The Backbone of Industrial Automation: Understanding PLCs

Programmable Logic Controllers (PLCs) are integral to modern industrial automation, serving as the backbone for controlling machinery and processes across various sectors. As industries evolve and technology advances, PLCs have become more sophisticated, reliable, and essential for operational efficiency. This article delves into the intricacies of PLCs, their key features, benefits, applications, and highlights some notable models available in the market.

What is a PLC?

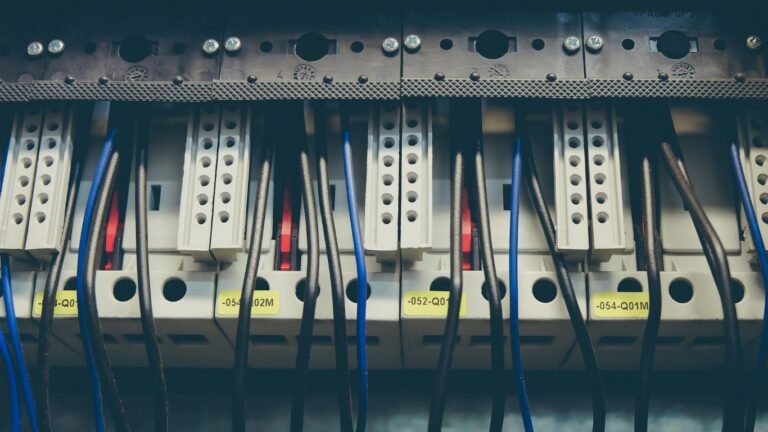

A PLC is a type of digital computer specifically designed for automating electromechanical processes. These include control systems for machinery on factory assembly lines, amusement rides, lighting fixtures, and other applications requiring high reliability, ease of programming, and process fault diagnosis. The primary role of a PLC is to receive inputs from various sensors and devices, process this information according to predefined logic, and control outputs such as motors, valves, and actuators.

Key Features of PLCs

| Feature | Description |

|---|---|

| Modular Design | PLCs have a modular design allowing for customization and scalability based on application needs. The 140CPS41400 is an example of a model accommodating various input and output modules. |

| High Processing Speed | Engineered for rapid data processing, PLCs enable real-time monitoring and control. The 1769-PA4-A power supply supports these operations by providing stable power. |

| User-Friendly Programming | Most PLCs utilize graphical programming languages, such as ladder logic, which make them accessible to users with varying technical backgrounds. The 140CPS22400 is noted for its intuitive programming environment. |

| Durability and Reliability | PLCs are built to withstand harsh industrial environments, ensuring consistent performance. The 140CPS12420 exemplifies a robust controller for demanding applications. |

| Networking Capabilities | Many PLCs support networking, allowing integration with other devices. The 6EP13331LB00 offers exceptional connectivity options for seamless communication. |

Advantages of Using PLCs

- Increased Efficiency: PLCs streamline operations by automating repetitive tasks, minimizing human error, and enhancing productivity.

- Flexibility: Easily reprogrammable, PLCs adapt to changing production requirements, making them a cost-effective solution for various applications.

- Cost-Effectiveness: While the initial investment can be significant, long-term savings from improved efficiency and reduced downtime can be substantial.

- Real-Time Monitoring: PLCs provide real-time data, enabling operators to make informed decisions quickly, which is crucial in time-sensitive processes.

Applications of PLCs

PLCs are versatile and find applications in numerous industries, including:

- Manufacturing: Controlling assembly lines and managing robotic devices.

- Food and Beverage: Automating bottling, packaging, and food processing.

- Water Treatment: Managing pumps, valves, and chemical dosing systems.

- Transportation: Used in traffic control systems, railway signaling, and toll collection.

- Building Automation: Optimizing HVAC systems and lighting control for energy efficiency.

Popular PLC Models

Several PLC models stand out in the market, each offering unique features and benefits. Here’s a summary of some notable models:

| Model Name | Key Features | Link |

|---|---|---|

| 140CPS11420 | Robust design, versatile for various industrial applications. | View Product |

| 140CPS11420 (Used) | Cost-effective option for reliable performance at a lower price. | View Product |

| 1756-M16SE | High-performance controller for demanding applications. | View Product |

| XP502-2 | Ideal for complex operations requiring advanced processing capabilities. | View Product |

| 140CPS12420 (Used) | Reliable performance and adaptability for various industrial applications. | View Product |

Conclusion

Programmable Logic Controllers (PLCs) are critical components in the landscape of industrial automation, providing essential functionalities that enhance efficiency, reliability, and adaptability. With various models available, such as the 140CPS41400 and 140CPS22400, businesses can choose the right solution to meet their specific automation needs. As industries continue to evolve, PLCs will remain vital, driving innovation and supporting the future of automation.

For those interested in exploring these models further, detailed specifications and purchasing options can be found at the provided links. Embracing PLC technology is a step toward optimizing operations and achieving greater success in today’s competitive industrial environment.