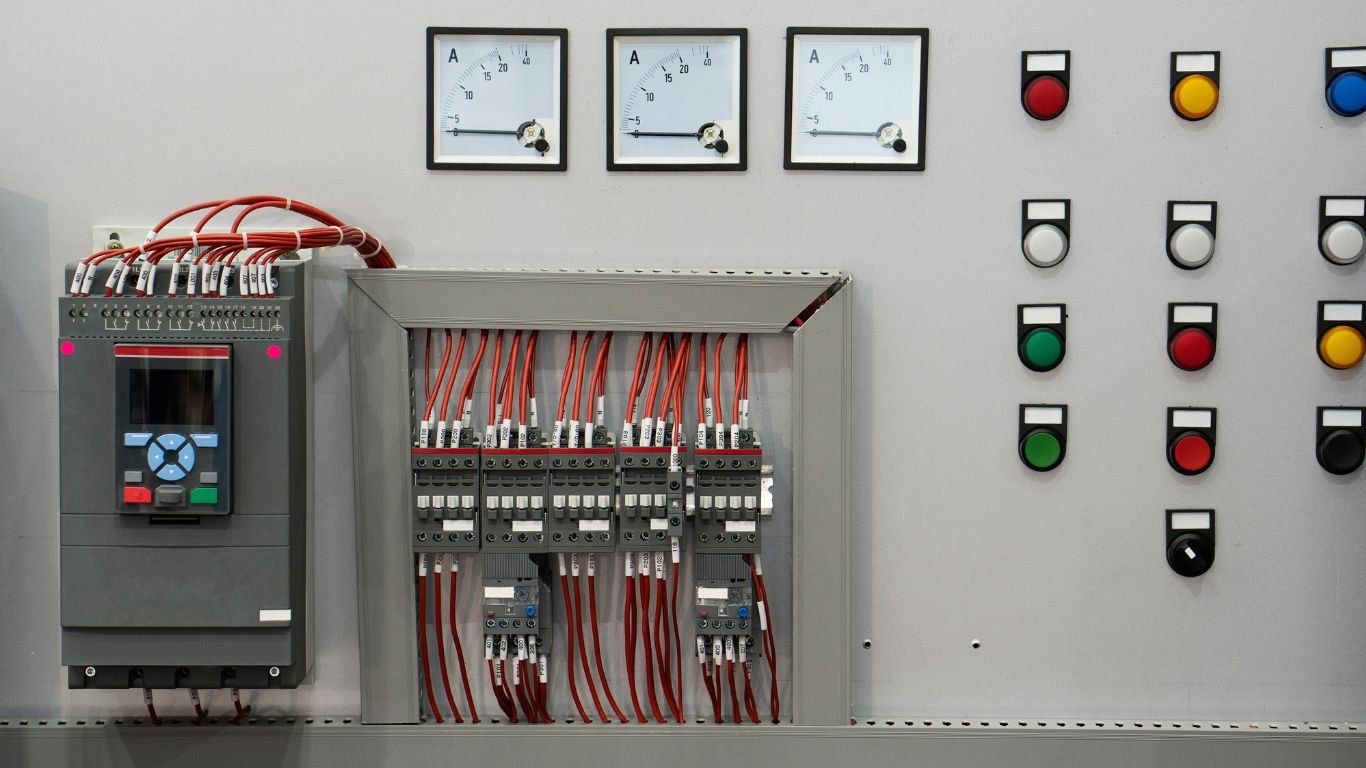

Modicon offers a comprehensive range of PLC products, catering to various industrial applications. From basic models designed for small-scale operations to advanced systems capable of handling complex processes, Modicon has a solution for everyone.

Modicon PLC Models

The range of Modicon PLC models includes compact units for simple applications, modular systems for flexible configurations, and high-performance models for demanding tasks. Each model is designed with specific industrial requirements in mind.

How Modicon Products Meet Industrial Needs

Modicon PLCs are built to withstand challenging environments while delivering consistent performance. Their robust designs and customizable features make them suitable for industries like automotive, food and beverage, oil and gas, and pharmaceuticals.

Specific Use Cases for Modicon Products

- Manufacturing: Automating assembly lines for increased productivity.

- Energy Management: Controlling renewable energy systems and optimizing power distribution.

- Water Treatment: Managing complex water treatment processes for efficiency and compliance.

Modicon PLC Programming: A Flexible Approach

Basics of Modicon PLC Programming

Programming Modicon PLCs involves defining how the PLC should respond to various inputs, thereby controlling outputs effectively. This process is critical for automating tasks and ensuring efficient operations.

Programming Languages Used in Modicon PLC

Modicon PLCs support multiple programming languages, including:

- Ladder Logic (LD): Ideal for electrical engineers, LD mimics relay logic.

- Structured Text (ST): A high-level language that resembles traditional programming languages, making it accessible for software developers.

- Function Block Diagram (FBD): Provides a visual approach to programming, using blocks to represent functions.

User-Friendly Interfaces for Seamless Programming

The programming interfaces for Modicon PLCs are designed for usability. Users can drag and drop elements to create logic diagrams, facilitating quick program development and testing.

Best Practices in Modicon PLC Programming

- Modular Design: Break programs into smaller, reusable modules for easier debugging and maintenance.

- Documentation: Keep thorough documentation of programs for future reference and team collaboration.

- Testing: Always simulate programs before deployment to catch any potential errors.

Modicon PLC Models: Tailored Solutions for Every Need

Overview of Popular Modicon PLC Models

When considering Modicon PLCs, several models stand out for their features and capabilities. Let’s explore some of the most popular options available.

140CPU67261: A High-Performance Model

The 140CPU67261 is recognized for its exceptional processing speed and large memory capacity, making it an ideal choice for complex automation tasks requiring real-time data processing.

140CRA21210: Powerful & Efficient

Designed for efficiency, the 140CRA21210 model excels in industrial environments where high performance and reliability are paramount. Its flexible architecture supports a variety of industrial applications.

140CRA93200: Designed for Complex Systems

The 140CRA93200 model is tailored for highly complex automation systems. It offers superior networking capabilities and integrates seamlessly into larger control systems.

140CRP93200: Advanced Redundancy and Communication

For applications that demand high availability, the 140CRP93200 model is perfect. Its advanced redundancy features ensure uninterrupted operation and reliable communication.

Comparative Analysis of Key Features

Here’s a brief comparison of these models based on their performance, memory, and best use cases:

| Model | Processing Speed | Memory Capacity | Networking | Redundancy | Best Use Case |

|---|---|---|---|---|---|

| 140CPU67261 | High | Large | Basic | None | Complex Systems |

| 140CRA21210 | Moderate | Medium | Advanced | Limited | Industrial Tasks |

| 140CRA93200 | High | Large | Advanced | Yes | Complex Systems |

| 140CRP93200 | High | Medium | Advanced | Yes | Redundancy-Based |

Modicon PLC Configurator: Customizing Your Automation Experience

What is the Modicon PLC Configurator?

The Modicon PLC Configurator is a powerful tool that helps users tailor their PLC setups according to specific needs. This configurator evaluates project requirements and recommends suitable Modicon PLC models and configurations.

How the Configurator Simplifies Setup and Integration

By guiding users through the selection process, the configurator simplifies the often-complex integration of Modicon PLCs into existing systems. It ensures that selected components work together seamlessly, reducing setup time and costs.

Utilizing the Configurator for Tailored Solutions

Operators can input specific project parameters, such as desired features, environmental conditions, and budget constraints. The configurator will then suggest tailored solutions that meet these criteria, enhancing the efficiency of the procurement process.

Schneider Electric and Modicon: A Strong Partnership

Schneider PLC and Its Contribution to Modicon’s Success

Since its acquisition of Modicon in 1996, Schneider Electric has played a crucial role in the brand’s continued innovation and success. Schneider Electric’s extensive resources and expertise have allowed Modicon to evolve its products and technology significantly.

Impact of Schneider Electric on Modicon Development

Under Schneider Electric’s leadership, Modicon PLCs have benefitted from advanced research and development initiatives. The integration of cutting-edge technology has led to improvements in communication protocols, energy efficiency, and user interfaces.

Comparison Table of Modicon PLC Models

The following table summarizes the key features of popular Modicon PLC models, allowing for an easy comparison when selecting the right solution for your automation needs.

| Model | Processing Speed | Memory Capacity | Networking | Redundancy | Best Use Case |

|---|---|---|---|---|---|

| 140CPU67261 | High | Large | Basic | None | Complex Systems |

| 140CRA21210 | Moderate | Medium | Advanced | Limited | Industrial Tasks |

| 140CRA93200 | High | Large | Advanced | Yes | Complex Systems |

| 140CRP93200 | High | Medium | Advanced | Yes | Redundancy-Based |

Future Trends in Modicon PLC Technology

Innovations on the Horizon

As technology evolves, so do the capabilities of Modicon PLCs. Anticipated innovations include enhanced AI and machine learning integration, improving predictive maintenance and operational efficiency.

Embracing Industry 4.0

The shift toward Industry 4.0 presents exciting opportunities for Modicon PLCs. These controllers are increasingly incorporating IoT connectivity, allowing for real-time data analysis and decision-making.

Sustainability and Efficiency Focus

As industries strive for sustainability, Modicon is focusing on developing energy-efficient PLCs that help reduce overall environmental impact. This includes energy management systems that optimize power consumption across operations.

Conclusion

Modicon PLCs remain a leading choice for industrial automation, offering innovative solutions that are both reliable and versatile. From the pioneering Modicon software to advanced models like the 140CPU67261 and 140CRA93200, Modicon provides a comprehensive suite of products designed to meet diverse automation needs. The support of Schneider Electric has further strengthened Modicon’s position in the market, ensuring that businesses can confidently implement automation solutions that drive efficiency and growth. As we move forward into an era of Industry 4.0 and smart manufacturing, Modicon is poised to continue leading the way in industrial automation technology.

Furthermore, details are available on our website and also on Pinterest.

FAQs

- What is Modicon PLC software used for? The Modicon PLC software is used to program and operate Modicon PLCs, facilitating automation across various industrial applications.

- Which Modicon PLC model is best for my application? The best model depends on your specific requirements, including processing speed, memory, networking capabilities, and the complexity of the tasks to be automated. The Modicon PLC Configurator can help guide your choice.

- Can Modicon PLCs integrate with other systems? Yes, Modicon PLCs can integrate seamlessly with various automation systems, including SCADA and HMI systems, for centralized monitoring and control.

- What programming languages are supported by Modicon PLCs? Modicon PLCs support multiple programming languages, including Ladder Logic, Structured Text, and Function Block Diagram.

- How can I ensure efficient Modicon PLC programming? Following best practices such as modular design, thorough documentation, and extensive testing will help ensure your Modicon PLC programming is efficient and effective.